Synthetic Data Generation: Computer Vision Powered by AI

Siemens SynthAI revolutionizes vision-based automation systems

Artificial Intelligence (AI) and machine learning (ML) continue to play a vital role in accelerating digitalization and impacting the future of manufacturing. Greater efficiencies, lower costs, improved quality, and reduced downtime are just some of the potential benefits of embracing AI and ML. It involves using technology to automate complex tasks and revealing previous unknown patterns in manufacturing processes or workflows.

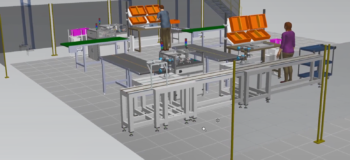

One of the latest trends in the artificial intelligence domain is utilizing synthetic data, which is produced from computer simulations or algorithms, providing a cost-effective substitute to real-world data that’s becoming commonly used to create accurate AI models. Specifically, synthetic data and AI for computer vision, which can be used in conjunction with Siemens digital twin technology. Manufacturers can accelerate validation for machine-based vision powered by AI for robotics and other systems, which in return, creates major cost and time savings for manufacturers to solve complex challenges in advance before commissioning a physical robotics system.

For assembly, quality control, movement, or other assigned tasks a robotic system must perform, it must rely on AI to recognize the required object or filter through long training and large quantities of visual data. AI platforms typically need large groups of data to build decision making algorithms, and that data must meet the standards for having both quantity and quality. However, gathering visual data for traditional machine learning can be labor-intensive, expensive and an overall cumbersome process to monitor and manage. To broaden the use of synthetic data and AI for computer vision beyond the use of experts and to make it a less laborious task, there needs to be a quick and easy solution that allows manufacturers to achieve high-impact results within just a few hours.

Now, manufacturers like you can automate machine learning training for vision systems. As an organization that already has a deep commitment to simulation and transforming our customer’s path to digitalization through Siemens software solutions such as Tecnomatix Process Simulate, NX for Manufacturing, and much more, we continue to explore the unchartered territories for AI in manufacturing by revealing how Siemens cloud-connected software and IoT-enabled hardware brings the possibilities of tomorrow to our customers today.

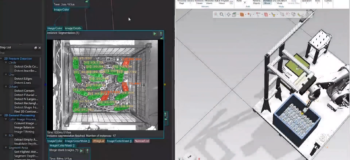

“We were looking for a quick and easy solution that will enable us to detect wire terminals in a robotic electric cabinet assembly station. With SynthAI, our control engineers were able to achieve great results within just a few hours.”

Omer Einav, CEO, Polygon Technologies

Our existing software already generates different flavors of “what if” simulation scenarios for manufacturing engineers to verify but combine these scenarios with computer vision powered by AI and we equip machines efficiently with the right data to make decisions on their own. That is why Siemens built the cloud-based platform, SynthAI, to improve the ability to generate high-quality, synthetic images and trained models. Rather than waiting for preproduction parts to be ready or using complex processes to generate synthetic data, machine vision specialists only need to provide the part’s 3D CAD data to SynthAI.

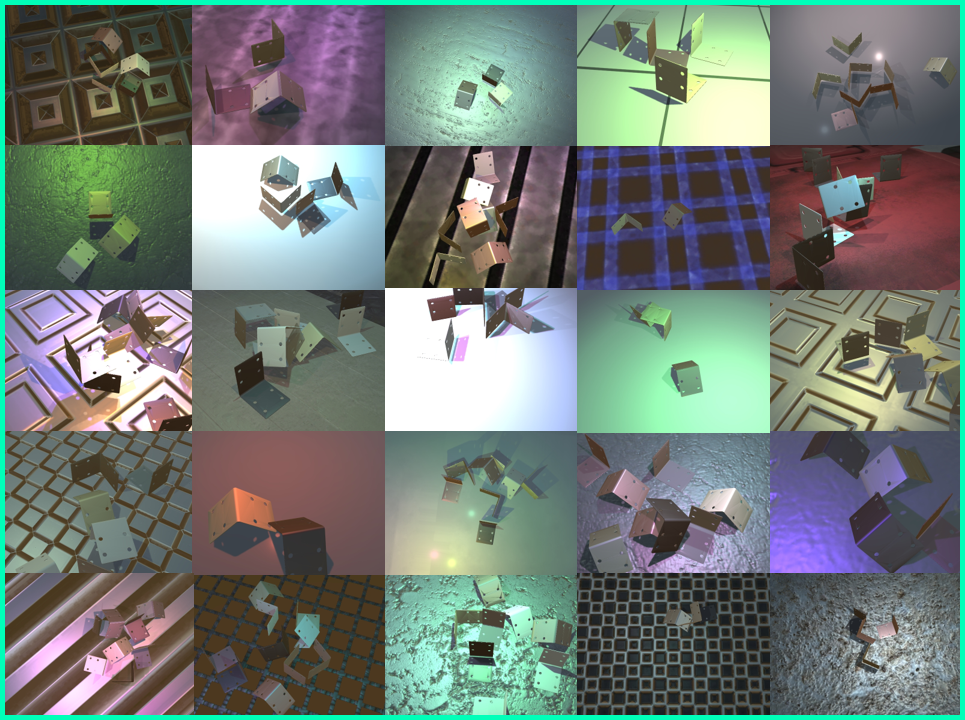

The cloud-connected solution removes the complexity typically associated with the data-driven method and is a comprehensive way to generate quality synthetic data. The first step is uploading a CAD model into the SynthAI platform, then the software generates thousands of images with randomized parameters in minutes. Synthetic data for training AI isn’t an entirely new concept but removing the cumbersome image generation and annotation stages from the vision system training is a new approach. That way, synthetic data can start training the system almost as quickly as the system can be designed, freeing up valuable time and cost savings for manufacturing engineers.

Stay tuned for how Siemens is taking its depth of knowledge in both product engineering systems as well as production preparation and defining a new path to digitalization for our customers.

Request SynthAI Early Access

Use synthetic data to accelerate machine learning quickly and easily for vision-based automation systems.