Weight and Balance – Plan, Track and Meet Design-to-Target Objectives

Weight and Balance Key Drivers

To be considered best-in-class a product must rank high across many categories such as performance, safety, durability, reliability, appearance, and more. The focus of this blog is on the weights and balance of your product and its impact on many of these categories.

Product manufacturers are placing a lot of focus on planning, tracking, and managing mass properties from concept through service and all other product development phases in-between to monitor, react and influence product direction early in the development cycle and achieve design-to-target objectives, meet corporate standards as well as secure necessary approvals from certification authorities.

Here are some of the important considerations during product development process for managing mass properties information:

- reduce the cost of maintenance of managing mass properties data in offline databases

- reduce manual reconciliation efforts to keep weights in Sync with Product structure

- change management and traceability to understand the reason for change

- create reports by system, functional and other relevant product architectures

- forecast weight based on risks and opportunities to track the roadmap to achieve targets

- create mass distribution reports for loads and structural analysis

- and many other security and access related needs

It’s important to have the right tools that simplify the management of weights and balance data so the design and product teams can focus on solving real engineering problems and right-sizing the product and achieving program targets without incurring the cost of delays as a result of overweight designs or out of balance products.

Challenges & Current Reality

Reporting on the weight and balance status against the targets is traditionally done with several reporting tools, both commercial and homegrown. The challenge with this approach is that weight engineers are just reacting and reporting on the status against the targets and not proactively influencing product direction throughout the product lifecycle.

Managing weights data in separate databases disconnected from PLM adds to the overhead and maintenance as they must collect inputs from multiple sources such as ECAD/MCAD tools, Excel files, supplier specification documents and then reconcile them manually against the product bill of materials without robust change control mechanism that keeps track of these changes.

This lack of single-source-of-truth for weights data adds to the cost of delay as it typically lags design development, potentially resulting in overweight designs being released. The need to generate weight reports organized by breakdowns other than how the product is designed adds to the complexity if the weights information is not maintained in a single source.

The need to develop a product that is within approved weight and balance limits and tracking the status right from concept through design development and final production and validating for all configurations and payload conditions consistently in real-time are critical for product success.

Doing so ensures that your product meets or exceeds your customer’s expectations and more importantly avoids late changes that are often expensive and potentially could delay product release.

How Can Teamcenter Influence Weight and Balance

Building on the strengths of Teamcenter’s BOM and Configuration Management, Teamcenter’s weight management solution addresses the tool and process shortcomings that customers face today and eliminates the need for managing weights in an offline database disconnected from PLM and CAD systems.

With this integrated approach, the Teamcenter weight management solution enables all key stakeholders in an organization to collaborate effectively on a single PLM platform while providing independent access control and lifecycle to plan, manage and evolve targets. Stakeholders may also manage weight estimates, as-weighed and other weight types to support different phases of the product lifecycle from concept through production.

Maintaining full digital traceability starting from requirements is another key aspect of the Teamcenter Weight and Balance solution that helps you establish end-to-end digital traceability from requirements to the corresponding product and their weights. This traceability will help continuously assess and maintain product compliance against corporate and regulatory standards.

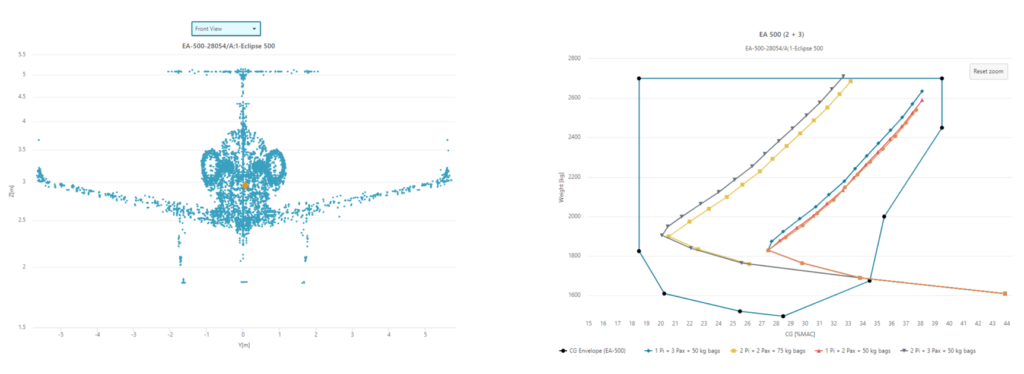

You can generate on-demand weight and balance reports of any product size and configuration to view status against the target in real-time at all levels of product breakdown with warning indicators and relevant engineering charts that help track weights against targets and impacts of payloads.

Stay tuned to learn how we plan to address cost and carbon footprint management in Teamcenter to track, analyze and calculate in order to make informed decisions to achieve cost and climate targets.

Learn more about weight and balance and bill of materials (BOM) by reading below:

About the Author

Venkat Gonuguntla is a product manager for Teamcenter bill of material management with over 15 years of experience in different roles supporting customers in the automotive industry, aerospace, heavy machinery, and high-tech industries.