Video: Plant Simulation in container glass manufacturing

Watch this video to learn how to benefit from Tecnomatix Plant Simulation in the container glass manufacturing industry.

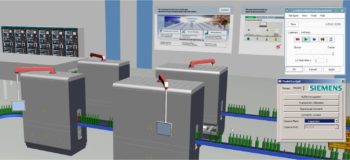

Digitalization is the essential next step in glass manufacturing. It is founded on the industry’s high level of automation with the digital manufacturing solutions provided by Tecnomatix Plant Simulation.Siemens is making a key element of digitalization available for the glass industry. Tecnomatix Plant Simulation lets users simulate the sequence of an entire glass line. That means they can use the virtual representation of a plant to optimize its operation and maintenance in real time. The digital twin lets you perform a range of scenarios to test whether the production plant will meet the desired requirements.

And, thanks to Tecnomatix Plant Simulation the opportunities are limitless. The program lets you conveniently monitor transport routes and production stages within the plant, such as quality control and palettizing in the case of container glass manufacturing. The digital twin also lets you simulate outages in individual plant units during operation.

How will an outage in one section of the IS machine effect ongoing production? Simulating these scenarios helps plant operators identify potential weak points in the plant and put the appropriate measures in place.

How will you benefit from using Tecnomatix Plant Simulation in container glass manufacturing? Tecnomatix helps you make the right decisions, reduce costs, and improve the efficiency of your plant. The program helps shorten your time-to-market by enabling end-to-end design and analysis of your entire plant. Tecnomatix smooths your path to digitalization in the glass industry.