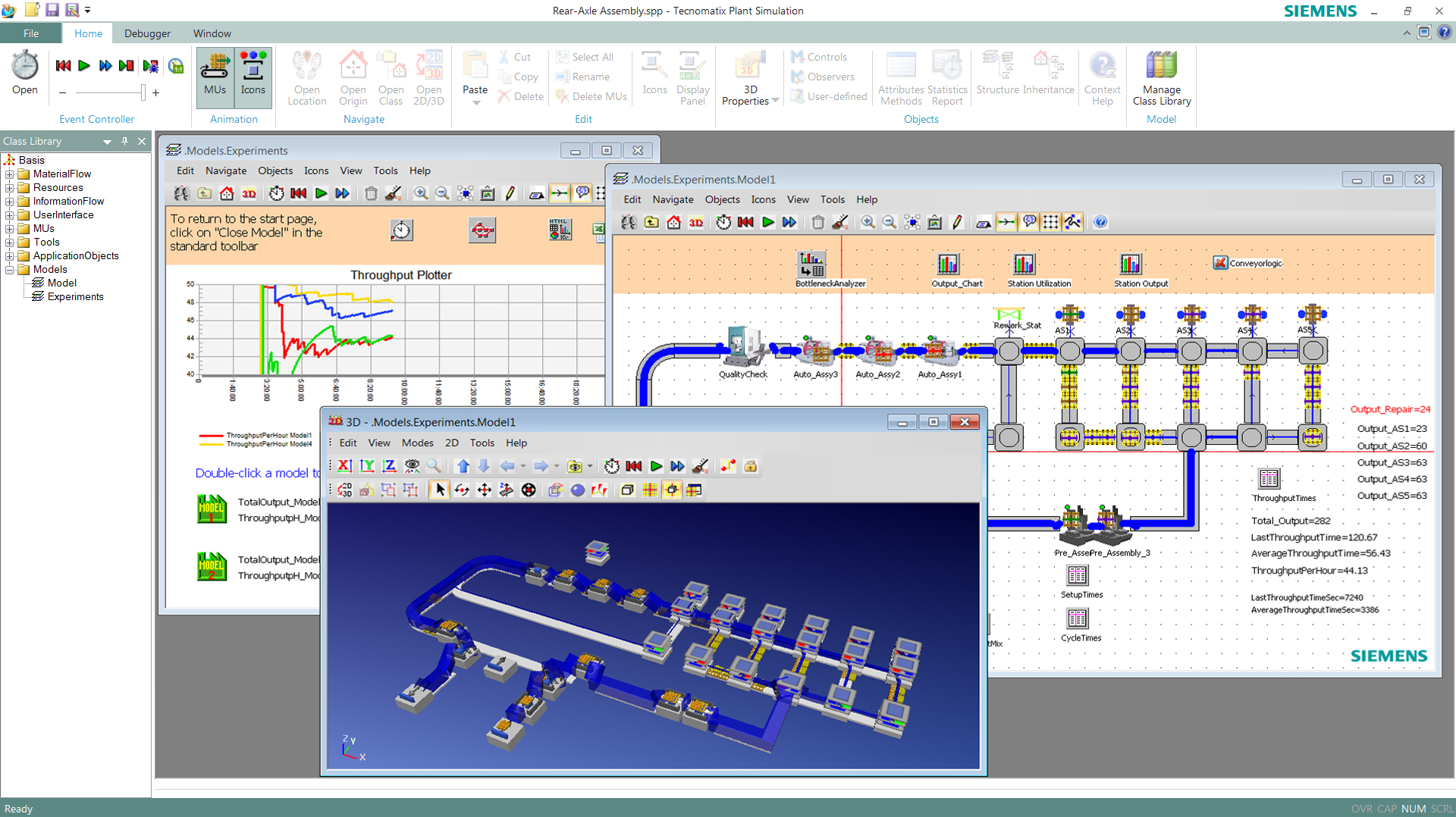

Tecnomatix Plant Simulation software featured in SMART Manufacturing magazine

Tecnomatix Plant Simulation software is featured in “Building simulation tools for non-programmer types,” SMART Manufacturing magazine, March 2017. In the story, Contributing Editor, Bruce Morey, describes how digital manufacturing’s rise will become more prevalent as computing gets more powerful and new data sources allow higher fidelity and accuracy in factory simulations.Morey explains how easy-to-use factory simulations are key to wider adoption.To round out the story, Morey interviewed Mike Rouman, senior marketing manager for Siemens PLM Software, to provide insight about the discrete event simulation software, Tecnomatix Plant Simulation.

“Most customers use a mixture of 2D and 3D simulations, typically on their desktop. It does not require a lot of computing resources and takes a matter of minutes to build a plant simulation, using a drag and drop to place objects that will give you some meaningful results,” Rouman said.Tecnomatix can be used for not only discrete event simulation but simulating both additive and subtractive manufacturing environments. “For example, we can simulate workcells or workstations using a cyclic event simulator.If I want to simulate and see my virtual robot cell operating as a function of a signal that is coming from a controller, say a PLC, and I want to check back that it works correctly, I have to simulate based on events. We can use data from these types of simulations, as well as data collected from actual operations, to feed ever more realistic plant simulations.”Rouman noted that data sources can come from IIot, MES or PLM inputs like Siemens’ Teamcenter.

Read the complete story on the SMART Manufacturing magazine website: Building simulation tools for non-programmer types.

Tecnomatix Plant Simulation software model showing energy analysis of an assembly process, charting and visualizing power consumption for production resources, highlighting in red those that consume the most energy.

Tecnomatix Plant Simulation software model showing energy analysis of an assembly process, charting and visualizing power consumption for production resources, highlighting in red those that consume the most energy.