Teamcenter Product Cost Management | What’s New in Version 9.1?

With the enhancements in Teamcenter Product Cost Management version 9.1, we support our customers in their product and manufacturing cost reduction initiatives. Customers can carry out calculation processes with optimal flexibility and thus to exploit the innovation potential. They can also closely monitor investments and enhance planning.

Accurate and timely precise should-costing

We continuously update the knowledge database, to support cost engineers in should-cost calculations. This serves as a competitive advantage in supplier negotiations by revealing facts about the manufacturing costs.

Production site: We extended the research methodology with specific region-clusters to focus on important economic regions to further improve the data quality. We tripled the number of data sources for wages and salaries, using both country-specific institutes such as chambers of commerce and global statistical institutes, as well we enhanced white-collar wages. We optimized the process by extending the validation methodology of wage and country data by implementing market information for strategically important production sites such as China, Brazil, Poland, Czech Republic, Argentina, Hungary, etc.

For the first time, we deliver natural gas prices for 30 European countries, which are now used and charged as energy consumption values in the machine hourly rate.

Machine data: We continuously add new technologies to the machine database and replace technologically old machines with the latest generation, to be economically and ecologically up to date. All new machines are equipped with a higher standard of additional equipment for the markets EMEA, Asia Pacific, and America.

Substance and material data: The substance and material data base were enhanced. Through a new cooperation partner, we provide our customers with the latest, most popular tool steel prices per kilogram for the German, EMEA, America, and the Asia Pacific markets. This enables our customers to achieve higher quality calculations in the application and the results.

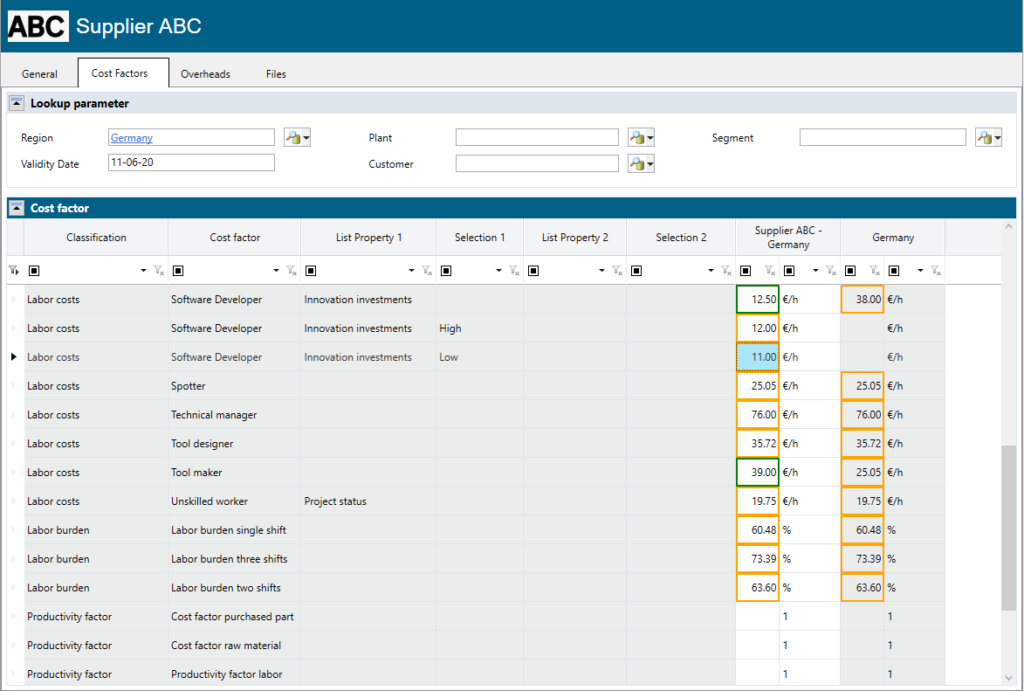

Improved usability for handling supplier-specific cost factors

Cost engineers can analyze and process data much more efficiently in negotiations and in the daily operations:

