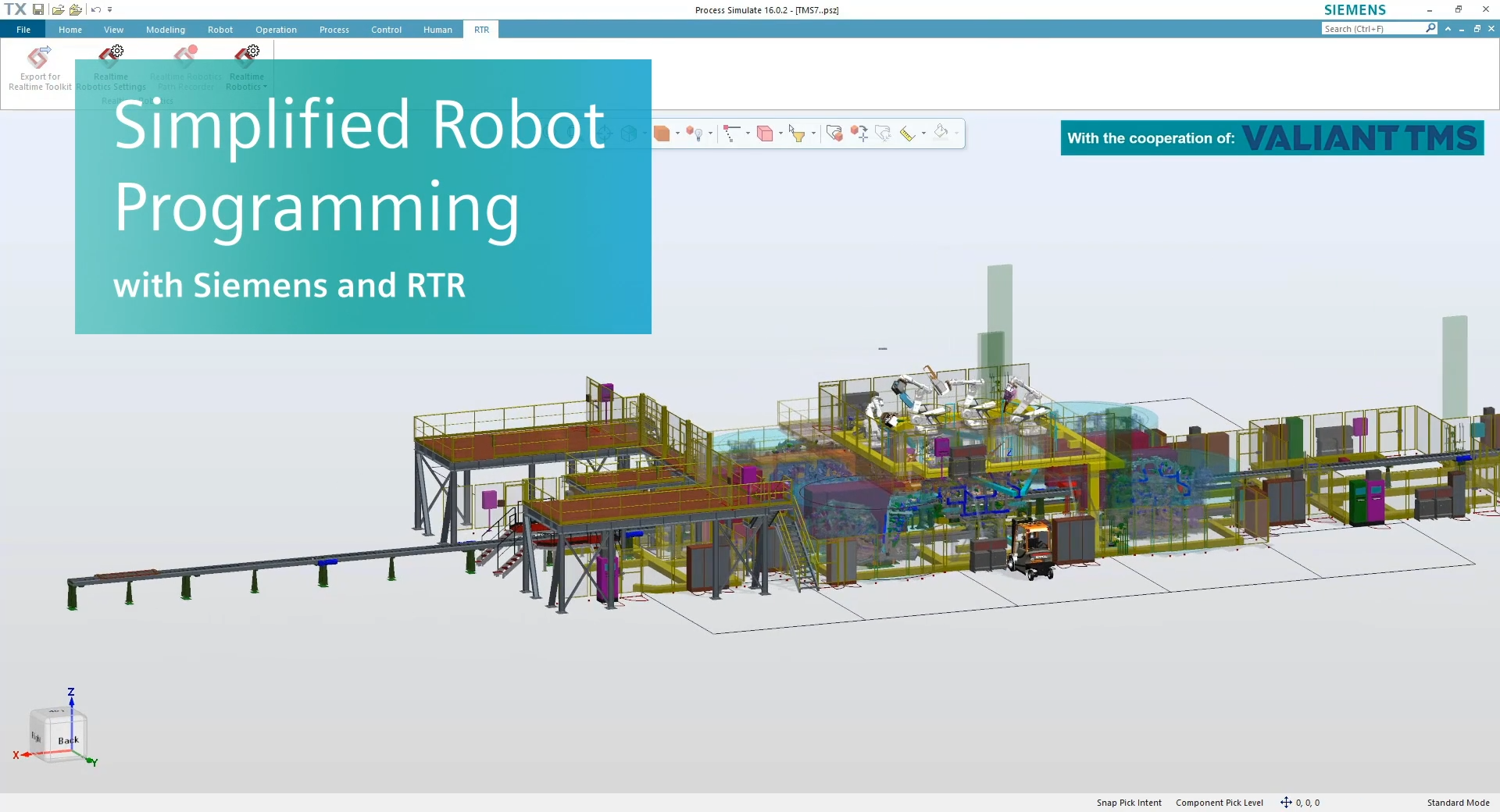

Valiant TMS shows benefits of Siemens and Realtime Robotics partnership

Recent proof of concept with a global automotive line builder shows significant savings in the engineering time required to program multi-robot systems.

Valiant TMS participated in a proof of concept with Siemens Digital Industries Software and Realtime Robotics (RTR) which showed that RTR’s technology seamlessly integrated into Tecnomatix Process Simulate software simplifies robot programming and interlocking by automating motion planning. The combined technology enables manufacturers and integrators to easily program, simulate and validate multi-robot systems, significantly reducing engineering time.

For the proof of concept, TMS provided a recent engineering study for an automotive body construction framing station. TMS provided KPIs like the required cycle time and the required time it takes today to program the robots. In this case, it takes 90 hours of programming for the 7 robots selected to produce the 60 weld spots required. Framing station fixtures and robot end-of-arm tooling is complex and the robots need to work in a very tight space.

“The combination of Process Simulate with Realtime Robotics improves our efficiency, reducing our offline programming efforts by more than 80%.”

It took only 15 hours to create the required robot roadmaps and to demonstrate collision-free robot motions and on-the-fly interlocking to TMS while achieving the required cycle time. This shows a reduction in programming effort of more than 80% in comparison to the typical required engineering time.

“The combination of Process Simulate with Realtime Robotics’ automated motion planning and interlocking has provided a significant improvement to our efficiency, reducing our offline programming efforts by more than 80%”, says Michael Schaubmayr, Group Manager Mechanical Engineering Simulation, TMS Turnkey Manufacturing Solutions GmbH. “This presents to us a tangible and strategic advantage in the industry.”

Additional optimizations can be achieved by trying different design options since reprogramming the robots to test an alternative is almost cost-free. All that is required is to set the target points for the robots in Process Simulate and, while running the simulation, allow the Realtime Robotics controller to automatically calculate the required motions and interlocks.