Before Humanoids Hit the Factory Floor: Validating the Future with Manufacturing Simulation

Market trends suggest that humanoids will have the potential to become a significant work source in the manufacturing space within the next few years, helping to combat the workforce shortage many companies are already facing. The promise of a robot that embodies both the intelligence and form factor of a human is exciting and it is widely stated that the critical development period for humanoids will continue over the next two to five years. In fact, a simple search of humanoid-related patents reveals thousands of filings, led by China, the United States, and Japan. Furthermore, a comprehensive Morgan Stanley review noted that 73% of companies have confirmed their involvement with humanoids, reinforcing the momentum behind this technology.

Humanoid systems are inherently complex, requiring substantial investment not only in physical hardware but also in intelligence, the “brain” of the robot. Expertise in sensors, control systems, machine learning, AI, and natural language interaction are all essential to humanoid development. Just as importantly, deploying humanoids requires a deep understanding of their capabilities and limitations, much like how manufacturers today must carefully assess what humans and traditional industrial robots can — and cannot — do effectively.

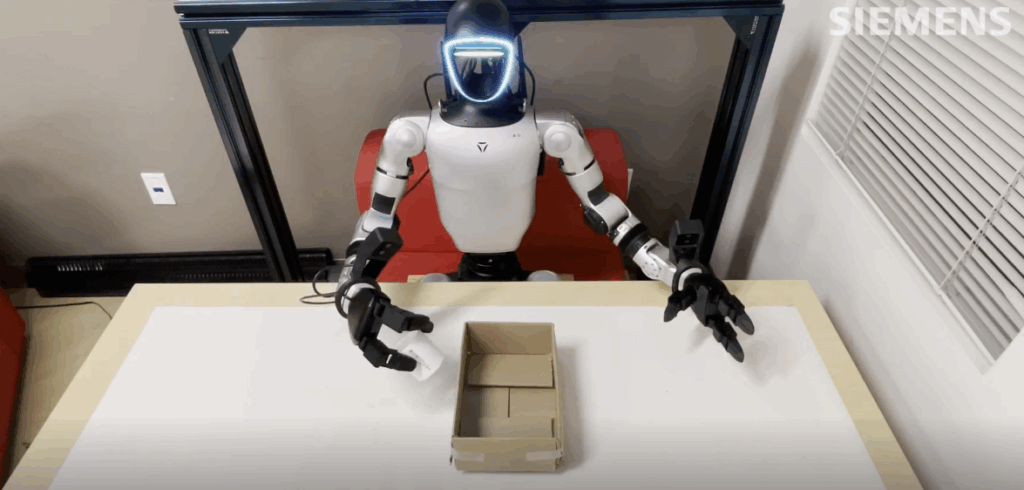

At Siemens, this understanding is built through high-fidelity simulation. Using tools such as Tecnomatix Process Simulate, Siemens software enables manufacturers to precisely model how manufacturing labor resources respond to task requirements. With strong competencies in advanced robotics and human simulation, Siemens solutions are uniquely positioned to model flexible manufacturing environments that blend automation, human workers, and emerging humanoid systems.

Meet the authors:

Siemens investment in humanoid and Autonomous Systems Research

Siemens leadership in this space extends well beyond software. At the research level, Siemens is actively investing in the foundations of humanoid and autonomous robotics through its Foundational Technologies organization. One example is Dr. Georg von Wichert, who heads the Autonomous Systems & Control research group at Siemens Foundational Technologies in Garching, Germany.

His work focuses on cognitive systems, sensor data fusion, autonomous machines, and the critical challenge of translating fundamental research into industrial reality, precisely the gap that humanoids must cross to become viable manufacturing resources.

In his recent thought leadership on bridging the gap between simulation and reality, Dr. von Wichert emphasizes that physical experimentation alone is too slow and too costly for modern robotics development. Training data is often scarce, and real-world testing carries safety and reliability risks. Robotics simulation, by contrast, enables engineers to prototype behaviors, validate designs, and explore “what-if” scenarios in a virtual environment before deploying a real robot. This approach accelerates iteration, improves repeatability, and significantly reduces risk.

This is where Siemens Software plays a direct role where Dr. von Wichert explicitly references Process Simulate as a key enabler for bridging simulation and reality, reinforcing the close partnership between Siemens research teams and its industrial software portfolio. The result is a continuous feedback loop between research, simulation, and deployment, a critical requirement for humanoids to transition from experimentation to production. Explore how Process Simulate could be a critical solution for de-risking the integration of humanoids into modern manufacturing in the demonstration below.

