Simulation without limits: bringing AI, Digital Twin, and Copilots to the Factory Floor

Today, manufacturing simulation is being reimagined – thanks to AI-powered copilots, low-code interfaces, and seamless connectivity to real production data. Simulation is increasingly being used by more people, more often, and at more points in the manufacturing lifecycle.

Manufacturers are being pushed to do more with less — reduce downtime, cut energy costs, improve productivity, and empower a workforce in flux. The key to doing all this efficiently? That’s where AI-powered simulation and digital twin technology is helping boost manufacturer’s transformation faster than ever before.

Senior Director Portfolio Development

Siemens Digital Industries Software

In a recent webinar hosted by leading industry publication Automation World, Uli Rossgoderer, Senior Director of Portfolio Development for the Tecnomatix portfolio, joined the discussion to discuss how manufacturing simulation technologies are becoming more intelligent, accessible, and impactful across the manufacturing floor.

Here’s a closer look at the key insights — and why you should watch the full session:

The big shift in modern manufacturing

Modern manufacturing is undergoing a major transformation. With AI copilots, cloud-powered low-code interfaces, and real-time data integration, simulation is no longer limited to experts. Manufacturers can now optimize processes faster, with fewer resources, and empower a broader range of users — even those without deep technical expertise.

As Uli explained, Siemens isn’t just enhancing simulation tools — it’s democratizing them. AI-powered interfaces are making complex capabilities more accessible and intuitive, enabling more teams to drive value from simulation, whether in robotics, production planning, discrete event modeling, or ergonomic analysis.

Robotic Simulation

Another area seeing massive transformation is robotics simulation. Siemens is making these once-complex tools more approachable, even for smaller manufacturers.

“We’re making robotic simulation more accessible. With software-as-a-service and simplified interfaces, even small manufacturers can simulate robotic cells without disrupting production.”

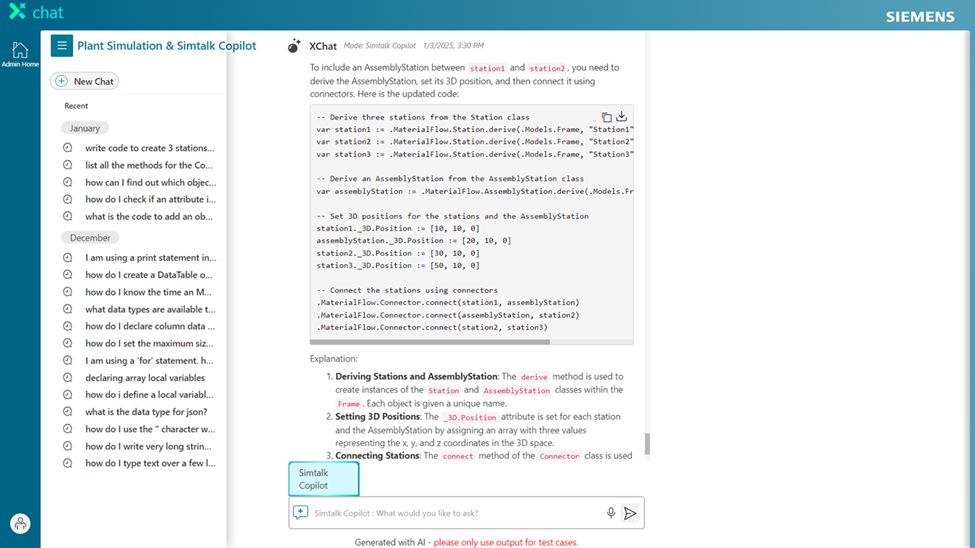

Simulation Copilots: Smarter, Not Harder

A major enabler of this shift is Siemens investment in AI copilots for simulation. These copilots assist users in generating simulation logic, interpreting results, and even suggesting actions — all through natural language interfaces. Readily available in Process Simulate, the Copilot plays a critical role in minimizing production downtime with advanced AI-powered troubleshooting. Imagine instantly diagnosing issues in complex robotic simulations—without manual effort. By delivering fast, automated debugging, Copilot transforms problem-solving into an intuitive, precise process. And it doesn’t stop at detection—it recommends practical solutions, such as optimizing robot cycle times, empowering engineers to accelerate production and improve overall efficiency.

Uli also touches on the development plans for Plant Simulation and SimTalk and what this means for users. For example, we’re making it simpler for SimTalk novice users. Simply describe the process you want to simulate: “Model a buffer with limited capacity,” or “Add a shift schedule to this station”—and the Copilot is there to help. It leverages documentation sources to suggest lines of codes and going forward will help to suggest improvements.

For example, in Plant Simulation, we want it to make easier for users to use SimTalk. They just describe what they want to simulate — and the copilot helps generate the model or fix errors,” says Uli.

Whether you’re troubleshooting a simulation or building a factory model from scratch, the Copilot turns natural language into executable logic — accelerating development, reducing errors, and opening simulation to a broader range of users.

