Scaling homebuilding with Plant Simulation: How ADMARES is industrializing construction

The global construction industry faces persistent challenges: labor shortages, long lead times, limited scalability and high-cost variability. ADMARES, a Finnish construction company, is addressing these challenges by rethinking how homes are built, applying industrial manufacturing principles to residential construction. At the heart of this transformation is Plant Simulation, part of the Tecnomatix portfolio within Siemens Xcelerator.

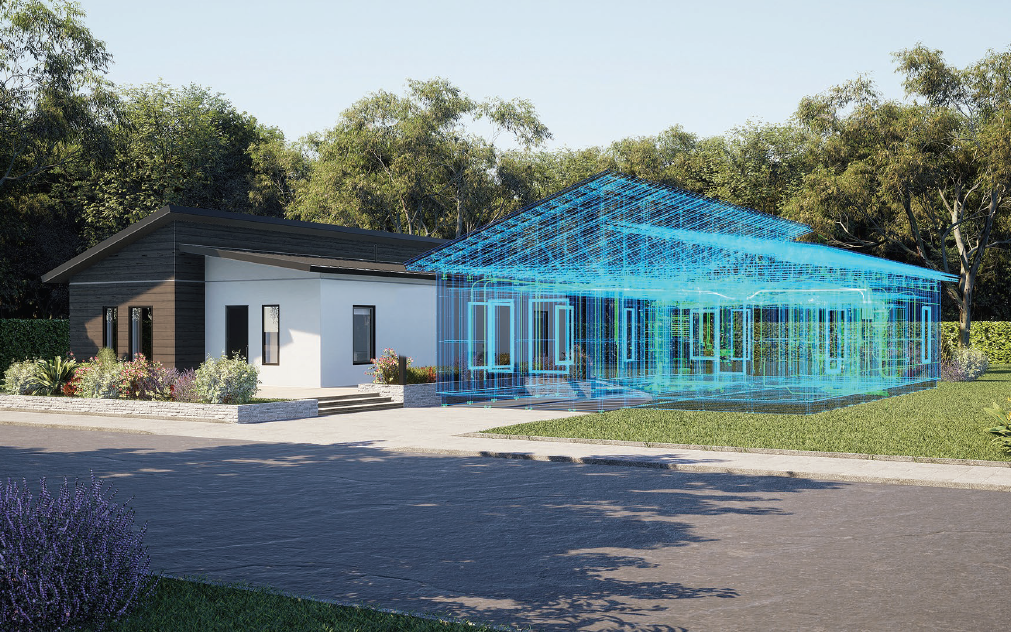

By shifting homebuilding from the construction site to a factory environment, ADMARES is enabling a scalable, automated and predictable production system capable of delivering housing at an industrial scale.

Leveraging an industrial approach to housing

Traditionally, homes are built on site using manual processes and tools, often resulting in unpredictable schedules and quality variations. ADMARES is redefining this approach by developing a fully digitalized, and productized method for manufacturing complete residential buildings in a factory.

Founded in 2016 in Turku, Finland, by Mikael Hedberg, ADMARES draws on expertise from shipbuilding and offshore industries—sectors where modular construction and industrial planning are well established. From its earliest projects, the company fully prefabricated modular units in the factory, including all technical systems, and delivered them to the site ready for immediate use. This differentiates ADMARES from conventional prefabrication approaches that still rely heavily on on-site assembly and finishing.

To scale its vision, ADMARES needed to:

- Scale homebuilding using industrial manufacturing principles

- Overcome the limitations of traditional, on‑site construction

- Automate production within a factory environment

- Plan and validate complex production systems before physical implementation

Meeting these challenges required a digital foundation that could support end-to-end planning, simulation and execution.

