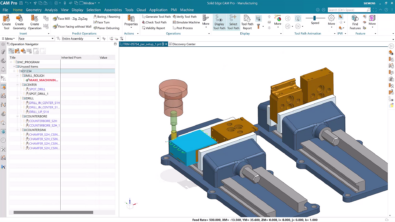

Machining Multiple Setups with CAMWorks for Solid Edge

Job shops like it when they get to produce more than one of the same item. It lets them amortize their setup costs over several parts, rather than just one. They REALLY like it when they can have multiple parts on the table being machined at the same time. Obviously, a key factor in doing this is the ratio of the part size to the machine in question.

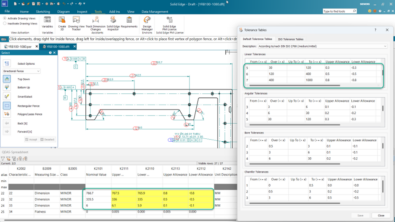

Another nice feature is that an edit to operation applies to all components on the table – you don’t have to remember whether you made the edits to all the different components or not.

Finally, with its speedy-fast feature recognition and tool path engine, CAMWorks for Solid Edge can have that job up and running fast and making you money. Want to see fast? Watch the video below.

Comments