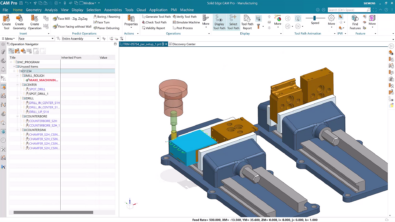

Mill-Turn Capability in CAMWorks for Solid Edge

CAMWorks for Solid Edge not only supports traditional turning, but it also supports mill-turn machines (aka multi-function machines). A typical mill-turn machine can perform traditional turning functions like turning on the Outer Diameter (OD) and Inner Diameter (ID), as well as centerline drilling, grooving (face, OD, ID), threading, and boring.

So is it a mill-turn? To define a mill-turn, I use this minimum criteria:

- It can perform lathe functions (the part spins and the cutting tool is stationary)

- It must be able to rotate and lock the spindle axis to a specific angle. For most mill-turns, this capability is identified as the C-axis

- It must have live tooling capability on the turret (so that milling/drilling can take place in the X-axis

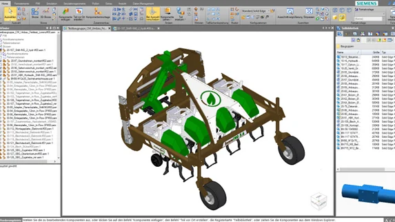

Here is a video of a mill-turn machine that meets the above requirements. There are many other capabilities that modern mill-turns, but these are the minimum.

So, how does CAMWorks for Solid Edge perform at NC programming of this style mill-turn? Very nicely. Watch the video I created using this product.

Comments