Accelerating Lead Times for Engineer to Order (ETO) Processes

Timing is everything. Whether you’re talking about your golf swing, the launch of a new product, or selling Engineer to Order equipment. Timing is especially important when it comes to responding to a customer’s request for proposal (RFP). How quickly you respond can signal how interested you are in the business, how experienced your company is in providing a solution, and how responsive you will be as a vendor if selected. Ultimately, how quickly you respond can be a major factor in winning the business; or not. Responding quickly to a RFP can be challenging enough when you have an existing product to sell. It is orders of magnitude more challenging when you are selling a custom product that must be engineered to order.

See Rulestream ETO software for yourself by attending one of these on-demand webinars: An Introduction to Engineer-to-Order Process Automation for Industrial Machinery using Rulestream or Create Custom Engineering Applications with Minimal Coding.

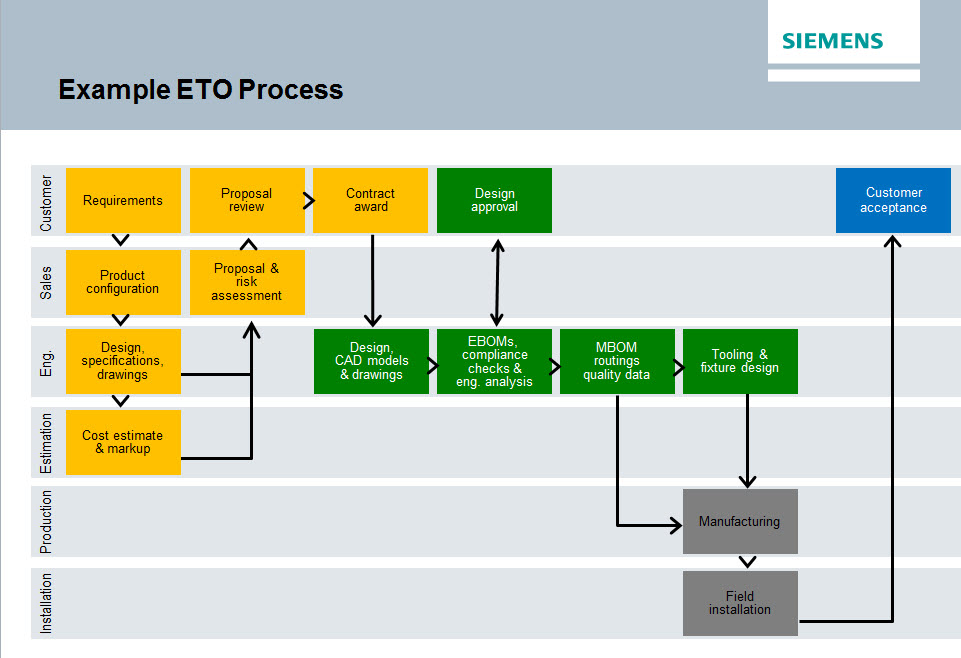

As the name implies, Engineer to Order (ETO) products require the execution of engineering activities to complete each order. The product design for each order is uniquely tailored to the customer’s specification, including the development of order specific product content like Bills of Material, CAD models, drawings, and manufacturing work instructions. ETO products also require engineering execution during the sales proposal process in order to develop the solution to propose. Consider a commercial pasteurizer that is being purchased for a new food processing plant. The customer provides functional requirements such as the attributes of the foods to be processed (e.g. chicken noodle soup), the required capacity (10,000 liters/hour), the inlet and outlet temperatures, the pasteurization temperature, the available fluid temperatures at the plant for heating and cooling, and even the footprint the equipment is required to fit into. Given all the different types of food and beverage products in the world, and the uniqueness of each food processing plant, it would be impractical to pre-engineer all of the potential variants of this product, or even to pre-engineer all the parts along with their part usage rules, so that the product could be configured to order. Therefore, engineering must get involved to transform each customer’s requirements into a design that meets the supplied specification. And that engineering must occur up front in the sales process so that the sales team can prepare a proposal that clearly articulates the solution being proposed.

