SHL Medical goes paperless with Siemens’ manufacturing planning and simulation solutions [VIDEO]

SHL Medical, the leading provider of drug delivery solutions, uses Teamcenter Easy Plan and Tecnomatix Plant Simulation to connect engineering, manufacturing, and enterprise systems into a fully integrated digital workflow.

Millions of patients with chronic conditions depend on reliable self-injection devices for lifelong treatment. SHL Medical designs and manufactures autoinjectors, pen injectors, and large-volume injection systems from its headquarters in Zug, Switzerland.

Operating under stringent medical device and pharmaceutical regulations, SHL Medical must deliver consistent quality while scaling production. Using Siemens’ Teamcenter Easy Plan and Tecnomatix Plant Simulation, SHL Medical connected engineering and manufacturing, centralized production data, and virtually validated manufacturing processes before production began.

Here’s how SHL Medical tackled these challenges and transformed its operations.

Centralizing manufacturing data with Teamcenter Easy Plan

The old paper-driven approach could no longer keep up with demand. SHL Medical needed a smarter, faster way to link engineering and manufacturing digitally. Aligning teams, workflows, and data manually wasn’t enough, centralizing all critical manufacturing information became the first step toward a connected, efficient operation.

Fabian Hoefer, Global Business Process Owner PLM at SHL Medical, explains: “Easy Plan and Teamcenter are a crucial part of this journey.”

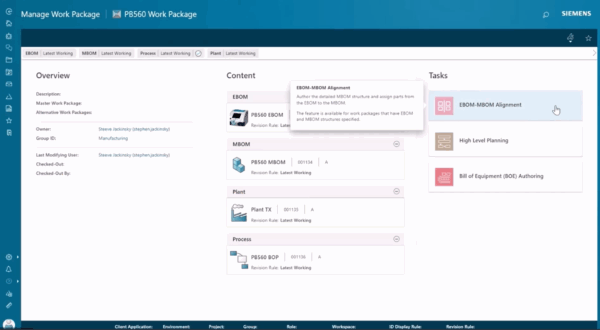

With Teamcenter Easy Plan, SHL Medical now has all critical manufacturing information in a single global system, including:

- Work instructions

- Work plans

- Routings

- BOMs (Bill of Materials)

- BOPs (Bill of Process)

This data flows seamlessly to SAP and MES (Manufacturing Execution System), creating a central knowledge hub that ensures efficient knowledge transfer across teams and consistent processes for every product.

Closed-Loop Manufacturing: Connecting ERP, MES, and PLM

Digital manufacturing at SHL Medical relies on a closed-loop approach, linking the “golden triangle” of PLM, MES, and ERP. This integration gives full visibility from engineering to production, enabling efficient workflows, knowledge transfer, and scalable operations.

It helps SHL Medical proactively identify bottlenecks, reduce errors, and maintain consistent quality across the production line.

“What I’m really looking forward to is that we can use this digitization to get to the core of our operations. For me, closed-loop manufacturing with the magic triangle is the core part. We have a connection between PLM, MES and SAP that we are using the strength of all of these systems, and we are talking about people, process, system and data.”

Fabian Hoefer, Global Business Process Owner, PLM, SHL Medical

Simulation to get it right the first time

Effective manufacturing planning goes beyond connecting engineering and manufacturing or digitalizing workflows. It requires planning, simulation and validation to ensure processes are accurate and efficient from start to finish before production begins.

Tecnomatix Plant Simulation gives SHL Medical a complete view of factory operations—from incoming supplies to finished products.

SHL Medical tests different scenarios virtually before anything reaches the shop floor, identifying potential bottlenecks, preventing costly issues, and keeping production running efficiently. The aimed to overcome these limitations by using Plant Simulation to demonstrate how automation increases productivity and better controls inventory within the medical technology industry. The goal was to create a deeply integrated process, seamlessly connecting various autoinjector production areas.

This end-to-end simulation ensures workflows run smoothly and allows SHL Medical to confidently meet growing demand, efficiently and reliably.

“Tecnomatix Plant Simulation is helping us to see how we run our manufacturing”

Fabian Hoefer, Global Business Process Owner, PLM, SHL Medical

When People, Processes, Systems, Partnerships and Data come together

At SHL Medical, true success comes from bringing people, processes, systems, and data together into one connected ecosystem. With Teamcenter Easy Plan and Tecnomatix Plant Simulation, they can plan, simulate, and execute operations with confidence—catching issues before they reach the shop floor and streamlining workflows across the organization.

This integrated approach is what allows SHL Medical to scale efficiently and ramp up manufacturing, producing auto-injectors that patients can rely on to safely administer their medication.

“Our partnership with Avasis is a very strong one. They give us the input what we need from a medical device perspective. So we can partner, we can discuss these ideas, we can look for the best solutions.”

Fabian Hoefer, Global Business Process Owner, PLM, SHL Medical

By digitizing planning, simulation, and execution, SHL Medical demonstrates how medical device manufacturers can meet rising demand without compromising quality.

The journey from paper-driven workflows to a fully connected digital ecosystem highlights the future of medical manufacturing—where operations are smarter, faster, and more reliable, ultimately benefiting patients worldwide.