Ergonomics Simulation: Insights from a Simple Photo Upload

Another area where AI-powered simulation is making waves is in ergonomics. Uli shared how Siemens is simplifying workplace safety assessments using AI-powered ergonomic analysis:

“Users can upload a photo of a worker at a station. Our simulation powered with AI matches it to a virtual model and runs a full ergonomic assessment — instantly flagging risk factors.”

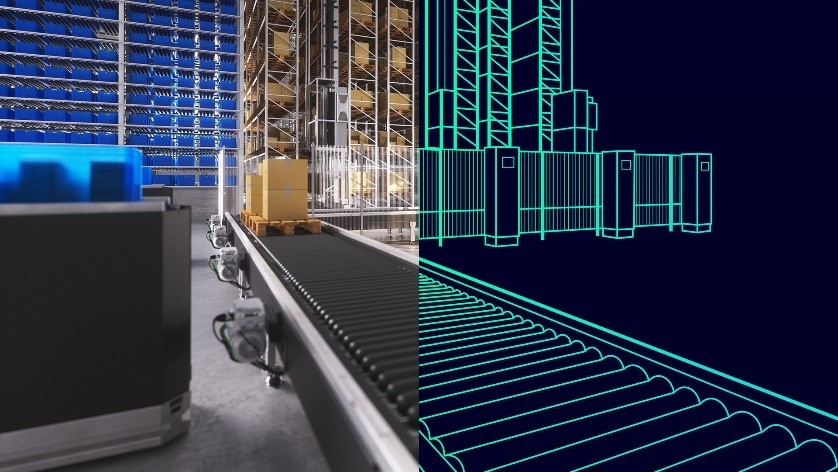

Breaking Down Barriers to Scale and Cloud-Based Simulation

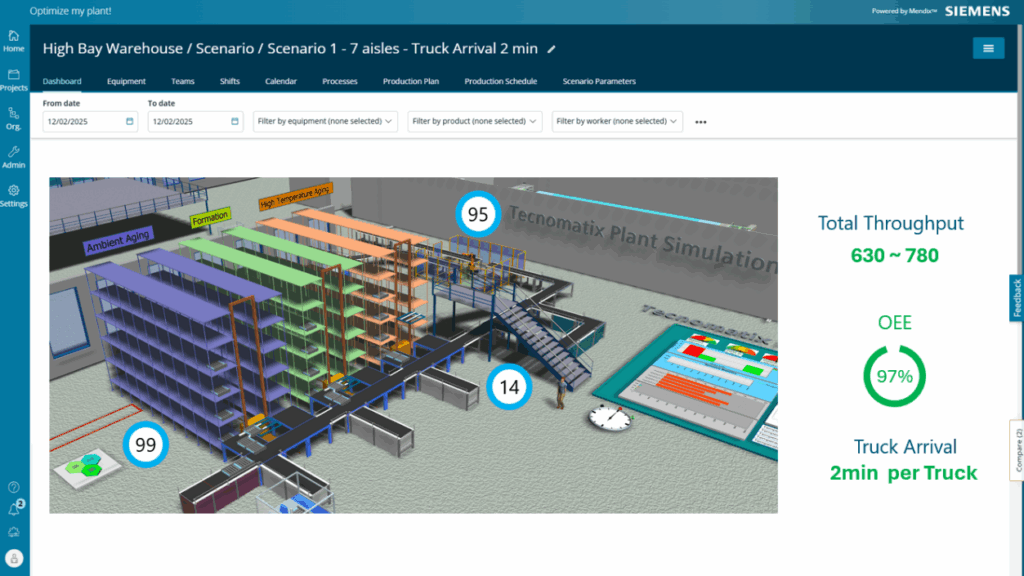

While engineers thrive with complex models, shift leaders and production managers need something more intuitive. Uli pointed to Optimize My Plant, a Siemens application that wraps simulation models in a low-code user interface, enabling line managers to run “what-if” scenarios independently. Optimize my plant solves this with a user-friendly interface that provides real-time KPIs, enabling all levels of the organization to act on data rather than gut feel.

“We’re bringing simulation closer to daily operations. This lets non-experts interact with complex models and make smarter decisions — without calling in a simulation expert every time.”

What’s Next? Autonomous AI & Human-Robot Interaction

Looking ahead, Uli predicts major leaps in autonomous AI agents, humanoids, robot integration, and simulation-guided decision-making.

“The next step is not just generating insights, but taking action. Copilots will suggest changes — and eventually implement them.”

He also pointed to the growing role of situational awareness for robotics — where robots use simulation and AI to make decisions in real time, based on camera input or environmental sensors.

These highlights just scratch the surface. In the full session, Uli explores:

- Real-world success stories from manufacturers using AI-powered simulation

- How companies are reducing downtime and energy use with Siemens manufacturing simulation software

- The role of simulation in bridging workforce skills gaps

Explore how Siemens is helping manufacturers rethink production with smarter simulations, robotic modeling, and cloud-powered collaboration.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)