Webinar replay: Routing pipes, tubes and hoses around your assemblies

Routing pipes and tubes around 3D assemblies is simplified using Solid Edge XpresRoute capabilities.

Routing pipes and tubes around 3D assemblies is simplified using Solid Edge XpresRoute capabilities.

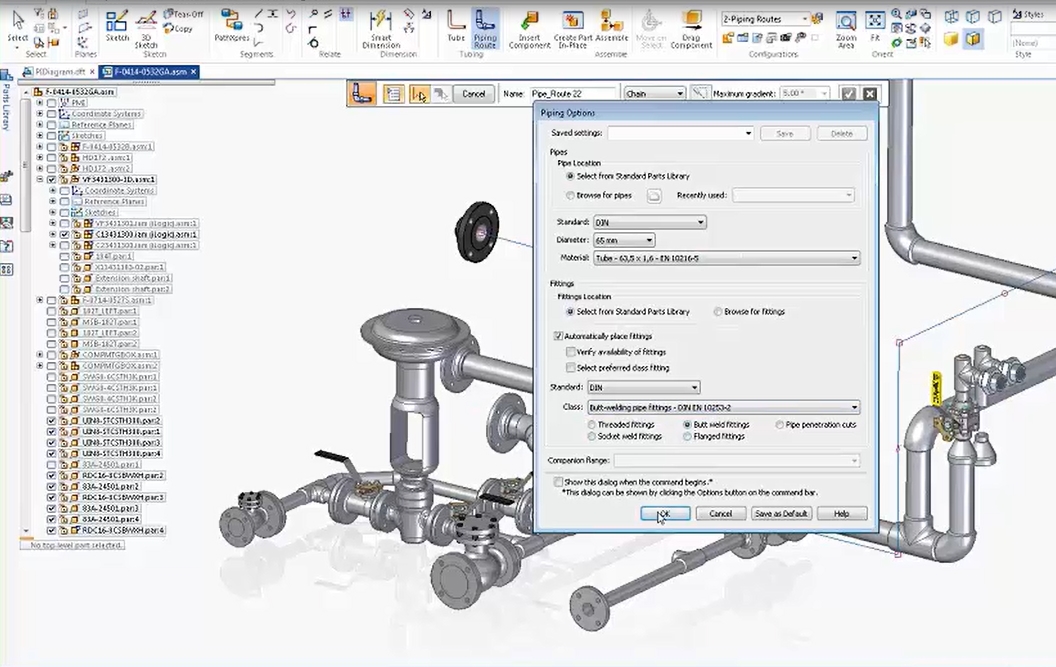

A new webinar replay is available that includes an excellent demonstration of how to include pipes, tubes and flexible hoses into your assemblies. Many mechanical assemblies and of course process plants require pipes, tubes and hoses to transport fluids and gases around the plant or assembly. Solid Edge has excellent tools to design efficient pipe and tube runs to meet these requirements.

The webinar starts with an introduction to digital transformation and how the Solid Edge portfolio helps manufacturers create digital twins of their product designs, and use these to improve the speed and overall performance of their product development. It quickly moves into a demonstration of creating 2D P&ID diagrams, designing pipe runs in 3D, and also adding tubing and flexible hoses to your designs.

Some nice features in the add-on XpresRoute module I noted where the provision of standard libraries of piping and piping components that meet ISO, DIN and ANSI standards, and the ability to add your own or catalog components to these libraries. (XpresRoute is included with Solid Edge Premium and available as an add-on for Solid Edge Foundation and Classic). For tubes there is a nice PathXpres feature that presents different options for connecting two points across an assembly, and a bend table and cut lengths are presented for your chosen routing.

For flexible hoses you can specify control points to influence the 3D path of the hose, and you can specify the hose to be a certain length so you can use off-the-shelf hoses.

Finally you can document your piping design ensuring that manufacturing has the information they need to manufacture and assembly the piping accurately, minimizing errors in the final assembly process.

You can also check out this knowledge base article for some more illustrations of these capabilities.

Libraries of standard pipe sections and pipe components are available to ISO, DIN and ANSI standards.

Libraries of standard pipe sections and pipe components are available to ISO, DIN and ANSI standards.

This webinar in just one in a series of 15 webinars covering many of the capabilites of the Solid Edge Portfolio, register here to watch the replay of this webinar and you will get access to all 15 webinar replays!

Creating & Managing Large Assemblies Made Easy in Solid Edge

As designs become more complex, the number of parts in an assembly often grows. Solid Edge capabilities for assembly modeling and management helps you quickly and easily create and manage even the largest assemblies, without lags or crashes. Create exact representations of all components—including tubes, pipes, wires, weldments and sheet metal—in a complete digital mockup that allows for more accurate design and analysis. Solid Edge helps you quickly detect and fix clash and interference issues, generate assembly instructions, and conduct customer reviews—reducing the need for costly prototypes.

Comments