Ordering scan patterns for cost-effective test and diagnosis

To control test cost, the order in which test patterns are created and applied matters…

For controlling test cost, pattern order matters

A common way to control production test cost is to create and apply the test patterns in the most efficient sequence that also detects the most defects and correctly diagnoses the root cause of failures. Herein lies the challenge: how to determine the ideal order in which to create multiple pattern types and apply scan patterns on the tester. Those two orderings (creating and applying) can be different, of course, or else your job would be boring.

We’ve just published a new whitepaper that covers the best practices for determining the best order of pattern creation. Spoiler: give priority to creating patterns that have the most strict detection requirements, such as path delay patterns.

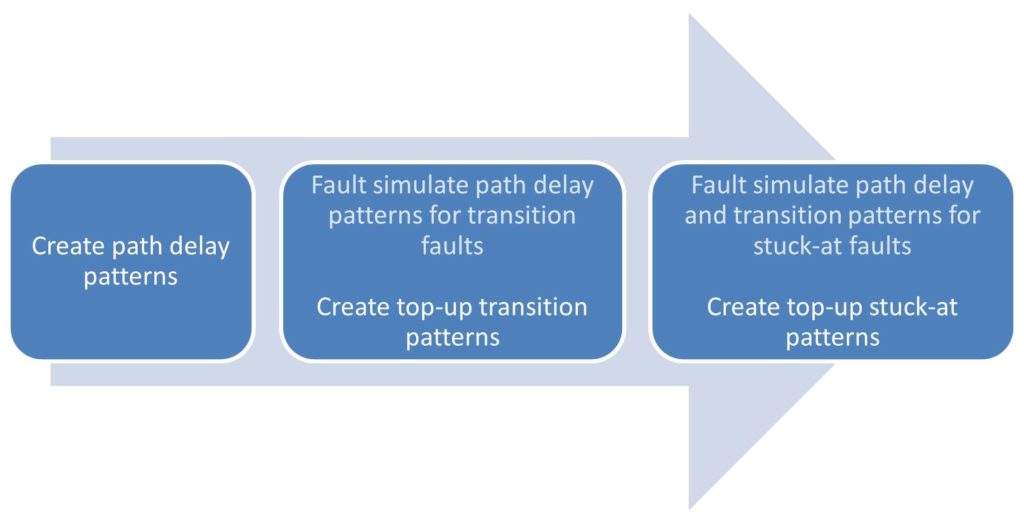

Figure 1 A typical pattern creation process.

Test patterns can be grouped into three main categories.:

- Chain test patterns

- At-speed patterns, which include transition, path delay, timing-aware, delay cell-aware, delay bridge, and delay functional User Defined Fault Modeling (UDFM) patterns.

- Static patterns, which include stuck-at, toggle, static cell-aware, static bridge, and static functional UDFM.

We offer an ordered list of scan pattern types in the whitepaper that you can use as a guideline for creating and fault simulating each pattern type in order to achieve the smallest pattern set. Smallest pattern set equals lower test cost, which is a primary goal of production test of ICs today. Once you get field returns and manufacturing yield data, the pattern sets can be further optimized to be more efficient and detect more defects in silicon.

Note that the most efficient sequence for creating the smallest pattern set is different than the ideal order for tester application. So, save all pattern sets separately so that they can be applied on the tester according to the appropriate test phase and desired defect detection.

During the tester application, the order in which different types of patterns are applied depends on whether it is a “go/no go” production test, which stops testing at the first failure, or datalogging of some or all failures is needed for diagnosis. We go into this flow in more detail in our new whitepaper Effective Ordering and Application of Scan Patterns for cost, Quality, and Diagnosis Data Collection.

In summary, there are best practices for ordering of test pattern types whether for pattern creation or for tester application. Your ideal pattern ordering may vary, depending on desired test coverage, cost requirements, and data collection for diagnosis.