How Roller Hemming and Arc Welding Applications Change the Way We Program Robots

Challenges in Modeling Continuous Processes

In modern manufacturing, many processes are continuous by nature. Roller Hemming, Arc Welding, 3D printing, and similar operations rely on long, smooth paths along the part to achieve consistent quality, repeatability, and efficiency.

However, in many simulation and robot programming tools today, these processes are still represented as a series of small, disconnected tools. Engineers are often required to split a single physical operation into many individual actions to handle reach limits, collisions, singularities, and transitions.

This creates real overhead for experienced users. Programming takes longer, updates become harder to manage, and even small design changes can lead to significant rework. More importantly, the digital model no longer reflects how the process actually runs on the shop floor.

For less experienced users, the challenge is even greater. Defining and maintaining such fragmented operations is error-prone and often requires multiple review and correction cycles by more experienced peers.

This raises a fundamental question for the industry:

Can we define, manage, and optimize a long and complex path as a single Continuous Operation, while letting the system handle the underlying complexity for us?

Continuous Operations in Process Simulate: A New Approach

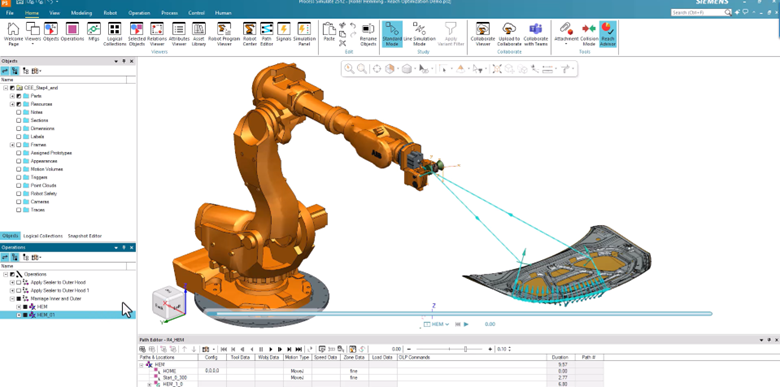

Process Simulate introduces a new approach to Continuous Operations that directly addresses this challenge.

Instead of managing a process as a fragmented sequence of actions, the operation is treated as a single, holistic entity. Geometry, strategy, motion behavior, air moves, OLP, external axes, and related definitions are all handled within a unified operation framework.

This approach enables:

- Holistic control of long and complex paths

- Automatic propagation of changes across the entire operation

- Reduced manual effort when handling kinematic limits or design updates

- Faster validation with higher confidence in the final result

- Planned capability to store operation settings as templates, allowing teams to reuse proven setups and leverage experience across future parts

To understand the impact, let’s look at two concrete examples: Roller Hemming and Arc Welding.

Roller Hemming Continuous Operation

Roller Hemming is a strong example of a process that benefits from a continuous representation. The new Roller Hemming operation allows engineers to define geometry, select strategies such as multi-pass folding, and immediately review the resulting continuous path in the simulation.

Changes to geometry or strategy are reflected instantly, providing fast feedback and simplifying validation. Instead of managing the process point by point, the operation is handled as a single continuous path.

The result is:

- Faster setup and iteration

- Fewer manual corrections when geometry or strategy changes

- A smooth, visually continuous hemming path that is easy to validate

Arc Welding Continuous Operation

The Arc Welding application allows users to define their engineering requirements directly in the application, and let the system generate the continuous welding path automatically.

Instead of manually building and managing individual weld moves, users specify what they need: the seam, nominal tool alignment, multi-pass definitions, skip welds, weaving patterns, and touch sensing locations. Based on these inputs, the system creates a complete continuous operation.

The result is an operation that is immediately visible and ready to validate. Engineers can review the path, run the simulation, and adjust parameters with confidence.

This approach simplifies arc welding programming, improves consistency, and significantly reduces setup and validation effort.

Looking Ahead: Expanding Continuous Operations

The Continuous Operations framework is designed to scale beyond the initial use cases. Several additional capabilities are already in development and will further extend this approach across manufacturing processes.

Examples include:

- Improved path optimization to better handle collisions, reachability, and singularities

- Enhanced support for external axes and coordinated multi-axis motion

- Continued improvements to preview capabilities, user experience, and graphics

- Reuse of Continuous Operation templates across similar parts and programs

- Expansion to additional continuous process types built on the same foundation

- Deeper integration with the Path Editor and validation tools

- Ongoing incorporation of customer feedback to stay aligned with real market needs

These upcoming capabilities will continue to close the gap between physical manufacturing processes and their digital representation.

Why This Matters

The ability to create, manage, and optimize Continuous Operations represents an important step forward in manufacturing simulation.

For engineers and organizations, this translates into:

- Shorter programming and validation cycles

- Reduced risk of errors during commissioning

- Better alignment between the digital model and the real process

- A scalable foundation for future automation capabilities

The new Roller Hemming and Arc Welding applications demonstrate the first phase of this evolution in Process Simulate. They show how continuous manufacturing processes can be modeled and managed as what they truly are: continuous, with the system handling the complexity behind the scenes.