Combine Quality with PLM best practices

Opportunities and advantages of quality management and PLM best practices.

Product and process complexity continues to grow in importance for many businesses today, influencing new business models. Manufacturers must redefine roles for PLM (product lifecycle management), and QMS (quality management system) must expand beyond traditional paradigm. QMS best practices needs to be applied across the whole product lifecycle.

Why a new approach for PLM and QMS

PLM industry analyst CIMdata released a commentary, “A broad approach to Quality Management. Closed-Loop Quality Solution Leverages Teamcenter Backbone”.

The commentary advises readers on what to look for the quality paradigm in connection with digital threads. The core topic is the importance of integrating PLM and QMS processes seamlessly across the product lifecycle. A digital twin PLM solution comprehends changing consumers behaviors and evolving manufacturing procedures. Quality management best practices applies to all types of processes and their use improves as PLM systems enable an accurate digital twin. Therefore, executives need to bridge the gap between different domains.

Leveraging the best capabilities of QMS and PLM

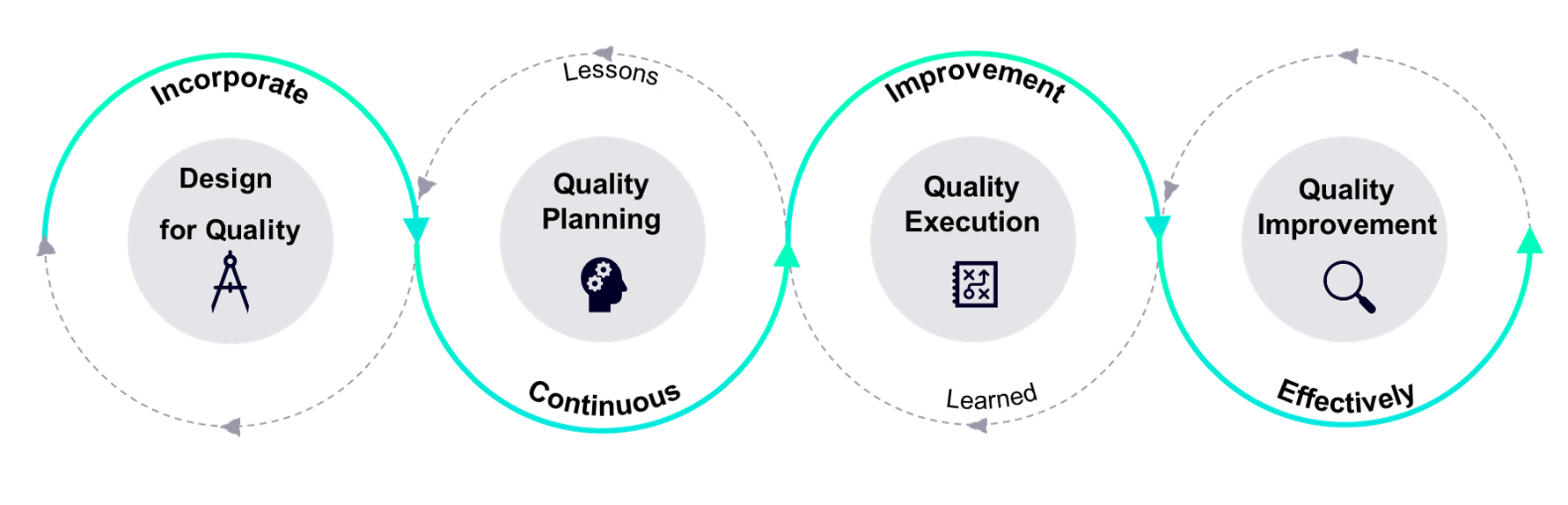

CIMdata analysts explain the meaning of integrating PLM and QMS processes seamlessly across the product lifecycle. Closed-loop quality broadens the domain of quality management to the complete closed-loop lifecycle of products. Executives with digital transformation programs can realize the advantages of a new quality paradigm.

By reading the abovementioned analysis, you will learn:

- Evaluation of Quality Management responsibility and how it is expanding across the value chain.

- Analysis of the quality paradigm in connection with digital twins and the digital thread.

- Possibility to leverage the concept of Bill of Quality (BOQ) to face challenges related to increased product complexities. Siemens BOQ comprehends all the information that describes a product from the quality processes perspective.

The right integration strategy with Teamcenter

Siemens extends the conventional Plan-Do-Check-Act (PDCA) cycle in Quality Management to engineering and manufacturing domains.

Teamcenter Quality is a product family that is working seamlessly with several domains on the Teamcenter Collaboration Platform.

Leveraging additional elements of the Teamcenter portfolio, Teamcenter Quality provides a closed-loop approach from design to manufacturing on the shop floor and backwards. The combination of modules allows you to close the loop on quality processes in Teamcenter, which is part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software.

Learn more about advantages of the new paradigm of Quality Management by leveraging on the Teamcenter Quality.