Leading automation machinery manufacturer improves safety with Process Simulate Safety Robots Manager

Hear from Ondřej Pažout, Benthor head of robotics and simulation, about how the leading automation machinery innovator uses Siemens Process Simulate software to help elevate robotic safety and efficiency. Benthor is a leading innovator in the manufacturing industry, specializing in the design and integration of advanced robotic systems.

Automation solutions for machines and production facilities

Benthor Automation, based in Mladá Boleslav, Czech Republic, develops automation and information technology (IT) systems for industrial manufacturing. The company’s customers are primarily in the automotive industry and include domestic and foreign car makers. Benthor’s core competencies include automation solutions for machines and production facilities with superior control technology and material flow management, and it offers services throughout the process chain, including consulting, technical solutions, hardware planning, software development, system deployment and after-sales service.

At Benthor, we prioritize the safety of robotic systems, and thanks to our collaboration with safety experts, we are able to design cutting-edge manufacturing equipment with integrated safety elements from the very first concepts of the workstations. This way, we provide our customers with transparency — visualizing the future workstation while eliminating additional costs caused by misinterpretation or misunderstanding of functionality.”

Ondřej Pažout, Head of robotics and simulation for Benthor automation s.r.o.

In the industrial automation space and as robotic systems become more prevalent in densely populated automated lines, functional safety remains crucial to prevent human injury and equipment damage. When planning a new robot station or lines, whether implementing changes for new products or layout adjustments, prioritizing robot safety is paramount. The intricacies of addressing robot safety in production systems started only as a discussion between Benthor and Siemens team, and now it has evolved into a strategic business priority for Benthor. That is when the leading automation machinery manufacturer realized the value of using Process Simulate Safety Robots Manager to address the safety of robotic workstations.

Meet the robot safety experts part of this collaboration:

Head of robotics and simulation Benthor Automation

Product Manager Siemens Digital Industries Software

Director of Advanced Robotics Simulation

Siemens Digital Industries Software

Hear from Ondřej Pažout, Head of robotics and simulation for Benthor

Priority at Benthor

At Benthor, we fully recognize the crucial importance of safety in the integration of robotic systems. We design robotic workstations with the goal of minimizing risks for both operators and the equipment itself. Our integrations include not only physical barriers, but also sophisticated software tools for simulation and safety management. We address safety right from the start of the project by using simulations that consider all possible scenarios and potential safety incidents arising from risk analysis.

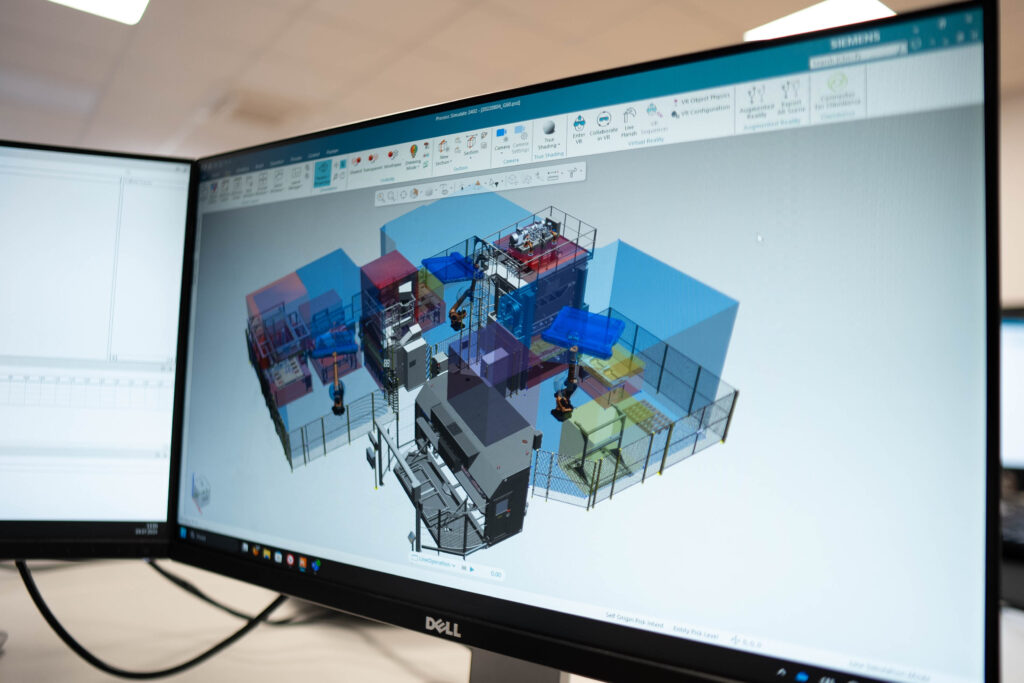

This approach allows us to eliminate potential risks even before the construction of the workstation begins. This helps us avoid costly adjustments to equipment or software during or after deployment. Thanks to our collaboration with the Siemens team responsible for Tecnomatix Process Simulate Safety Robots Manager, Benthor is able to implement advanced simulation technologies and methodologies that ensure detailed analysis and optimization of robotic workstations.

