Using CAMWorks for Solid Edge

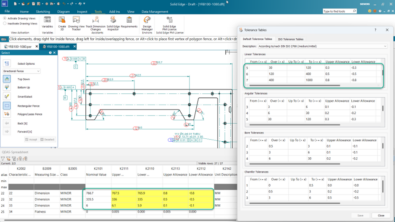

I want to use this post to address the basic operation of CAMWorks for Solid Edge. At its core the product uses built-in intelligence to recognize several different types of prismatic features and then uses pre-defined strategies to machine those features. Recognizable features include: Pockets (Open, Closed, Circular, Rectangular and Irregular-shaped), Slots (several varities), and Holes (also several varities) and Bosses.

To recognize these features, CAMWorks examines the geometry, NOT the feature list (aka History Tree). This is important, especially when dealing with imported solid bodies where the feature list consists of one item – the copied body. It is also important when the model was built using Synchronous Technology, because the feature list there is very abbreviated.

Once the feature list is built, CAMWorks reaches into the Technology database (TechDB) to assign machining strategies. There are default strategies that come shipped with the software, but all experienced users tell me that some time must be spent customizing the TechDB to their style of machining. This makes sense to me – as a former post processor builder, I always ran into situations where new customers would want a proved-out post processor changed to match their shop’s style.

After the TechDB builds the operation list, the rest of the work is very similar to other CAM systems: generate the tool paths, simulate the cutting motion, and post process.

After the TechDB builds the operation list, the rest of the work is very similar to other CAM systems: generate the tool paths, simulate the cutting motion, and post process.

The following video demonstrates how CAMWorks for Solid Edge works on a simple assembly model. I am using the out-of-the-box TechDB, so no fancy demo tricks here.

Jim has a Master’s degree in Business Administration from the University of Central Missouri. He has over 30 years of experience in the manufacturing industry, and over 25 years of experience in the CAD/CAM field. He serves as Field Support for Siemens PLM CAM products. Prior to his current role, he held stints as CNC Programmer, CAD/CAM Department Manager, CAD/CAM instructor, and Project Coordinator for Siemens PLM CAM software development. He says “Congratulations!” to NCAA DII Men’s Basketball Champions UCM Mules.

Jim has a Master’s degree in Business Administration from the University of Central Missouri. He has over 30 years of experience in the manufacturing industry, and over 25 years of experience in the CAD/CAM field. He serves as Field Support for Siemens PLM CAM products. Prior to his current role, he held stints as CNC Programmer, CAD/CAM Department Manager, CAD/CAM instructor, and Project Coordinator for Siemens PLM CAM software development. He says “Congratulations!” to NCAA DII Men’s Basketball Champions UCM Mules.

Comments