Interview with Zvi Feuer – Part 4: Growing the business – moving the cheese

This is the 4th in our blog series featuring comments by Zvi Feuer about our agile processes.

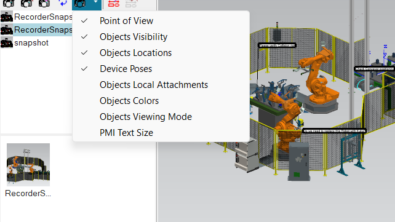

Moving into 8 domains of innovation

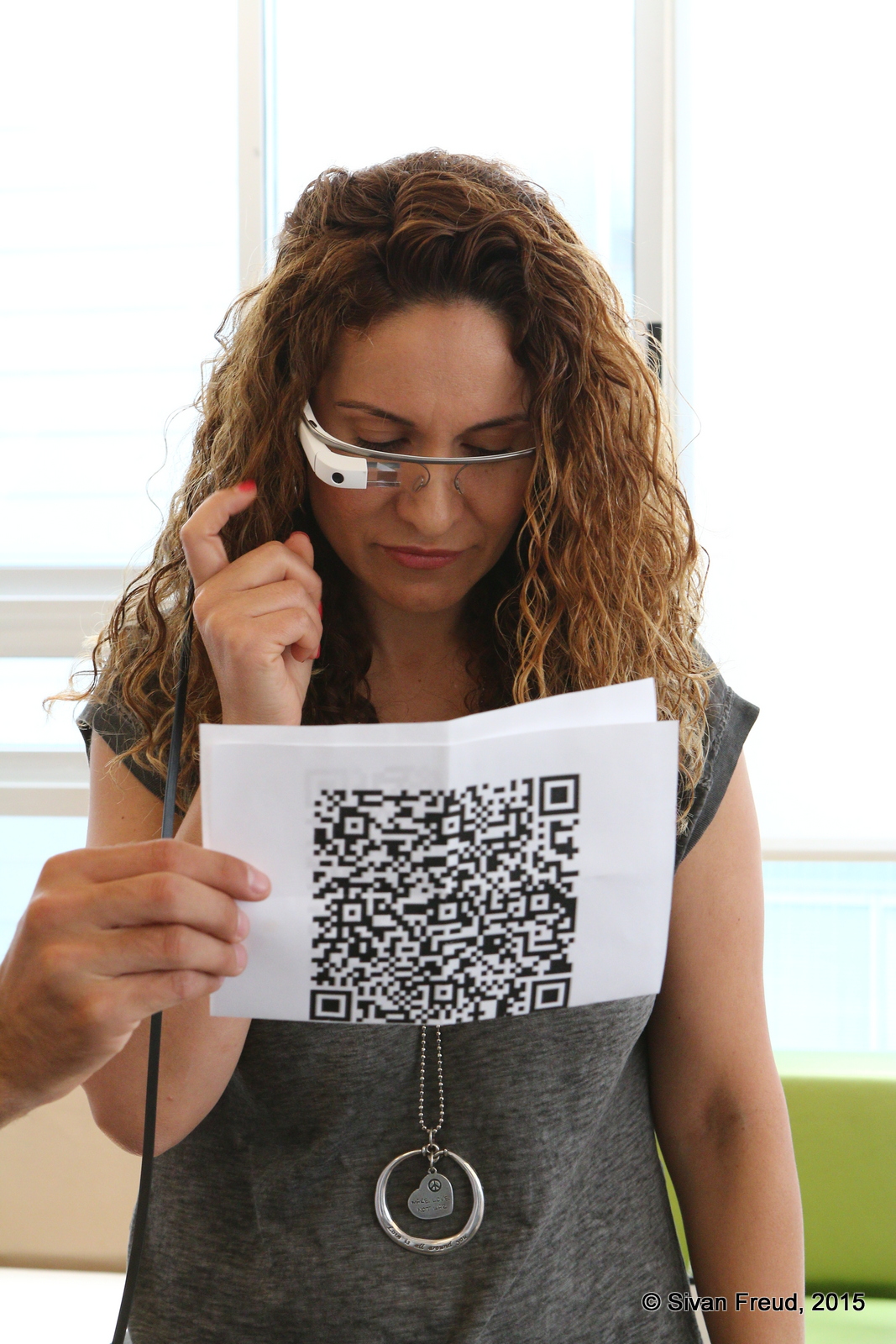

There are seven/eight domains of innovation that we’ve defined: Additive manufacturing, IoT, Big data analytics, Artificial Intelligence (AI), Augmented Reality/Virtual Reality, Cloud, Manufacturing collaboration, and Advanced Robotics. All of them are somehow connected. I’m happy to say that in each of these domains we have something going. In Additive we have a series of products, and we’re doing work in Advanced Robotics. I thought we’d do something in AI in our products, but we’re still not there. But we are using AI to focus on bugs we need to fix and this enables us to extract extra value for the customer. So we have been using some of these domains for creating very innovative projects, while others are helping us to work in new ways.

To move towards innovation, we’ve had to overcome people’s inborn resistance, like ‘who moved my cheese?’ It’s hard for them to give up what they are used to and are comfortable with. We had to work to show people the value in this change. They were like tourists on a bus – they come to a new place, hop off, hop on, and they go back to the same seat every time. But now the organization is in a completely different place – I don’t know if you feel it, but I do! The atmosphere in the corridors, the speed, the partnership for success.

We’re also doing ‘cross-section’ interviews, each time with 3 or 4 employees. They come to my office and I hear what they have to say. I get an impression of their reactions, what problems they see and I hear their insights and comments. We’re trying to take care of these things. The people are chosen completely at random – it’s called ‘talk to the boss’. There are people who don’t normally open up and talk to me in the hallway, at the townhalls or at the monthly Thursday breakfasts. We’ve brought in a lot of new people to work here. So I want to see how they are relating to things, and I see ongoing improvement.

We’ve grown the business by 25 percent. We have passed the $250 million mark! When I started over 5 years ago, it was about half of that. The results speak for themselves, but we shouldn’t let that confuse us – it’s not only because of us. It’s a combination of what we do and the sales. We had to do a lot of work to convince the sales people that it’s safe to go with us, to sell our products, because we will deliver. When we make a commitment, it’s a commitment, and when we promise something, we keep our promise. If the customer feels that he fails because we did not release everything he asked for – obviously, that’s not going to be good for our business. We work hard every day to complete what we promised the customer. If there’s a bug, we fix it, and if there’s an enhancement request which we feel is important, we will do it. All of this changed the way that people relate to us. Sales people are not afraid to talk about manufacturing and to sell our products – it’s now part of the mainstream. And they don’t report on it in a separate manner anymore, which is good. Now we are part of the PLM product spectrum.

About the author

Zvi Feuer is senior vice president of Manufacturing Engineering Software for Siemens PLM Software, a business unit of the Siemens Digital Factory Division. He has more than 25 years of experience in Enterprise Software business management, with a primary focus in the Manufacturing Industries. He has worked for: the Israeli Aircraft Industries (IAI); Digital Equipment, a leading provider of hardware and system integration projects; and since 1995, with Tecnomatix, UGS and Siemens. Feuer’s current responsibilities include leading global teams and initiatives to develop and service customers worldwide and providing Manufacturing Engineering Software solutions. These solutions include optimizing production and service facilities, assembly line design, developing and validating production systems and programming CNC machines in major machine shops. Feuer received his Master of Science in industrial engineering from Technion – Israel Institute of Technology, and also received an executive MBA from UCLA – NUS.