Leveraging the Business BOM for Better Design Work Contexts

Your Business BOM and the Techniques that Teamcenter Supports

We have previously explored the benefits of part-design separation within the PLM system in Defining the Part Bill of Materials and have discussed new tools and techniques available in Teamcenter to facilitate the creation and management of work contexts for Design validation in Introducing Smart Discovery.

In this article, allow me to tie these two threads together and discuss some of the advantages of providing relevant design contexts by leveraging the business BOM and the techniques we support in Teamcenter to facilitate this.

The Digital Twin and Bills of Materials

You have likely seen many references to the now ubiquitous ‘digital twin’, which refers to the process of establishing the entire ideation to production, and maintenance lifecycle in the ‘virtual’ world.

Central to the establishment of this digital twin is the association between the ‘business’ or ‘physical’ BOM and the ‘virtual’ design data. The BOM is the list of parts required to build a product, as released by engineering and enhanced and consumed by other enterprise disciplines, and critical to driving production, while the ‘virtual’ design is the set of 3D CAD designs, software, and electronic designs that define and qualify the digital definition of the product.

In Defining the Part Bill of Materials, we discussed some of the advantages of managing the BOM within the PLM system and in close coordination with design data. One key benefit of doing so is direct access to design data from the BOM and the use of the combination to drive more relevant and on-demand work contexts for design validation.

Ensuring Relevance of Virtual Geometric Design Validation

Virtual geometric design validation of product designs is not a new discipline. This has been in practice since the advent of 3D modeling and analysis software. Great value lies in the connection of the physical BOM and configuration data to geometric validation activities so that this validation can indeed be in the context of product that is being planned to be produced at plants and can eliminate costly prototypes, errors and rework. However, in practice this connection has historically been arduous at best, involving establishing elaborate multi-system integrations and ‘overnight’ routines to validate certain reference configurations. In some cases still, this validation is done in a purely ‘design’ context – ie. without any true tie-in to the business BOM.

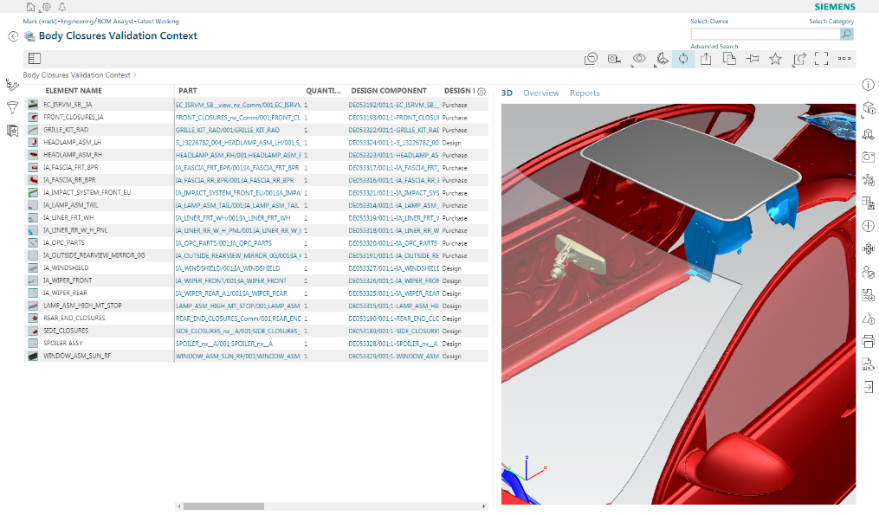

How can a PLM tool better enable this process? An integrated product definition supports smarter work contexts for design validation: based on the BOM and configuration that drives production, not restricted to only ‘reference’ configurations. This is enabled by mastering or reflecting physical BOM, configuration, Design within a single system of reference that supports advanced context management capabilities.

In a previous article Introducing Smart Discovery, Chris Scheffer has discussed techniques to efficiently find information and quickly load only the specific data needed for a particular task when working on designs for large and complex products.

Constructing such work contexts for design validation needs to include configuring and filtering based not only on design characteristics (design variability, spatial proximity, design attributes etc.) but also based on physical BOM  characteristics such as product variant and effectivity information, properties of Parts (weight…), their use specific characteristics (torque…), procurement information (make/buy, vendor), serviceability properties, etc. etc.

characteristics such as product variant and effectivity information, properties of Parts (weight…), their use specific characteristics (torque…), procurement information (make/buy, vendor), serviceability properties, etc. etc.

How do we support this while providing separation of the business BOM and design lifecycles?

In other words, can we support the usability and navigability of a single structure while maintaining the flexibility of separated BOM and Design lifecycles? Such CAD – BOM separation and alignment is often touted as a holy grail for PLM. Managing complex products absolutely requires such capability from the PLM system.

A few key enablers we have introduced in Teamcenter to support this are:

- Advanced model for BOM and Design separation, alignment and release

- A single presentation view of the BOM with aligned designs

- Flexible organization of product data including multiple organizational views of the same data

- Powerful configuration engine that can ‘solve’ and filter based on BOM, aligned Design or both in combination

- Intuitive creation and management of advanced recipes to filter based on variant, effectivity, revision, property, organizational, etc. information

- Persistent work contexts that can be refreshed on demand and drive collaboration, release etc.

- Automation enablers for CAD-BOM lifecycle separation and alignment

These capabilities delivered on Active Workspace with its task and role focused ‘one click’ user paradigm provide a compelling environment for engineers to manage complex work contexts for design validation with ease of use.