Transforming Manufacturing Simulation with AI: BSH’s journey with Siemens Process Simulate Copilot

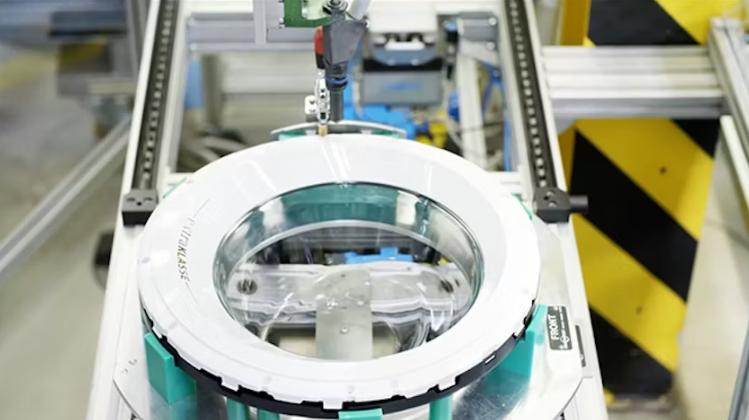

Over the last years BSH and Siemens have worked together extensively on 3D manufacturing simulation and the value it brings in production planning and validation. BSH is one of the world’s leading home appliance manufacturers and produces a wide range of appliances — from washing machines and refrigerators to ovens and vacuum cleaners — under global brands such as Bosch, Siemens, Gaggenau, and Neff, along with several regional brands.

BSH uses Process Simulate, Siemens’ 3D manufacturing simulation solution, to address the most challenging engineering tasks both in automation and robotics and in manual assembly applications. This includes the implementation of collaborative robots for various applications, assessing ergonomics impacts during manual tasks planning, collaborative design reviews utilizing state of the art VR technology and many other aspects. As part of our continuous collaboration, we introduced our recently developed Agentic AI capabilities to the team at BSH and are working together with them on leveraging those capabilities to empower BSH engineers to address complex engineering tasks quickly and efficiently, ensuring high quality and optimized outputs.

Democratizing Expertise Through AI

BSH Home Appliances, Europe’s leading home appliance manufacturer, recently partnered with Siemens to explore how artificial intelligence could bridge this expertise gap and enhance manufacturing simulation capabilities.

In today’s rapidly evolving manufacturing landscape, simulation tools have become essential for optimizing production processes. However, these powerful tools often come with steep learning curves that can limit their accessibility. BSH faced two significant challenges in their manufacturing operations:

Expertise Barrier: Process Simulate, while powerful, required significant training and expertise to use effectively. This created a bottleneck where only specialized engineers could leverage the software’s full capabilities.

Time-Consuming Optimization: Manual optimization of manufacturing processes – such as pick-and-place operations and screwing sequences -demanded considerable time and expertise, often resulting in less-than-optimal solutions.

We have been using Process Simulate on Teamcenter and know all the robotic capabilities it has, but what we would like is a tool that also offers value for engineers who are not robotic experts,” explains Ezquer Gonzalez Ignacio, Product Owner of Process Simulate and Plant Simulation at BSH.

The workshop, which included both expert and beginner users, revealed the copilot’s significant potential to transform manufacturing simulation:

The Solution: AI-Powered Process Simulation

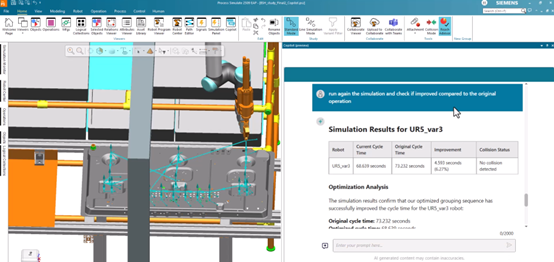

Through Siemens’ Early Access Program, BSH tested the innovative Process Simulate Copilot – an AI assistant seamlessly integrated with their existing Process Simulate software. The implementation focused on two key use cases:

- Pick-and-Place Operations: Testing whether the copilot could guide users (especially beginners) through creating pick-and-place operations and optimizing via positions to reduce cycle time.

- Screwing Operations: Evaluating if the copilot could optimize routing sequences more effectively than manual methods.

Accelerated Optimization: When working effectively, the copilot reduced optimization time from potentially hours of manual work to just minutes.

Enhanced Quality: In several cases, the AI-generated solutions outperformed manually optimized sequences.

Lowered Learning Curve: The copilot provided step-by-step guidance that helped beginners navigate complex operations without extensive training.

“Everybody was very excited about it. They had very positive expectations… they really hoped that it would increase their speed. It will make it much easier also for beginner users, so they don’t need to do all the training, but they can just learn how to use Process Simulate by doing,” shares Tatjana Scheele, a working student at BSH conducting research on Process Simulate capabilities.

Collaborative Evolution: Addressing Early Challenges

As with any cutting-edge technology, the workshop revealed opportunities for enhancement that the Siemens team eagerly embraced as part of their development roadmap. The BSH team noted that response consistency could be improved, with the copilot performing exceptionally well in some scenarios while requiring refinement in others.

“The main thing about the copilot that we’re looking forward to seeing evolve is their reproducibility… when it worked, it was impressively efficient – you got the optimized sequence immediately and did not have to spend time figuring it out yourself,” notes Tatjana Scheele.

In one particularly impressive case, the copilot provided exact coordinates for a pick operation – a capability that surprised even the workshop facilitators. This demonstrated the technology’s potential, while also highlighting areas where consistency could be enhanced.

What stood out was Siemens’ receptiveness to this feedback. The Siemens team viewed these insights as valuable guidance for their development roadmap. This collaborative approach underscores Siemens’ commitment to developing AI solutions that truly address customer needs.

The AI path forward for manufacturing simulation

Based on the workshop feedback, Siemens and BSH have outlined several focus areas for continued development:

- Enhancing Consistency: Improving the reproducibility of results across similar scenarios

- Streamlining Communication: Developing more concise responses that deliver key information efficiently

- Visual Guidance: Incorporating more visual instructions to complement text-based guidance

- Real-World Testing: Expanding testing to include actual production use cases from BSH factories

“I see that’s a tool that could help us a lot in the future,” notes Ezquer Gonzalez Ignacio, highlighting BSH’s enthusiasm for continuing to explore the copilot’s potential.

The BSH-Siemens collaboration demonstrates how AI can democratize access to advanced manufacturing simulation tools. By lowering the expertise barrier and accelerating optimization processes, the Process Simulate Copilot enables more team members to contribute to manufacturing excellence.

“If you have somebody who’s not super into that topic, the copilot can assist much more and give you a better optimized sequence than you could have done yourself,” explains Tatjana Scheele, highlighting the technology’s potential to empower users at all skill levels.

As manufacturing continues to evolve in the Industry 4.0 era, tools like the Process Simulate Copilot represent the future of human-AI collaboration in industrial settings. By combining human creativity with AI-powered optimization, manufacturers can achieve new levels of efficiency, quality, and innovation.

The BSH case study illustrates that we’re just beginning to tap into the transformative potential of AI in manufacturing simulation. What makes this partnership particularly valuable is the open dialogue between customer and developer collaborative approach that ensures the technology evolves to meet real-world manufacturing needs.

As these technologies mature through this kind of customer-focused development, they promise to make advanced manufacturing tools more accessible, efficient, and powerful – ultimately helping companies like BSH maintain their competitive edge in an increasingly complex global marketplace.