ETO products can be found in just about every industry. Other examples of Engineer to Order products include power plant boilers, electrical switchgear, commercial HVAC equipment, industrial cranes, and specialty vehicles like fire trucks.In fact, the desire to offer customized, ETO products is on the rise. In a recent survey of ETO companies by Tech Clarity, Driving Engineer-to-Order Differentiation and Profitability, nearly 60% of the respondents said that they expect the amount of product customization they offer will increase over the next 5 years.

Let’s look at some of the complexities that ETO products introduce into the sales process. Because the product has not yet been fully engineered, the costs are unknown, the lead times are unknown, and detailed product data about the solution, such as performance data and drawings, are unknown. Virtually everything required to deliver a proposal is unavailable when a RFP arrives. Yet the clock is ticking on the RFP deadline. Engineering must therefore get involved to transform the customer requirements into enough of a solution so that cost, lead time, and risk can be accurately assessed. That engineering creates a bottleneck to getting a proposal out the door and winning the business. If there is insufficient time to develop a detailed enough design within the allowable proposal response time, then companies must estimate based on rules of thumb or do take offs from previous jobs. Such estimating can be misleading and often introduces guesswork which can erode margins. To offset the risk of margin erosion, companies typically place a contingency on the price and lead time quoted. However, if you put too much contingency on the price and/or lead time, you can price yourself out of the job. Not enough and you may not realize the profit margin on the job. This contingency paradox becomes a high stakes game of educated guess when dealing with high cost capital equipment.

But what if you could quickly engineer a product to customer specification? What if you could rapidly transform a customer’s requirements into a detailed design and associated manufacturing plan that allowed for an accurate, bottoms-up cost and schedule roll-up? And what if you could automatically generate a proposal including all the required product content, such as the technical data, 3D visualizations, sales drawings, and industry/regulatory compliance data. It should be easy to see that you could take an enormous amount of lead time and cost out the process while at the same time increasing accuracy, ultimately helping you win more business and with higher margins.

This is exactly what Siemens PLM’s Rulestream engineer-to-order product enables ETO companies to achieve. Rulestream allows them to capture the engineering rules and heuristics that they use every day to design their products.It further allows them to use those rules to automatically generate a new design to customer specification, complete with all the relevant product content. It provides out-of-the-box integrations to authoring tools such as CAD (including NX, Solid Edge, Creo, SolidWorks and AutoCAD) and Microsoft Office. It also allows them to configure a role specific application for sales proposal automation and order engineering processes.It ultimately allows them to take this complex, long lead time ETO process and make it execute with nearly the same speed and precision as a more configurable product.

For example, Babcock & Wilcox Power Generation (B&W) was able to achieve an 80% reduction in proposal lead time for some products after implementing Rulestream, while at the same time increasing the accuracy of their bids. They have also seen a significant reduction in order engineering lead time for those products, as well as an improvement in cost/schedule estimation. B&W designs, manufactures, and constructs large fossil fuel power plant equipment such as boilers and the downstream environmental equipment. Most of their products are complex and ETO. Hear what Babcock& Wilcox has to say about the business results they realized from automating their ETO processes.

So how does Rulestream fit into the product configuration vision with Teamcenter? There is a broad continuum of product variability that our products must support.ETO is one aspect of that continuum. You may be following our series “Beyond Product Configurator Software: Total Variability Management” where my colleagues have been exploring many aspects of the configurator strategy. We believe that companies having a broad portfolio of products, including Configure to Order and Engineer to Order, will benefit from leveraging the configurator capabilities of Teamcenter and Rulestream. Our vision is to have an integrated solution that spans the entire continuum of product variability, from standard products through engineered to order products, giving our customers an unprecedented degree of flexibility when it comes to implementing a product configuration strategy for their product portfolio.

Like I said in the opening paragraph, timing is everything.We think the timing is right for this vision. We’ll drill down into this topic in more detail in an upcoming blog, so stay tuned.

Other discussions in this series include:

Beyond Product Configurator Software: Total Variability Management

Configurator for Product Management and Planning

Configurator for Engineering and Manufacturing

Configurator for Enabling Customer Choice