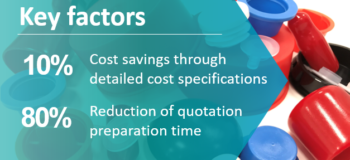

Essentra Components Achieves Cost Savings Up To 10%

Even the smallest components play a big part – Essentra Components is a global leader in manufacturing and distributing plastic injection molded, vinyl dip molded and metal items.

The company is focused on being a low-cost producer, so they can secure revenue growth at attractive margins, and facilitate continuous improvement programs with tight cost controls and productivity gains, serving to reduce conversion costs.

With the integrated calculation system for component and tool costs from Siemens, Essentra Components delivers cost-effective, high-quality products in response to customer needs. Essentra is using the global costing solution in the bidding phase to deliver fast and accurate costs worldwide.

“Quote generation is done today within one hour, as opposed to five hours before we had Teamcenter product cost management, so we save 80% of our time.”

Derek Bean, Manager, Divisional Engineering Solutions Essentra Components

The cost estimators at Essentra consolidate and verify the cost results in terms of plausibility, competitiveness, opportunities and risks with the help of the Profitability Analysis module in Teamcenter Product Cost Management. This involves a comprehensive overall analysis, which includes which costs are incurred, which revenues are calculated, how the cash flow is structured and what individual key figures look like.

“A better understanding of a project’s profitability and the effects of uncertainties, such as material price changes, currency fluctuations, etc., is now provided by Teamcenter Product Cost Management. This allows us to immediately approve financial offers.”

Derek Bean, Manager, Divisional Engineering Solutions Essentra Components

To receive a detailed view on project you can read the success story here. You can also visit our web site to learn how to achieve cost savings with Teamcenter Product Cost Management.