- Fast access to supplier-specific reference data during negotiations

- Easy comparison between supplier-specific and benchmark reference data

- Easy update of supplier-specific cost factors and overheads

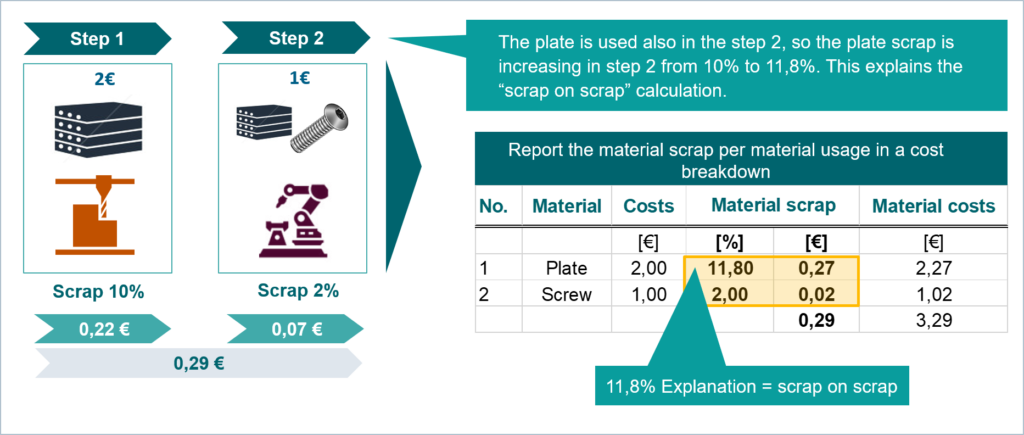

Enhanced material scrap calculation to better support integrations with common cost breakdowns

For OEMs and suppliers, it is important to show and report material scrap per material usage. For example, both want to import and export cost breakdown Excel sheets with material scrap per material usage. Within the new version the material scrap per material usage can be displayed in the UI. With the new update it is also possible to report the material scrap per material usage, for example in the calculation report or in a cost breakdown.

Material scrap depends on where a material is used in the production flow. Therefore, it is important to display the material scrap for each material consumed by a manufacturing step and based on the manufacturing sequence.

In this illustration, you see that the scrap costs of the plate are not 10 percent based only on the first manufacturing step. Considering that the second manufacturing step also consumes the plate with a respective scrap rate of 2 percent, the real scrap rate for the plate is 11.80 percent, since it is used by two manufacturing steps with different scrap rates.

Reuse company knowledge and the calculation process by integrations and gateways

Product Cost Management 9.1 provides the ability to search and import product structures from Teamcenter Manufacturing Process Planning into Teamcenter Product Cost Management to reuse company knowledge and speed-up the quotation calculation process. For any other enterprise applications, we also enable our customers to integrate with these by leveraging the new Teamcenter Product Cost Management gateway for Enterprise Applications by reusing company knowledge to speed-up the calculation process.

Increased flexibility and accuracy of quotation calculations for tool-makers

Tool-makers need to replicate an accurate digital twin of their tool shop including work centers with machines to calculate realistic quotations. With the new version, tool-makers can adjust cycle times of all manufacturing technologies such as drilling, eroding, milling, turning, etc. to achieve more accuracy in the quotation calculation.

For Teamcenter Tool Costing there is now a possibility to influence the working hours of each work center by configuring a so-called “productivity factor”.

