Astrium achieves production efficiency with Tecnomatix

Learn how Astrium is reducing manufacturing time and costs to bring in new business

In this case study summary you will learn how quality and efficiency improvements gained through Tecnomatix software enable in-house facility to sell manufacturing services to external customers.

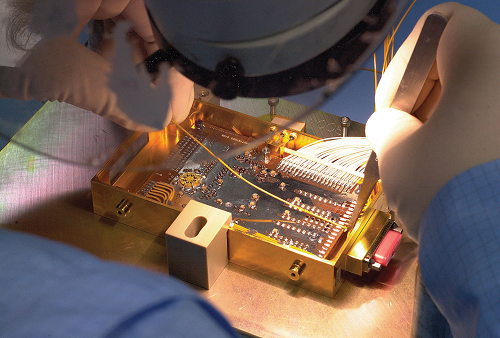

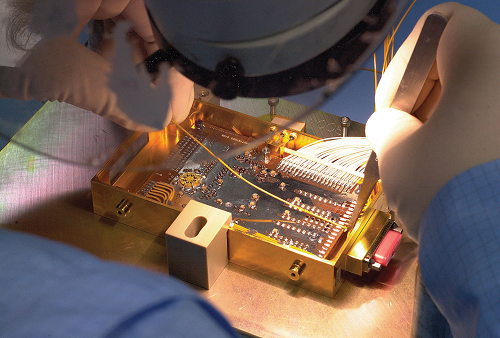

Europe-based Astrium is one of the few companies in the world that provides complete end-to-end tailored solutions for surveillance, communication and satellite navigation. It designs and manufactures customized satellites; it also provides services through its own space platforms. Being susceptible to economic and political cycles, the aerospace and defense industry has traditionally experienced periods of varying demand. A key objective for Astrium is to balance the company’s workload by providing manufacturing services to external suppliers as well as to its in-house design departments.

To be competitive in an external market, Astrium’s Payload Equipment Manufacturing Department had to cut the cost and time of manufacturing components and assemblies. Tecnomatix software from Seimens PLM Software is playing a key role in this effort.

Keys to success

- Replacing paper-based process with manufacturing execution software

- Clear visibility of lead and queue times; ability to predict bottlenecks

- Faster implementation of design changes

- Better communication among manufacturing teams

Results

- On target to achieve overall manufacturing cycle time reduction of 50 percent

- 60 percent less time spent on engineering change requests

- Five engineer days per month saved on administration

- Documentation errors reduced by 15 percent

- Overall facility quality increased

- Clean room paper costs reduced from £15k to £2k (US $30k to US $4k) per year

- Ten percent increase in manufacturing capacity

“We selected Tecnomatix on the basis of ease of use, cost and compatibility with our existing infrastructure.” Jonathan Roe, Project Manager, Astrium

Read the complete Tecnomatix customer success story in the attachment.