Additive manufacturing reshapes everything / IPC APEX EXPO

Revolutionary technologies industrialize 3D printing

Don’t miss Siemens PLM at IPC APEX EXPO 2018 , Tuesday, February 27 through Thursday, March 1, at the San Diego Convention Center, Exhibit Hall B2, Booth #2621. Meet with Siemens experts and learn about new advancements in digital manufacturing technology. Siemens PLM and Mentor help companies digitalize manufacturing and the process of turning innovative product ideas and raw materials into real products.

Visitors at IPC APEX EXPO will learn about the innovative technologies that we have to help electronics manufacturers digitalize manufacturing and realize innovation.

The 3D printing revolution is combining existing technologies with new innovations to modernize manufacturing. The result is that 3D printing technology is allowing companies to change not just what they make and how they make it, but also how they do business.

Generative design

Transform design with Convergent Modeling and automated topology optimization.

Metal powder bed fusion

Build parts with internal details, complex features and robust material properties.

Multi-jet fusion

Make plastic parts with high dimensional accuracy and print them ten times faster.

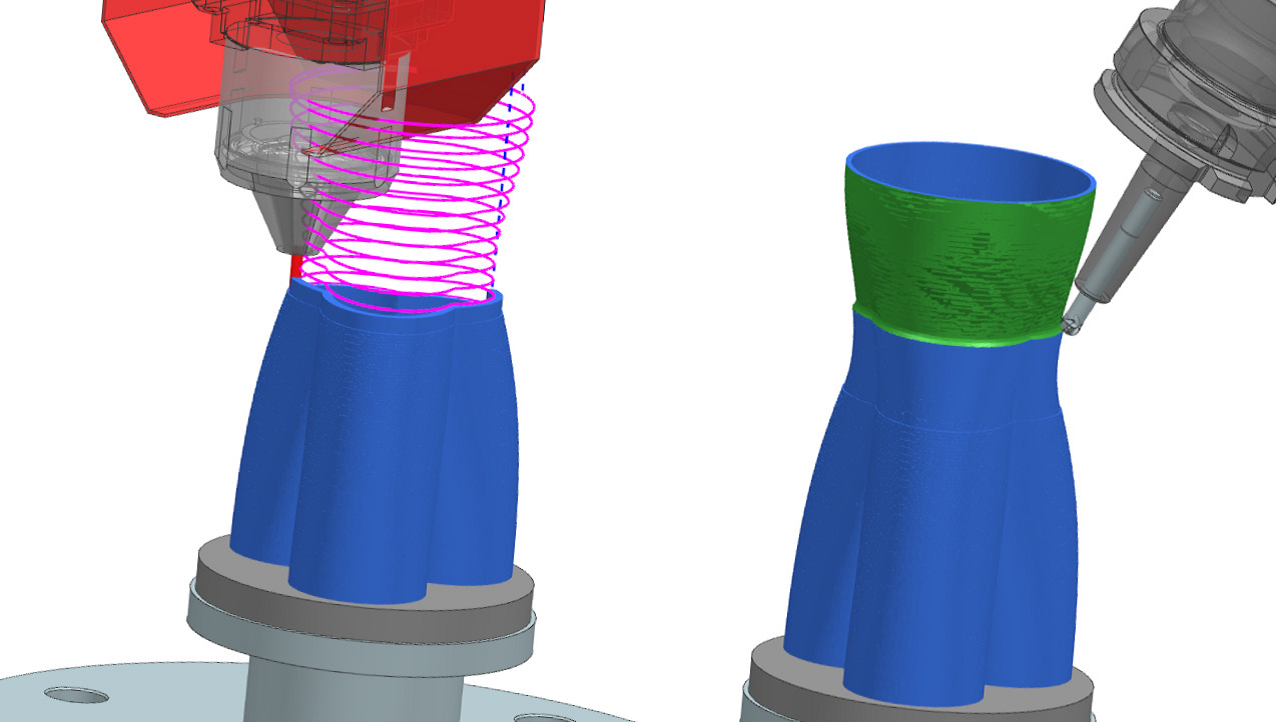

Hybrid additive manufacturing

Combine 3D printing and CNC machining in a single setup.

Multi-axis fused deposition modeling

Build composite parts in various sizes and eliminate support structures.

Reimagine products

- Easily prepare models for 3D printing

- Scan-to-print: import scan data, edit, print final parts

- Create custom anatomical implants

Reinvent manufacturing

- Combine robotics, 3D printing and CNC machining

- Create complex parts faster and easier

- Eliminate data conversion and third-party tools

- Drive all AM hardware from a single system

Rethink business models

- Use digital rather than physical inventories

- Reduce lead time

- Manufacture parts closer to point of demand

- Reduce storage and shipping costs

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)