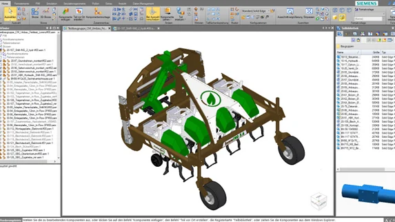

Start-up UAV manufacturer uses Solid Edge, helps farmers maximize crop yields

Concept design of a Skybridge UAV in Solid EdgeIan Henderson, COO of Skybridge UAS spoke at the recent Solid Edge ST9 event in Orlando about how they have been using Solid Edge to design unmanned aerial vehicles that help farmers optimize their crop yields. The UAVs use a variety of sensors to collect data about soil conditions and crop growth in a very cost effective way.

Concept design of a Skybridge UAV in Solid EdgeIan Henderson, COO of Skybridge UAS spoke at the recent Solid Edge ST9 event in Orlando about how they have been using Solid Edge to design unmanned aerial vehicles that help farmers optimize their crop yields. The UAVs use a variety of sensors to collect data about soil conditions and crop growth in a very cost effective way.

Skybridge is an example of a start-up manufacturing company that doesn’t yet have a significant income stream, but needs to quickly complete a large amount of both concept and detail design work. According to Ian “We needed to have a design tool that would fit a fixed income company that needs to do a lot of engineering work to develop an aircraft.” They found that using monthly subscriptions for their Solid Edge licenses met their needs for flexibility and low cost while delivering powerful design capabilities. Using Solid Edge, Skybridge is designing UAVs that can stay aloft from morning to night while carrying over 25 pounds of sensors, enabling cost effective data collection over multiple farms in a single day.

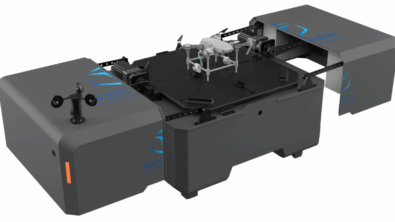

Skybridge UAVs gather data using advanced sensors to monitor soil and crop conditions

Skybridge UAVs gather data using advanced sensors to monitor soil and crop conditions

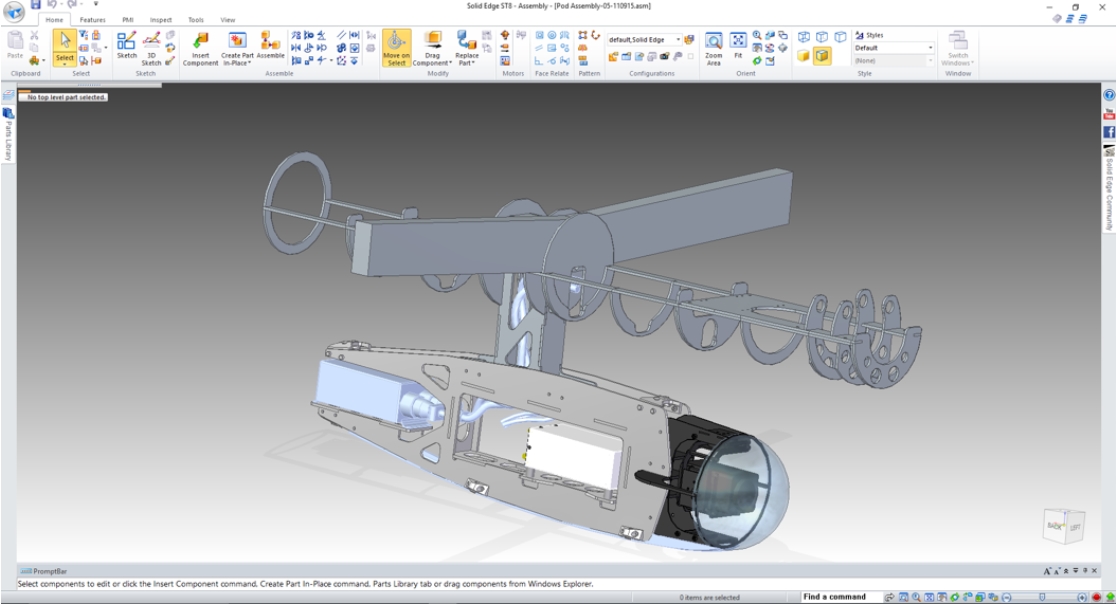

Skybridge UAVs feature detachable pods that can carry a variety of sensorsSkybridge has also found that synchronous technology delivers significant benefits. “A single part changed inside the structure of an aircraft changes all of the structural members around it…with synchronous technology we are able to make those changes very rapidly.” If you are new to synchronous technology we have an entertaining new video that explains this exciting approach to 3D design.

Skybridge UAVs feature detachable pods that can carry a variety of sensorsSkybridge has also found that synchronous technology delivers significant benefits. “A single part changed inside the structure of an aircraft changes all of the structural members around it…with synchronous technology we are able to make those changes very rapidly.” If you are new to synchronous technology we have an entertaining new video that explains this exciting approach to 3D design.

In the video below Ian Henderson talks about Skybridge, their selection of Solid Edge for 3D CAD and the benefits they are seeing from synchronous technology. Let us know what you think about the Skybridge story, or your own experience with Solid Edge subscriptions and synchronous technology!