Siemens Intosite – Go Digital, Go Visual

This article was written by Joe Barkai, a recognized industry analyst, strategy adviser, blogger, and published author. His focus is on researching, forecasting, and the strategic application of technology to drive innovation and competitiveness.

The article was originally published on JoeBarkai.com/blog.

Fueled by ubiquitous connectivity, cloud-stored data lakes and artificial intelligence-based analytics, Industry 4.0 promises to create smart factories in which interconnected manufacturing systems communicate, in real time, with production machinery, robots and human operators throughout the entire value chain.

The digitalization and automation of factory floors and supply chains give manufacturing organizations an unprecedented insight into their manufacturing operations and product performance. Rich information from plant floor equipment and advanced analytic tools help manufacturers optimize manufacturing operations and improve manufacturing capacity, yield and quality. And as manufacturing companies in the industrial world continue to battle a growing shortage of skilled workforce, pervasive digitalization and advanced optimization help streamline operations and maximize efficiency and resource utilization.

This is the promise of Industry 4.0, and forward-looking manufacturers, line builders and equipment vendors are embarking on aggressive and innovative transformational strategies to build highly efficient plants, assembly lines and manufacturing machinery.

Accelerating Adoption

Manufacturing environment is becoming more global at an increasingly faster rate. Manufacturers are looking to exploit new markets for their products and set up distributed manufacturing networks to be closer to the customer and to leverage preferential labor rates and tax policies. These plants form diverse networked communities of manufacturing and quality engineers, machine operators and maintainers and supply chain and logistics experts that must work collaboratively across many time zones and around the clock.

Digital Twins of Production Facilities

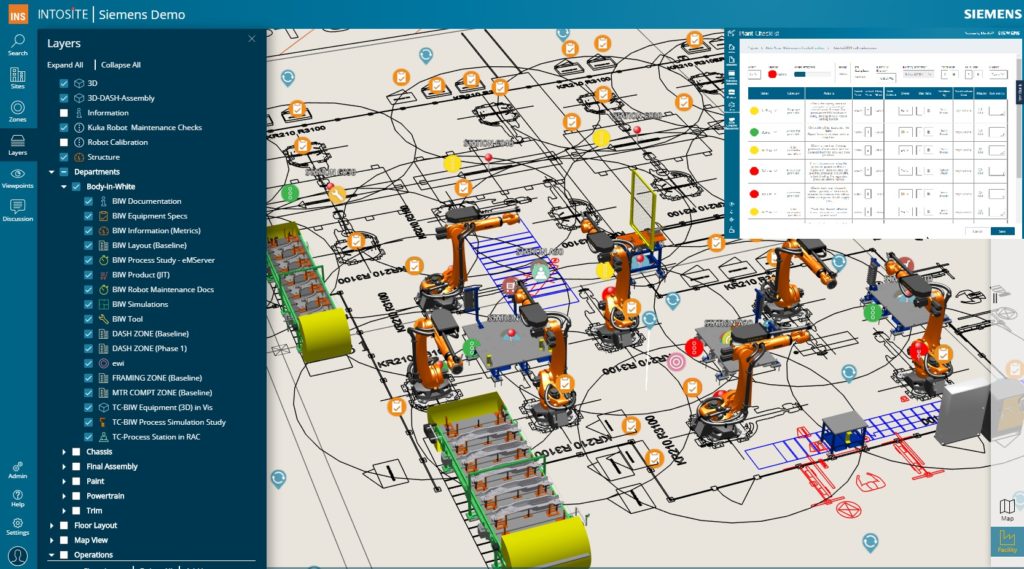

A digital twin is a virtual replica—a digital model of some sort, such as a three-dimensional geometric model—of a physical asset. In Industry 4.0 manufacturing, the digital twin is a complete virtualized plant comprises any number of digital representations of the shop floor and manufacturing equipment and the flow of raw materials and work in progress. The digital twin represents a dynamic digital profile of current operation characteristics as well as an analytical and historical track record of the manufacturing plant.

These digital representations are not merely a collection of individual tools such as CAD and MES or data repositories such as MES Historians and job tickets. In a digital twin, these objects are tightly integrated with each other via the organization’s digital thread and connected to instrumented physical assets to form a cyber-physical system that represents the entire plant and running processes in real time, and facilitates monitoring, analysis and optimization of complex integrated operations.

Read the complete article, “Siemens Intosite – Go Digital, Go Visual,” at JoeBarkai.com.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)