Towards human-centric and general-purpose robotics

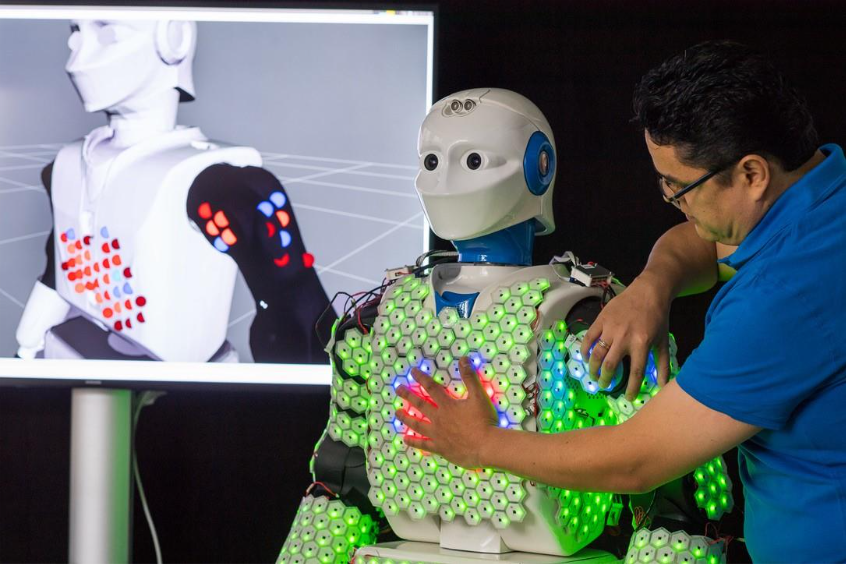

Achieving general-purpose humanoid capability requires more than precise motion planning. Robots must be able to recognize human intent, communicate naturally, and operate safely during purposeful contact, especially in environments such as factories, homes, and healthcare facilities.

Today’s humanoids still lack a robust mid-layer between high-level reasoning and low-level control. Robots can plan tasks and stabilize motions, but they struggle to translate intent into adaptable, reliable skills under real-world variability. While robot-native foundation models and advanced control approaches are emerging, they are not yet mature. Until then, specialized automation remains the most effective solution for tightly constrained tasks, while humanoids make the most sense in human-designed, variable, or hazardous environments.

Manufacturing simulation as the foundation for humanoid integration

Today, Siemens leads the charge in manufacturing simulation technologies, now with a clear eye on the humanoid future. While the potential of humanoids is undeniable, manufacturers must still answer fundamental questions about where, when, and how to deploy them effectively.

This is precisely where Siemens Process Simulate becomes indispensable. Manufacturers are excited by how quickly humanoid systems can learn and evolve, but that same adaptability introduces new layers of unpredictability. Process Simulate enables teams to create a comprehensive digital twin of the production environment, including people, robots, automated equipment, and eventually humanoids, within a single, unified virtual space. Engineers can identify integration issues early, verify feasibility, refine processes, avoid resource conflicts, and validate cycle times long before anything is installed on the factory floor.

With Process Simulate, manufacturers can evaluate critical variables such as:

- Plant floor layout and collision detection

- Humanoid access to tools, bins, and machines

- Recharge station placement and downtime impact

- Cycle time and throughput analysis

- Interaction with other robots, cobots, and AMRs

- Path planning for energy and motion efficiency

- Human-robot collaboration and safe separation distances

- Humanoid selection based on task complexity and physical demands

This capability positions Siemens software as a foundational enabler for the safe, scalable, and economically viable adoption of humanoids in manufacturing.

Siemens humanoids research partnerships and the road ahead

Strategic partnerships further strengthen Siemens leadership in this domain. In March 2025, the Institute of Robotics and Mechatronics launched a research collaboration with Siemens focused on AI-based intelligent production, explicitly including humanoid robotics. This collaboration reflects Siemens long-term commitment to shaping the future of production through applied research, industrial software, and real-world deployment.

Humanoids are among the most discussed topics in advanced robotics today, and for good reason. They promise increased efficiency, smarter and more flexible manufacturing, and the ability to offload undesirable or unsafe tasks from human workers. With deep investments in simulation, autonomous systems research, and industrial partnerships, Siemens is uniquely positioned to help manufacturers move beyond experimentation and toward practical, validated humanoid deployment.

To see how Siemens software can help answer the toughest questions about humanoid integration in your production environment, check out this demonstration to see the factory of the future.

![The future of bridging humans, robots, and humanoids with Process Simulate software [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2025/11/humanoid-tecnomatix-siemens-process-simulate-human-demo-395x222.png)