Cost Structure Analysis | Siemens

Learn how MANN+HUMMEL found success with Siemens cost structure analysis by supporting global sourcing strategies. Analyze your own costing structure today!

Why does product cost management play an increasing role in sustaining profitability and competitiveness in the automotive supplier industry? The subject of global sourcing is still a major challenge for medium-sized automotive suppliers. Today, it is necessary to produce and supply in many different local markets in order to remain competitive in price. OEMs increasingly rely on suppliers who are able to supply to the OEMs production facilities worldwide.

In addition to that, modules and components are becoming progressively more complex. Automobile manufacturers now outsource more value-added activities to their suppliers, and delegate more knowledge, than ever before. Reasons for global sourcing range from cost savings in production to access to new markets and availability of specific technologies. What does this all mean for the supplier and his procurement department?

Because of global sourcing strategies, the number of potential suppliers is rapidly expanding. Analysis of international procurement markets to identify suitable suppliers and their potential for innovation and technology is much more complex than with a national procurement policy. This complexity in the supply chain has had a significant influence on purchasing as well as on supplier management. Traditional purchasing tasks will be even more challenging when companies decide to move towards a global sourcing strategy. Complexities rises in a lot of processes like make-or buy analysis, product and cost structure management, as well as judging on supplier performance and product quality to name just a few. The consequences of this are the evolution of the procurement function to both product and process-related range of tasks.

For a strategic sourcing initiative to be successful, procurement professionals must expand their prospective supplier base globally. They must critically review the products they buy and open their business to increased competition. They must evaluate cost savings along with the level of quality and service provided by all potential suppliers. Most procurement professionals already use product cost management tools to determine target costs, do cost analysis, benchmark, and bottom-up should cost calculation. These tools deliver transparency and insight about the existing material groups and cost structure details of more complex products. These capabilities help in developing initiatives, identifying cost savings, and improving the performance potential and cooperation with strategic suppliers.

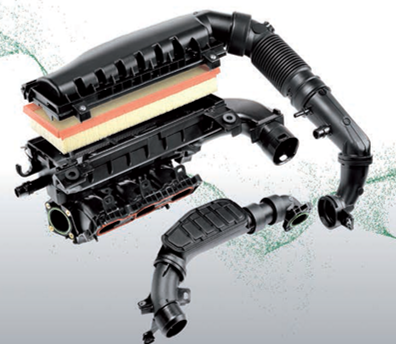

Another major challenge for the automotive supplier industry is the constant need to deal with price and margin pressure within every project. For example, the German automotive supplier MANN+HUMMEL manufactures liquid and air filtration systems, air intake systems and cabin filters for the automotive industry. The company develops, coordinates and delivers complete solutions for leading car manufacturers, including highly complex air intake systems for the BMW i8 and Cadillac CTS hybrid sports cars, intake manifolds for GM diesel engines, oil filters for Audi engines, charge air resonators for Volvo engines, and fuel filters for Mercedes-Benz® diesel vehicles.

MANN+HUMMEL uses global sourcing strategies to foster profitability and competitiveness by optimizing material costs and structuring supplier management and development. In supplier management and procurement, MANN+HUMMEL sets priorities for consistent development and implementation of specific supplier portfolio and commodities group strategies. The goal in both areas is to identify potential savings and, at the same time, demonstrate the steps necessary to achieve objectives.

Read more about the benefits of product cost management and how MANN+HUMMEL achieves cost reduction success within procurement. and check out other cost management articles.