In-Context Editing, Synchronous Style

For those of you who are keeping track of our journey with the pressure washer assembly, we started out by migrating it into Solid Edge from Works. Then we checked out how many of the mates came across, and made some simple motion with the engine. Next we made some edits to migrated parts, removing fillets, pulling features with the steering wheel, and applying dimensions.

For those of you who are keeping track of our journey with the pressure washer assembly, we started out by migrating it into Solid Edge from Works. Then we checked out how many of the mates came across, and made some simple motion with the engine. Next we made some edits to migrated parts, removing fillets, pulling features with the steering wheel, and applying dimensions.

In this installment, we’re going to work through some Synchronous in-context edits, also known as inter-part or top-down assembly editing.

In-context edits in history-based software can be expensive, tedious, error prone, and just overall frustrating. These are the items required when making an in-context relationship between two parts in an assembly in SolidWorks:

- Relationship in the child part that remembers the parent part and the parent assembly

- