Simulation Data Management & Digital Transformation

What is the goal of digital transformation? For my four-year-old nephew, it is to order a pizza using an emoji. For CAE analysts, it’s effectively searching and navigating massive amounts of distributed and disconnected data with simulation data management.

Simulation Data Management Breaks Data Silos

So, what is the common link between my nephew’s pizza order and CAE Analyst data? In both cases, the goal is to radically improve productivity, which is the ultimate goal of digital transformation. The Nine Elements of Digital Transformation by the MIT Sloan Review provides a good overview of this topic. The age of digital transformation means gone are the days of doing things the old way. This is true for managing simulation data in silos and on a shared filesystem. Instead, simulation teams should look into simulation process and data management (SPDM) as a productivity source.

Simulation teams are reaping the many benefits of a SPDM system. You can read the blog “Why Do You Need Simulation Process and Data Management System?” for more details on how.

For instance, one of the foundational elements of digital transformation is a personalized experience. More specifically, one that is simple to use and easy to learn. This is an especially true need for a simulation analyst. Over 50% of an analysts’ time is spent seeking and providing information, according to “How analysts spend their time (HASTT)” study by Rolls-Royce Aero-Engines.

Therefore, a personalized analyst experience that consists of a meticulously tailored home page, tabs, etc., is essential to boost productivity when searching through and managing simulations.

Another foundational element of digital transformation is automation. Automation involves applying technology to make processes more efficient by running themselves. This can also increase transparency and reporting capabilities. In short, automation offers productivity boost that results in a faster time to market for simulation teams.

