Siemens featured in sustainable manufacturing story

Siemens PLM was recently featured prominently in “Sustainable Manufacturing: There Are Apps for That,” by Lawrence S. Gould, contributing editor for Automotive Design & Production magazine. The story, about “software that supports sustainable manufacturing and environmentally conscious products to help make going green somewhat easier,” highlights examples of database management and presentation, CAE and simulation software.

Sustainability outside the factory.

Siemens PLM’s Teamcenter is described as a system to collect all compliance data in a central repository within an enterprise and automate the supplier material and substance disclosure (MSD) process and manage materials and substances as components of the product definition. The article goes on to say that Teamcenter has an integration component to the International Materials Data System (IMDS), a database maintained by Hewlett-Packard. The Teamcenter-IMDS integration automatically synchronizes updated material data sheets in IMDS to a company’s design/engineering systems, and vice versa. The article then describes how the Teamcenter-IMDS integration helps sustainable product design.

When it comes to sustainability outside the factory, Kerri Doyle, Siemens PLM Teamcenter product marketing manager stated that, sure, there are “niche products out there to address sustainable manufacturing but they are on their own little islands, their own silos. We feel they’re not as good if they’re not tied together with the BOM” – and the rest of the information needed for product development. Kerri goes on to say that not so incidentally, companies can “meet the requirements of regulatory and industry compliance using the same PLM environment used to accelerate product development.”

Sustainability inside the factory.

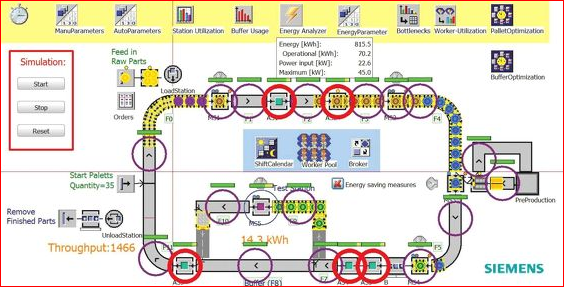

When it comes to actually manufacturing products, “you have to make sure the machines and resources you’re using are energy optimized,” says Abhijit Dastidar, senior manager, automotive & transportation industry marketing, for Siemens PLM. Siemens PLM Tecnomatix software uses simulation to predict the energy utilization of a factory. “We are not creating a different sustainable manufacturing domain. Sustainability is part of the product lifecycle development. The primary function of plant simulation is to optimize your throughput – and that’s what Tecnomatix simulates. But you not only want to optimize your throughput, you want to analyze the energy utilization.”

Siemens PLM had the last say in the story. “The goal, concludes Doyle, is to focus on sustainability “way up front in the design cycle versus later on,” when non-compliance is “riskier” because the costs in design changes, fines, even lost sales, are so much more significant.”

View the entire story online at Automotive Design & Production and let us know what you think in the comment section below.