Plant Simulation as a foundation for smart factory planning

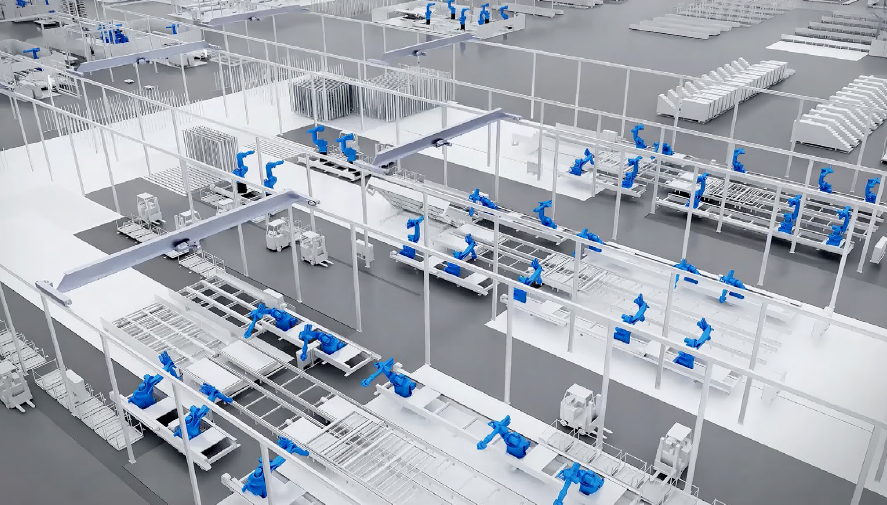

ADMARES partnered with Siemens Digital Industries Software and industry experts, including Porsche Consulting, MHP – A Porsche Company, and EDAG Group, to design a fully digital and automated smart factory for residential building production.

A central element of this initiative is Plant Simulation, which ADMARES uses to model, analyze and optimize one of the world’s largest modular housing facilities—spanning nearly 310,000 square meters.

Using Plant Simulation, ADMARES can:

- Validate production concepts long before installing equipment

- Model more than 20 interconnected production areas

- Balance cycle times and logistics

- Evaluate layout and material flow scenarios

- Identify bottlenecks during planning rather than operation

This simulation first approach supports fact-based decision making and reduces risk as the company moves from concept to execution.

Achieving efficiency before production begins

Using Plant Simulation, ADMARES validates process stability, automation levels and realistic cycle times before physical installation. The company can virtually test multiple layouts and production scenarios, enabling well-informed decisions about factory setup and investment.

This approach delivers tangible results:

- Reduced ramp up and new product introduction time

- Early identification and resolution of bottlenecks

- A predictable, robust production system that is easier to adapt

- Shorter decision cycles through simulation-based planning

Using Plant Simulation allowed us to accurately model the high manufacturing depth across more than 20 interconnected production areas and provided full transparency on key performance indicators.

Marvin Plueschke, Project Lead at EDAG Group

Transferring automotive principles to construction

ADMARES applies principles commonly used in automotive manufacturing—standardized processes, series production and automation—to homebuilding. By integrating Plant Simulation into its IT architecture, the company can simulate production variants and embed them directly into a scalable, repeatable system.

Leveraging Plant Simulation supports fact-based planning and secures major investment decisions with reliable, real-world data.

Mikael Hedberg, Founder and CEO of ADMARES

This digital approach enables continual optimization in series production, something not achievable in traditional, one-off construction projects.

Key outcomes enabled by Plant Simulation

Through the use of Plant Simulation and Siemens Xcelerator, ADMARES has:

With a maximum planned capacity of around 16,320 homes per year, the smart factory concept enables production of over 50 homes per day, demonstrating how housing can become an industrially scalable, economically viable and climate-conscious solution.

Simulating with Plant Simulation helped validate system availability of over 85 percent.

Marvin Plueschke, Project Lead at EDAG Group

Planning the future of industrialized construction

ADMARES’ approach shows how Plant Simulation bridges the gap between virtual planning and real-world execution. By embedding simulation early and using it continuously, the company created a digital factory model that connects planning, execution and optimization.

This integrated, simulation-driven foundation allows ADMARES to adapt to changing market requirements, introduce new product variants and scale production efficiently, while maintaining quality and cost control.

This simulation‑driven foundation enables ADMARES to adapt to market changes, introduce new homebuilding variants, such as updated unit types, redesigned modules, or new façade and interior packages, that can be added without disrupting production flow.