Reducing Impediments So You Can Do Your Best Work

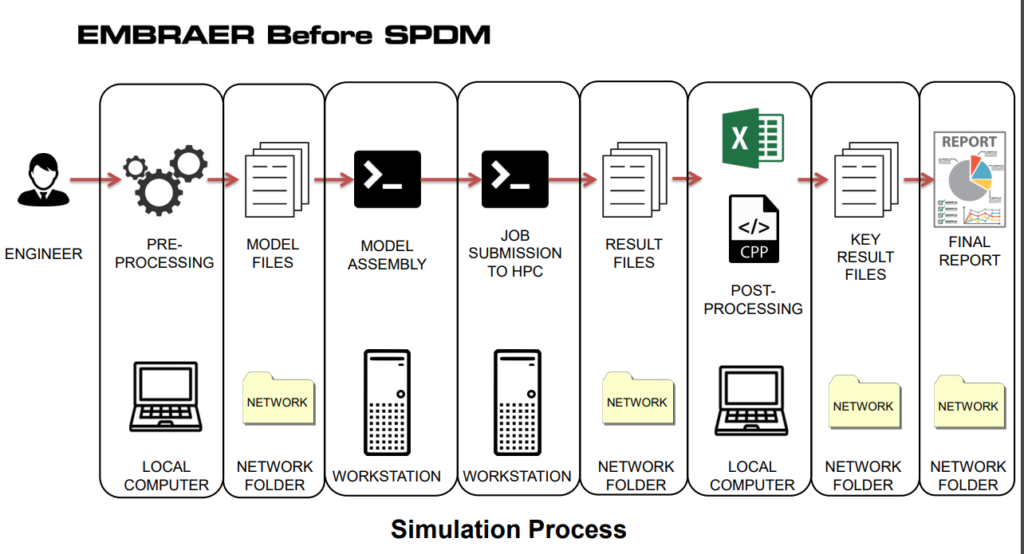

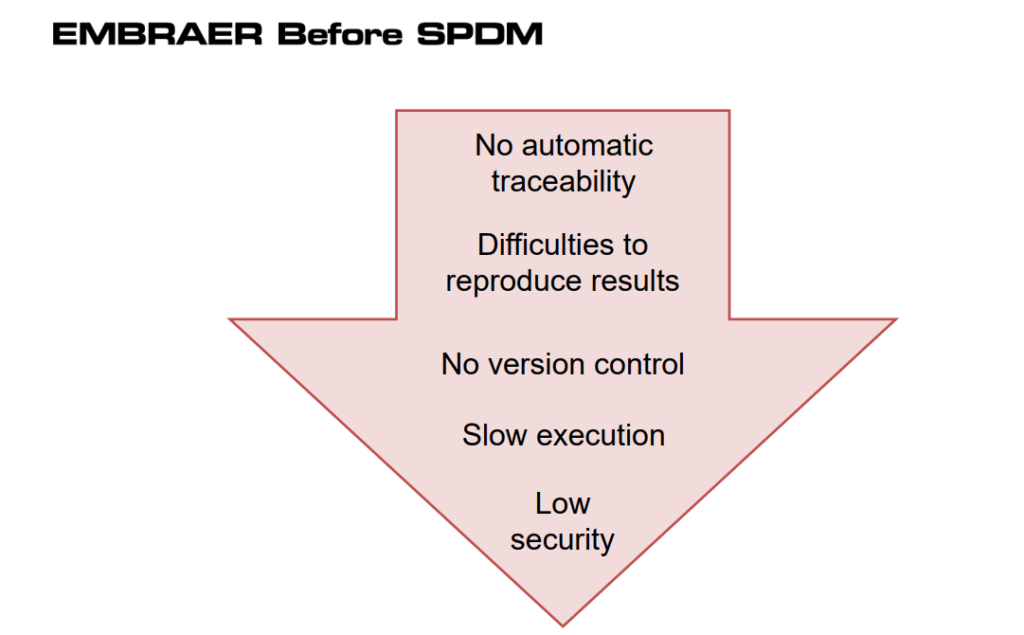

Gartner contends that digital transformation is not about taking people out of the process. Quite the opposite. It is about getting them back to doing what they are good at by reducing simulation teams’ impediments. As highlighted in the article, How simulation is managed at Embraer, before implementing an SPDM system, managing simulation processes and data is very time-consuming and error-prone.

In addition, since the execution speed is extremely slow compared to compiled codes, there was a great risk of losing the track of data done over a period of time as it was stored in many network folders and individual workstations. The use of an SPDM solution not only solved the above problems but through automation and personalization, led to a trifold increase in productivity at Embraer.

Teamcenter Simulation Increases Your Productivity

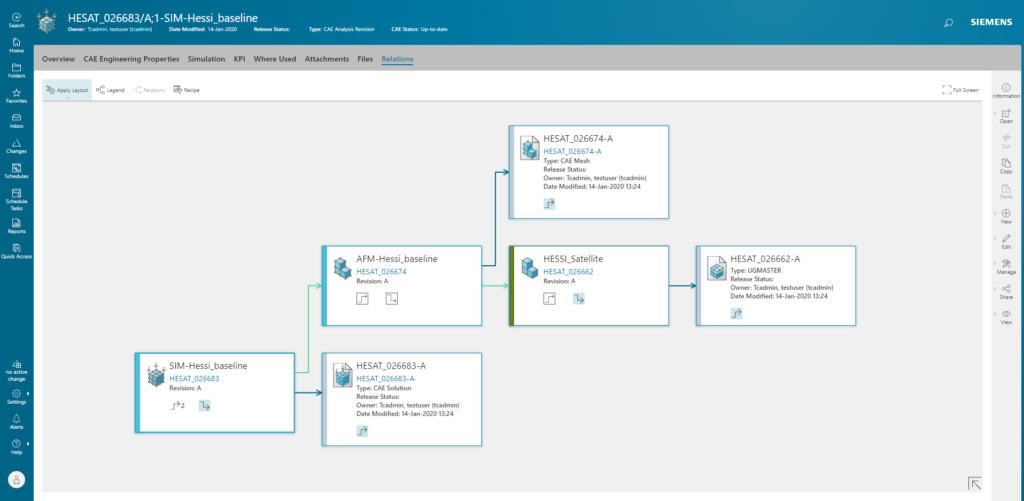

Certainly, Teamcenter Simulation with its Active Workspace client containing a tailored interface for CAE Analysts through “Analyst Workspace” and automation tools through workflows, structure maps offer analysts a path to boost productivity. In addition, Teamcenter Simulation offers capabilities to

- Capture and manage various simulation artifacts with metadata

- Manage CAE bill of materials

- Search and find simulation data

- Have traceability from requirements to results

- Launch vendor-independent simulation tools

- Execute simulation workflows

- Visualize and communicate results and reports

Although a CAE Analyst wouldn’t be able to order a pizza with an emoji, they can certainly experience productivity from Teamcenter Simulation with Active Workspace.

About the Author: Bhanu Peddi helps facilitate solutions dealing with ever-increasing simulation data in the current role as Product Manager of Simulation data management solution. These solutions, in turn, allow organizations and simulation groups to reduce costs and speed time to market. Bhanu has over nine years of experience in PLM, simulation, and data management domains.