Driving production flow and virtual commissioning with Plant Simulation & Process Simulate

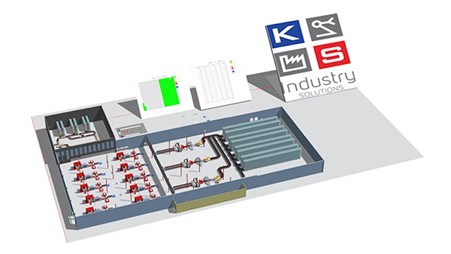

Digital twin technology can boost throughput by 15% and improve efficiency by 10–20% while reducing costs. KS Industry Solutions helps achieve this through Siemens Xcelerator digital solutions.

Imagine transforming your factory or production line without risky investments, endless trial and error, or costly mistakes. What if you could identify bottlenecks before they occur and visualize the entire operation in vivid detail, making improvements that boost efficiency and throughput, while also reducing costs? That’s the power of digital twin solutions, and its exactly what KS Industry Solutions is delivering as a certified Siemens partner.

KS Industry Solutions helps manufacturers of all sizes leap into digital transformation. Since 2011, they’ve partnered with Siemens Digital Industries Software, offering world-class tools like NX™ software, the Totally Integrated Automation (TIA) Portal, Teamcenter® software, Solid Edge® software and the Tecnomatix® portfolio.

Our mission is to empower manufacturers with digital twin technology that reduces risks and creates measurable business value.

Marcin Korzekwa, CEO, KS Industry Solutions

Facing Industry Challenges with Confidence

Investing in new production lines has always carried risk: bottlenecks can emerge, inefficiencies persist, and incorrect investment decisions can haunt a business for years. KS Industry Solutions understands that avoiding these pitfalls requires moving towards truly data-driven planning, robust simulation, and industry-specific know-how.

That’s why, as an expert Siemens partner, KS Industry Solutions leverages the powerful Siemens Xcelerator portfolio—NX, Plant Simulation, Solid Edge, Teamcenter, and Tecnomatix,unlocking transformative capabilities for industrial machinery, aerospace & defence, and automotive & transportation sectors.

The Digital Twin Advantage

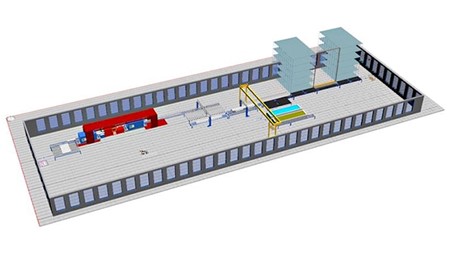

Think of a digital twin as a super-powered 3D model of your entire factory. It’s not just for looks—this virtual environment expertly simulates your operations. Want to know what happens if you tweak a production step, change materials, or re-route logistics? You can test it all in the digital twin before committing to real-world changes. Goodbye, guesswork!

With Tecnomatix Plant Simulation and Process Simulate, KS Industry Solutions helps clients virtually recreate their facilities. This digital playground enables manufacturers to:

- Spot and eliminate bottlenecks before they disrupt operations

- Increase overall production throughput by up to 15%

- Boost efficiency between 10 and 20%

- Reduce costs and commissioning risk

By using digital twin models, clients gain deep visibility into real-time and historical data, helping them plan, validate, and optimize everything from logistics to ergonomics.

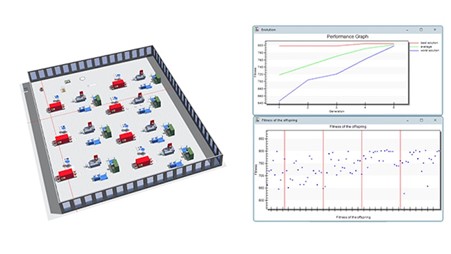

Proof-of-Concept Driven Transformation

One of KS Industry Solutions’ signature strengths is its proof-of-concept approach. Through tailored simulations and workshops, customers see early ROI—from reducing investment risk to validating new lines with virtual commissioning. With Plant Simulation, engineers model material flows and production systems, run genetic algorithm optimizations, and create custom simulation objects.

The outcome? Clients make informed decisions and head into full-scale implementation with confidence, knowing any new automation or upgrade will work smoothly.

Plant Simulation is not just a tool – it is a strategic enabler for smarter, safer and more efficient production

Grzegorz Traczyk, vice CEO and technical director at KS Industry Solutions

Combining Siemens Software for End-to-End Value

KS Industry Solutions delivers more than just simulation. NX CAD accelerates product design and reduces errors by up to 30%. NX Mechatronics Concept Designer enables early virtual commissioning, resolving integration and automation issues before they reach the shop floor. TIA Portal provides a unified engineering framework for swift automation programming and commissioning.

Their end-to-end expertise allows customers to:

- Shorten time-to-market and reduce implementation risk

- Remove integration headaches and speed up commissioning

- Improve operator safety and workplace ergonomics

For instance, an automotive supplier increased throughput by 15% and cut cycle times after KS Industry Solutions modelled and optimized a new production line. Another defence client used proof-of-concept digital twin and virtual commissioning to validate investments and lower project risk.

Results That Matter

On average, KS Industry Solutions’ customers see:

- Production efficiency improvement of 10–20%

- Investment risk reduced by 25–40%

- Implementation time cut by up to 30%

These measurable gains translate to faster projects, lower costs, and safer, higher-performing operations—a true testament to digital twin’s strategic value.

Empowering the Future with Siemens

KS Industry Solutions isn’t just delivering technology—they’re empowering manufacturers for the next era. Their partnership with Siemens means access to the latest in smart manufacturing methods and digital twin innovations. With customized training, hands-on support, and a commitment to results, KS Industry Solutions ensures that clients have the tools and expertise for sustainable transformation.

Ready to maximize your factory’s potential? Discover how KS Industry Solutions, together with Siemens software, can help you turn industrial challenges into opportunities for growth and performance.

Our mission is to empower manufacturers with digital twin technology that reduces risks and creates measurable business value

Marcin Korzekwa, CEO, KS Industry Solutions