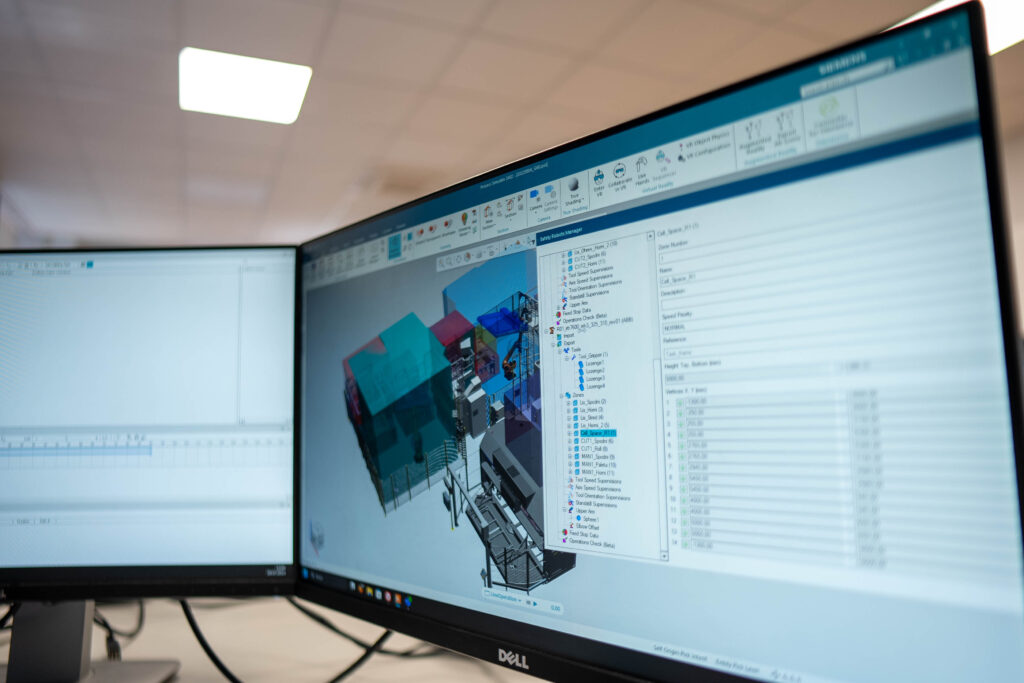

Solution: Process Simulate Safety Robots Manager

One of the key tools we use at Benthor is Process Simulate Safety Robots Manager (SRM). This application enables detailed management of robot safety functions and helps us simulate safety scenarios before physical implementation. With SRM, we can set up safety zones, define allowed movements, and monitor the status of robots in a simulated environment where there is no risk of injury or hardware damage. This allows us to quickly respond to any safety deviations and take appropriate measures during the design or virtual commissioning phase. This approach not only increases safety but also the efficiency, reliability, and profitability of automated systems.

Robot safety use cases

By utilizing solutions from the Tecnomatix Process Simulate portfolio, we have integrated more than 2,000 robots at Benthor, with nearly half of the installations using Safety Robots Manager to simulate safe robot behavior at the software level. Recently, we successfully implemented a robotic system project for the production of interior textile linings in the automotive industry. The core focus was the safety of operators when handling materials and preventing collisions with pressing tools. This resulted in more than 40 safety zones were successfully deployed and simulated across three robots. Thanks to simulation with SRM, Benthor was able to optimize robot movements and the production cycle without compromising safety standards.

Ondřej Pažout, Head of robotics and simulation for Benthor automation s.r.o.

A robust partnership and the future of robot safety

The collaboration between Benthor and Siemens has proven invaluable in advancing the safety and effectiveness of our robotic workstations. By leveraging advanced simulation tools like Process Simulate Safety Robots Manager, Benthor continues to innovate and ensure that its systems meet the highest safety standards. Looking ahead, Siemens and Benthor are excited about future projects and the ongoing improvement of advancing safety protocols, which will further strengthen Benthor’s commitment to providing next-level solutions for its customers.