PCB Design and Data Management is Key to Integrated Product Development

Effective PCB Design and Data Management is a key component of design team productivity.

PCB Deign and Process ManagementYou have multiple design sites and each have their own data storage, workflow and change processes. As a result PCB designers spend up to 30% of their time looking for design information … frequently find and use the wrong version of data … and then spend additional time correcting data integrity issues. Do these issues sound familiar? We know how frustrating that is and let me tell you, it doesn’t have to be that way.

PCB Deign and Process ManagementYou have multiple design sites and each have their own data storage, workflow and change processes. As a result PCB designers spend up to 30% of their time looking for design information … frequently find and use the wrong version of data … and then spend additional time correcting data integrity issues. Do these issues sound familiar? We know how frustrating that is and let me tell you, it doesn’t have to be that way.

Intelligent management of PCB design data is a strategic issue for every company and integrating them with PLM can eliminate those issues that are so detrimental to engineering productivity that we just talked about.No matter which ECAD system (or systems) you use, or even how geographically distributed your sites are integrated with PLM, we enable you to quickly and easily find, share, and re-use PCB data and design processes across your organization.

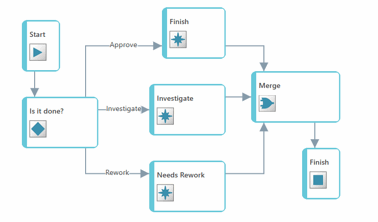

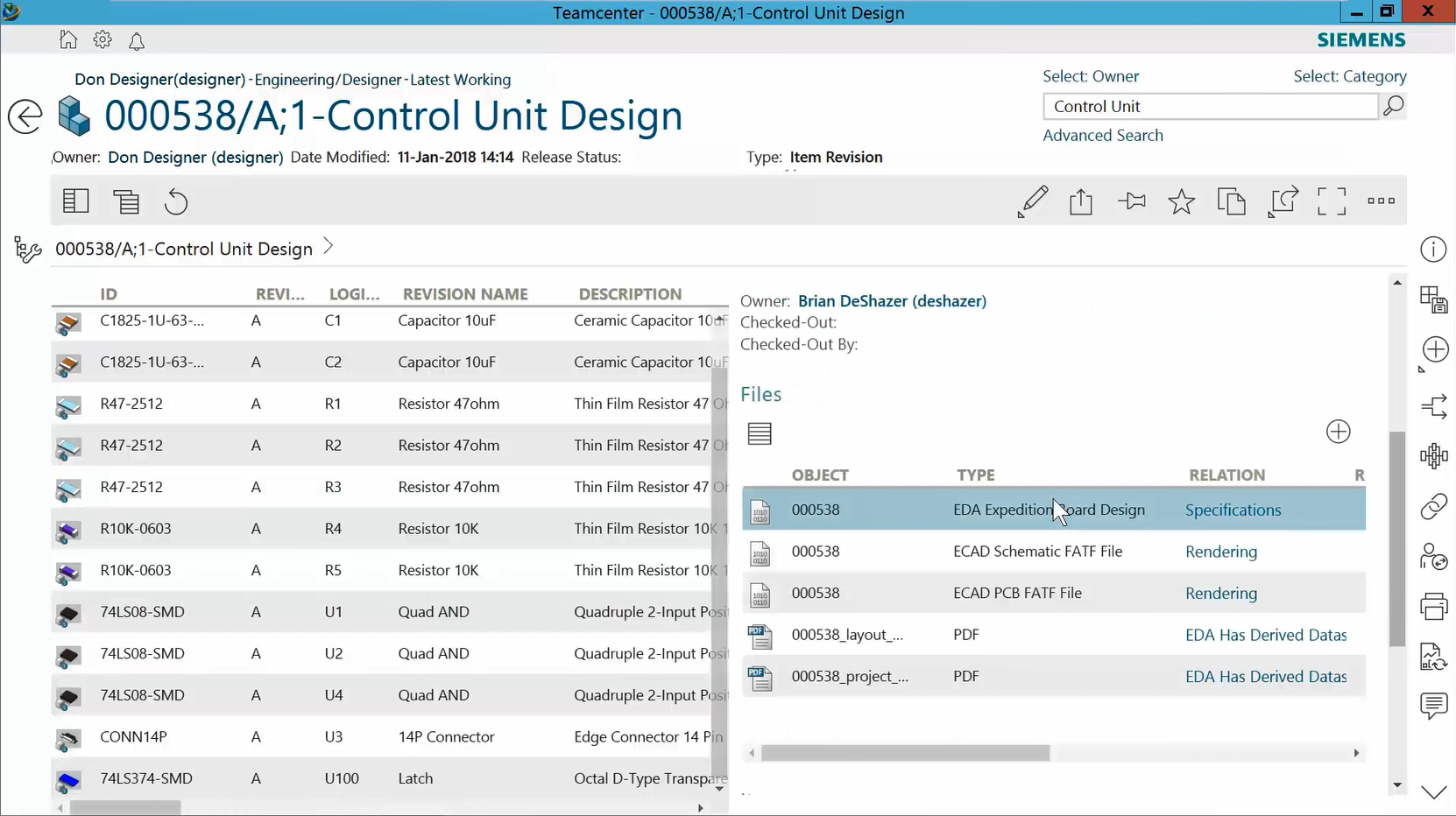

PCB Design Management within PLMWorking in your ECAD tool’s native environment, Teamcenter provides the PCB design with access to a host of PDM and PLM capabilities such open, save, check-in, and check-out designs as well as executing structured workflows and change processes.

PCB Design Management within PLMWorking in your ECAD tool’s native environment, Teamcenter provides the PCB design with access to a host of PDM and PLM capabilities such open, save, check-in, and check-out designs as well as executing structured workflows and change processes.

All the information associated with the design, as well as the information necessary for a smooth transition to the contract manufacturer or your internal manufacturing operations, are managed under each revision of the design. To ensure the integrity of the data, company defined security and access controls prevent unauthorized access to the data.

Watch this video(embedded below) to see for yourself how you can use Teamcenter for PCB data management to increase productivity and save time by capturing, managing, finding and re-using the right ECAD design data and processes no matter where it’s located.

Look for other PCB design and data management videos that highlight how Teamcenter can help you eliminate inconsistent and inaccurate PCB part library data, foster ECAD-MCAD co-design, visualize and share information across disciplines and organization functions as well as more accurately validate your PCB’s readiness for release to manufacturing.