Webinar: Modular Plant Design in Solid Edge

Designing and developing plants today is no easy task. Each project is custom. Yet, there seems to be a high amount of repetitive work. What if there was a way to reuse existing designs in the interest of time, while still making each design unique?

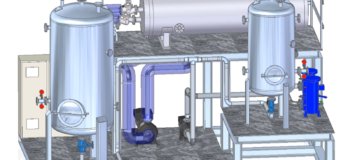

Well, some companies are doing exactly that. Modular Plant Design capabilities in Solid Edge allow you to find the right mix of configuring modular assemblies and engineering for that last bit of the project that’s still new to the world. When done right, modular plant design allows companies to respond quickly and accurately to customer requests for quotation (RFQ), accelerate their design process, please their customers with unique designs, and apply best practices borne from small numbers of highly experienced industry experts.

In our latest on-demand webinar, you’ll learn from Chad Jackson (Lifecycle Insights) and Michael Mooney (Smap3D Plant Design) about how to respond faster and more accurately to RFQs, streamline your product development process, and control product costs. Register to watch this free webinar on-demand today.

Modular Plant Design in Solid Edge

From rudimentary 2D pipe planning to full-scale 3D piping systems, modular plant design solutions in Solid Edge help to streamline your workflow processes. Linked 3D piping, support for piping and instrumentation diagrams (P&ID) and Isogen® output ensure that your products are designed right—the first time, and every time. These software modules also allow you to easily capture design intent/logic in a 2D schematic, then develop 2D P&IDs into a comprehensive 3D model of a process plant.

Solid Edge combines three core modular plant design solutions that allow for fast, easy planning of complex piping systems and plant designs:

- Solid Edge XpresRoute

- Solid Edge P&ID Design

- Solid Edge Piping Design

Below, we highlight some of the key benefits of these three powerful solutions.

Solid Edge XpresRoute

Solid Edge XpresRoute streamlines the design of mechanical routed systems in a 3D environment, creating pipe and tube routes for the most efficient design.

After the design is complete, Solid Edge XpresRoute continues to boost productivity and reduce costs by automatically creating detailed reports, BOMs and other valuable purchasing and manufacturing information.

Solid Edge P&ID Design

Solid Edge P&ID Design provides 2D flow diagram and symbol support to create P&IDs, which are crucial for meeting company and international quality standards.

Solid Edge P&ID Design supports ANSI/ISA, DIN, and EN ISO standards, and it connects seamlessly to Solid Edge Piping Design capabilities, in which its definitions control automated 3D pipeline creation. All features that are defined in P&ID can be easily placed into a 3D model, making Solid Edge a truly complete modular plant design solution.

Solid Edge Piping Design

Solid Edge Piping Design provides you with automated 3D piping design with comprehensive 3D part libraries and fully automated ISOGEN® output, via PDF format, for plant design.

Tubes and hoses of the same length in different assemblies—even if they are flexed differently—maintain the same BOM number, reducing erroneous manufacturing and ordering downstream. Solid Edge Piping Design software includes functionality that allows you to speed up packaging design. In addition, it also includes enhanced 3D piping sketch functionality that allows even the most inexperienced user to easily create 3D sketches. Register for the on-demand webinar to learn more.

For additional information about Solid Edge solutions for modular plant design, you can visit our website or simply download a free trial of Solid Edge to give our solutions a try for yourself.

Comments