The future of bridging humans, robots, and humanoids with Process Simulate software [VIDEO]

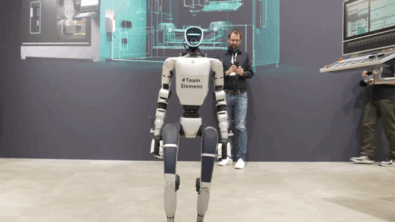

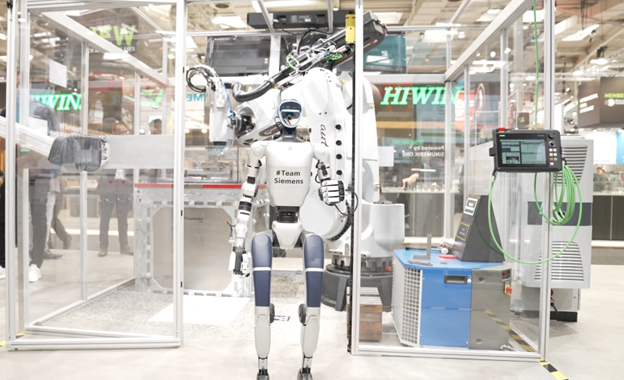

The manufacturing industry is entering a new era where humanoid robots are expected to gradually enter the factory floor within the next few years. Unlike traditional industrial robots with rigid, pre-defined configurations, humanoids are designed in the shape of the human body and can replicate their motions and capabilities. This design is intended for them to function in environments originally built for people, enabling them to use existing tools, equipment, and workstations without extensive modifications to the production floor.

The market outlook underscores humanoid robots in manufacturing and their potential. According to Fortune Business Insights, “The global humanoid robot market size was valued at USD 2.43 billion in 2023 and is projected to grow from USD 3.28 billion in 2024 to reach USD 66.0 billion by 2032, exhibiting a CAGR of 45.5% during the forecast period. Asia Pacific dominated the humanoid robot market with a market share of 41.97% in 2023.”

For manufacturers, this positions humanoids as a new class of professional service robots that can seamlessly integrate with humans, cobots, and other automation systems — ultimately boosting both productivity and flexibility. With that said, humanoid robots still remain in a highly researched market and aim to perform repetitive assembly line tasks in a dynamically changing environment. These advances are powered by accelerated research invested in sophisticated AI capabilities, which will eventually help enable humanoid robots to perceive their surroundings, make task-level decisions, and autonomously execute complex, multi-step processes.

However, their ability to rapidly learn and adapt makes them particularly exciting — but also introduces new levels of uncertainty for manufacturers. This is where Siemens advanced manufacturing simulation and validation software, Process Simulate, becomes indispensable, allowing manufacturers to virtually model and simulate the entire ecosystem — humans, robots, and automation systems — and eventually humanoids, within a unified production environment. By doing so, it provides the ability to address integration challenges early, validate feasibility, optimize workflows, prevent resource conflicts, and confirm that production lines can achieve their required cycle times before deployment on the shop floor.

Now, let’s look into the future and explore how Process Simulate Human could be a critical solution for de-risking the integration of humanoids into modern manufacturing.

Please note this demonstration is a proof of concept.

From Simulation to Application: Humanoids on the Factory Floor with Process Simulate Human

Industries like automakers are testing humanoid robots for tasks such as handling sheet metal, delivering materials, and performing inspections. The main advantage: they can operate in human-designed spaces without costly facility redesigns. Humanoids could eventually address labor gaps in repetitive, low-skill, or physically demanding work, while offering the flexibility of a human form combined with robotic precision. By enabling manufacturers to model, simulate, and validate the production floor, the software helps anticipate and address integration issues while confirming the feasibility and efficiency of the planned production line. Interesting in exploring? Launch the Process Simulate X Human cloud-based trial today.

“The introduction of humanoids into manufacturing environments brings substantial integration complexity. These robots will need to work seamlessly alongside traditional industrial robots, cobots, AMRs, conveyors, and human operators. While this mix can pose significant integration challenges, it is precisely here that Process Simulate software would shine.”

– Article author, Alex Greenberg, Director of Robotics 4.0 Simulation, Siemens Digital Industries Software

To successfully integrate humanoids, manufacturing simulation tools like Process Simulate Human will be essential. Here’s how manufacturers could leverage its capabilities:

- Cycle Time Analysis

Estimate task durations, accounting for humanoid walking speed, reach, and handling times. - Workstation Validation

Verify tool and bin placement against humanoid ranges of motion to ensure ergonomic and feasible task execution. - Path & Collision Planning

Simulate humanoid movement and robot interactions to optimize layouts, reduce bottlenecks, and prevent interference. - Resource Assignment

Use a humanoid library to match the right robot to each job based on capability and physical constraints. - Human-Robot Collaboration

Validate shared task scenarios to ensure clarity, safety, and efficiency where humans and humanoids work together. - Downtime Management

Considers charging station placement and recharge cycles to accurately reflect humanoid availability in production planning.

By modeling humanoids within Process Simulate Human such as demonstrated in the proof of concept video, manufacturers could test feasibility, validate ergonomics, plan workflows, and de-risk integration before deployment, ensuring these rapidly evolving robots fit seamlessly into complex production environments.

This demonstration highlights the emerging possibilities of integrating humanoids within Process Simulate to enhance industrial simulation. Over time, humanoids could become standard labor units — just like industrial robots are today — making simulation a crucial step in managing both benefits and challenges. Although still a point of concept, it signals the direction of future innovation.

Comments

Leave a Reply

You must be logged in to post a comment.

nice