Transforming Parcel Hubs: How Digital Twins are Paving the Way for Smarter, Ergonomic Operations

In today’s competitive logistics landscape, operational efficiency and employee welfare are not mutually exclusive goals. In a “Virtual Parcel Hub”, researchers from the Institute of Logistics Engineering at Graz University of Technology (TU Graz) demonstrated how advanced digital solutions can create a harmonious balance between productivity and ergonomics. This case study, supported by Siemens Xcelerator Portolio, including Plant Simulation and Simcenter HEEDS, offers valuable insights for organizations seeking to optimize their operations without compromising on employee care.

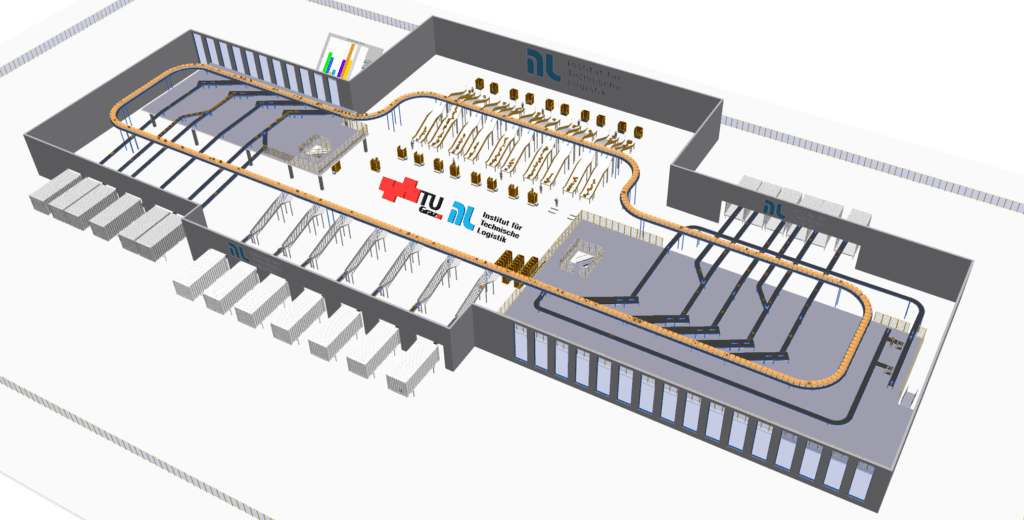

A Detailed Digital Twin

The initiative began with the creation of a digital twin – a comprehensive virtual model of an entire parcel hub. Using Siemens Plant Simulation software, the team meticulously replicated a typical Parcel Hub’s layout, processes, shipment characteristics, and even the nuanced work routines of its employees. This detailed model enabled the researchers to test various operational scenarios in a controlled environment.

The digital twin allowed the team to refine processes and identify adjustments that could reduce unnecessary physical exertion and improve workflow efficiency. Multiple “what-if” scenarios were tested, ensuring that every change was both practical and beneficial from an operational standpoint.

Automating Optimization with Precision

Building on the digital twin, Siemens Simcenter HEEDS was employed to automate the optimization process. This advanced tool systematically explored a wide range of configuration possibilities, seeking solutions that would not only enhance operational performance but also improve ergonomic conditions for workers. The optimization process proved to be transformative:

• Walking distances were reduced by up to 70%, significantly diminishing the cumulative physical strain on employees.

• Workload imbalances were cut by approximately 54%, ensuring a more equitable distribution of tasks across the workforce.

These outcomes underscore the potential of combining digital simulation with systematic optimization techniques to achieve both efficiency gains and improved worker welfare.

With the combination of Plant Simulation and Simcenter HEEDS, we demonstrated that ergonomic improvements and operational targets are not mutually exclusive.”

Prof. Dr. Domenik Kaever, Head of the Institute of Logistics Engineering, Graz University of Technology

Integrating Technology with Human-Centric Design

What distinguishes this project is its dual emphasis on technology and human-centric design. The adoption of a digital twin was not merely a technological upgrade; it was a strategic decision to place employee well-being at the forefront of operational redesign. By simulating different scenarios, the research team was able to predict the real-world impact of process changes on daily work routines. This proactive approach ensured that modifications to the workflow would mitigate physical strain and reduce fatigue over the long term.

For employees, these improvements translate into tangible benefits. Reduced walking distances mean less physical exertion, which can lead to improved health outcomes and a reduction in workplace injuries. Meanwhile, a more balanced workload contributes to a more stable and satisfying work environment, fostering higher levels of productivity and morale.

A Strategic Vision for the Future

The insights garnered from the TU Graz parcel hub case underscore a critical lesson for modern logistics operations: technological advancements must be leveraged not only to drive operational efficiency but also to create supportive, sustainable work environments. By integrating advanced digital tools with a clear focus on employee experience, organizations can unlock significant performance improvements while safeguarding the well-being of their workforce.

This case study serves as a model for logistics operations worldwide, illustrating how investments in digital transformation can yield dual benefits: enhanced productivity and improved employee satisfaction. It provides a compelling argument for further exploration of digital twin technology and automated optimization systems in other industrial settings.

Shaping the future of modern logistics

The TU Graz parcel hub project is a prime example of how the thoughtful integration of innovative digital tools can drive substantial improvements in both operational efficiency and employee well-being. The use of Siemens Plant Simulation and Simcenter HEEDS demonstrates that with a strategic, human-centered approach, it is possible to optimize complex processes without losing sight of the ultimate goal: creating a better, healthier workplace.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)