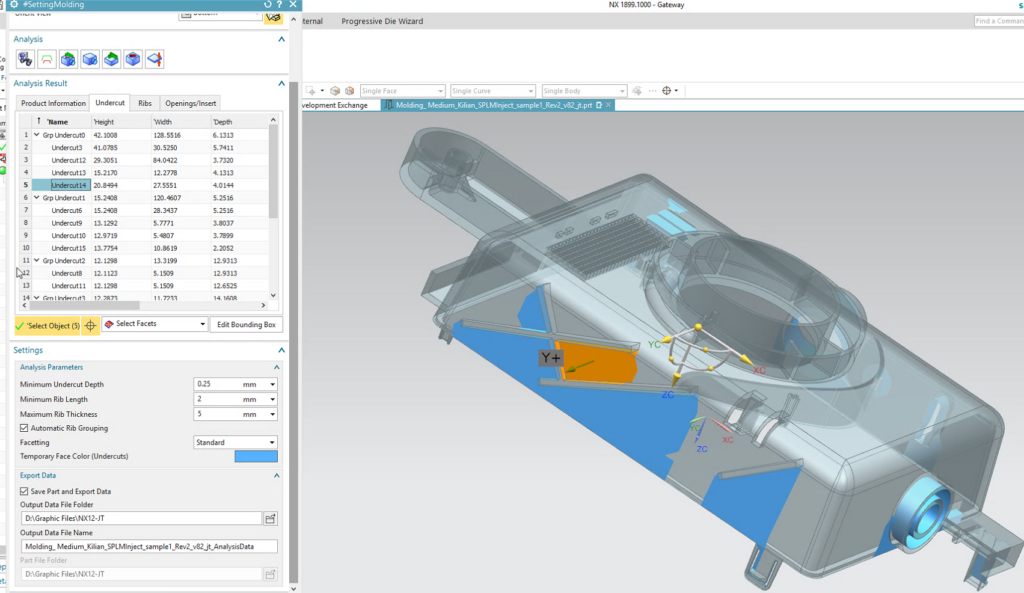

For NX Feature2Cost 1899 we have implemented several improvements and increased the user experience.

- Improved stamping by including features as quantity column, stripper to cuttings and air cushions to drawings

- Increased usability by enabling the rubber band to select multiple features in visualization

- Improved UX of using bounding boxes and extended user settings

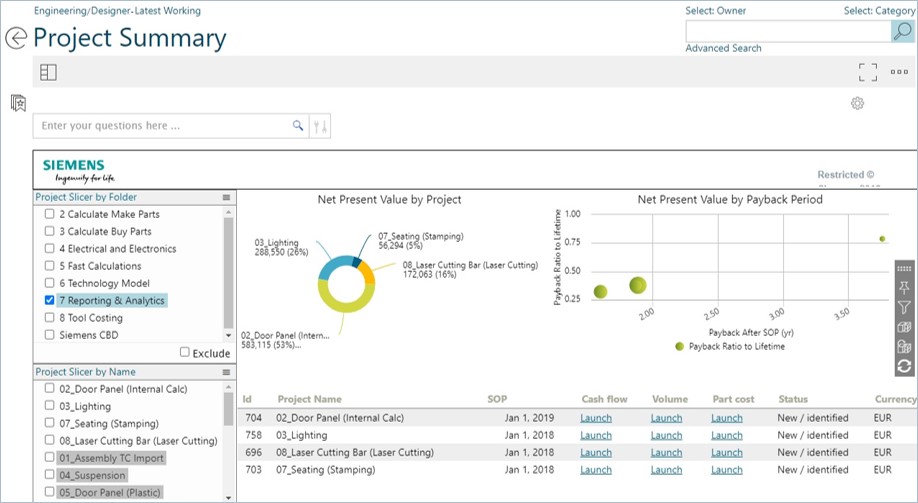

Expose calculation results to downstream reporting systems for more sophisticated slicing and dicing

Expose calculation results to downstream business intelligence systems for more sophisticated slicing and dicing reports such as: display how much DD12 steel will be bought in 2021 grouped by region and supplier and many more macro analytical use cases. Teamcenter Product Cost Management calculation data can be exposed to external systems by storing in a data lake or federated by direct access.

Further improved and new capabilities in Teamcenter Product Cost Management

The user interface of Product Cost Management is updated to better align with the Siemens theme. Additionally, we have improved the overall UI by the following:

- Faster eye scanning by using simple colors aligned with Siemens style

- Better readability by adjusting color ratios and font sizes

- Improved usability by relocating tabs inside the document

The new Web API which accompanies each server installation of Teamcenter Product Cost Management enables out of the box integration for downstream and upstream systems. It allows for programming language independent connection and -in future- will enable various functionalities to transfer data in and out Teamcenter Product Cost Management.

The first commercially available part of this API is exposing calculation results, which enables for connecting the Teamcenter Product Cost Management results into Business intelligence systems for further evaluation. Calculation import is also supported.

With the new version, customers can analyze and process data much more efficiently, calculate smarter, achieve further cost transparency, and realize greater profitability.

Learn more about Teamcenter Product Cost Management version 9.1.