Virtual and augmented reality in the smart factory / IPC APEX EXPO

Change your perception of how work gets done

Don’t miss Siemens PLM at IPC APEX EXPO 2018 , Tuesday, February 27 through Thursday, March 1, at the San Diego Convention Center, Exhibit Hall B2, Booth #2621. Meet with Siemens experts and learn about new advancements in digital manufacturing technology. Siemens PLM and Mentor help companies digitalize manufacturing and the process of turning innovative product ideas and raw materials into real products.

Visitors at IPC APEX EXPO will learn about the innovative technologies that we have to help electronics manufacturers digitalize manufacturing and realize innovation.

A smart factory is a fully digitalized factory model representing a production system, a digital twin for production, which is completely connected to a product lifecycle management (PLM) data repository via sensors, supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs) and other automation devices.

Key enablers in the smart factory are virtual and augmented reality devices and techniques.

Virtual reality: Validate process plans faster and improve training for production execution

Learning in the smart factory is facilitated by the use of virtual reality devices and techniques. These devices and techniques enable production employees to walk through the production lines inside the production system in a virtual manner, well before they will be installed on the shop floor. Using Siemens software and these virtual reality tools, maintenance crews are trained on how to maintain these complex manufacturing systems, while the production teams learn how to use the systems and execute the production tasks.

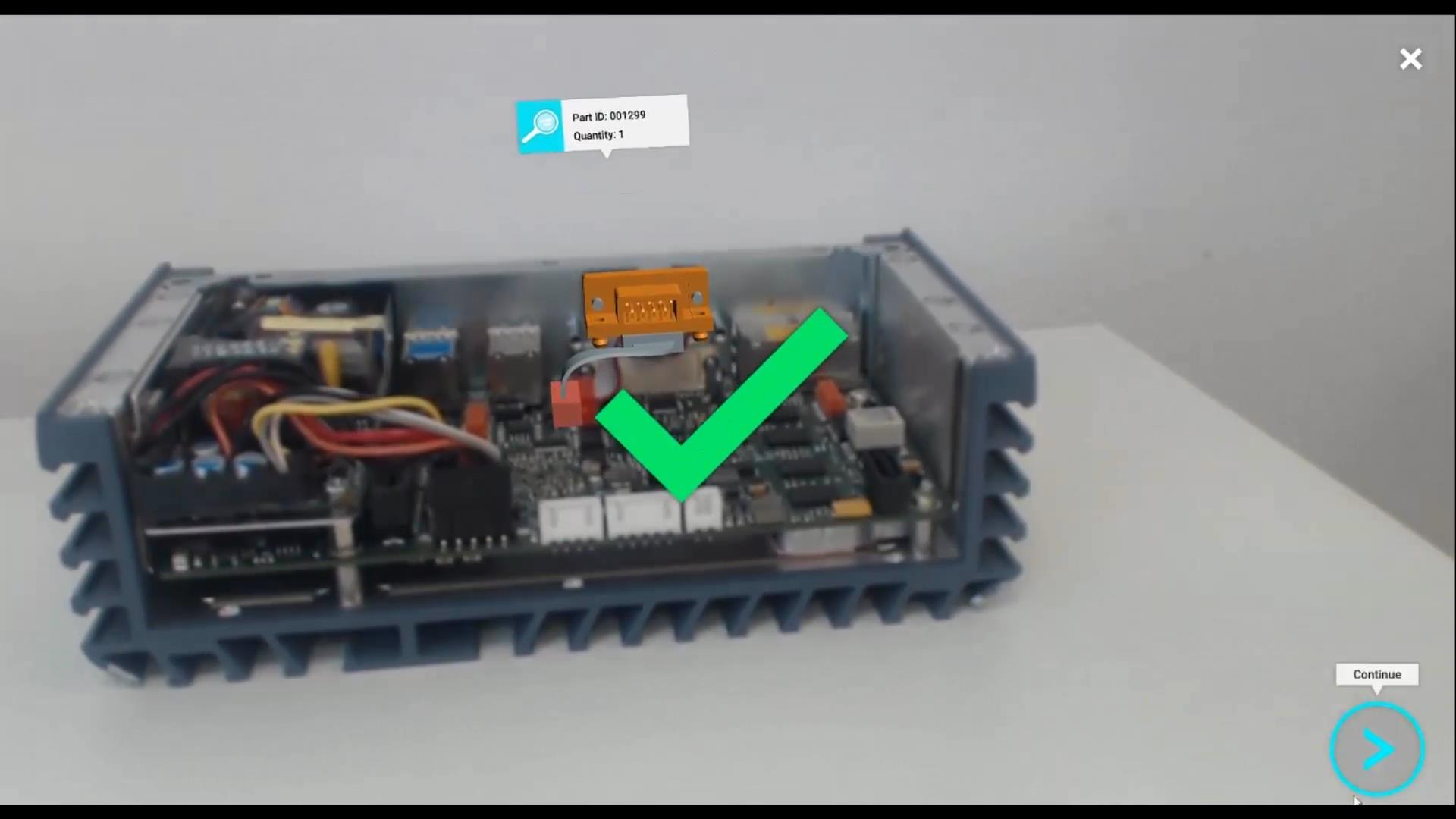

Augmented Reality: Deliver more meaningful instructions into production and ensure successful installation

Once the physical production line is established, shop-floor workers can use Siemens software with augmented reality devices and techniques to guide them through the production process, to overlay process animations of the next production step on the real part or product, and to validate that workers executed the process correctly. Consequently, workers are able to maneuver robots and assistors so they can get to spots that are not otherwise reachable.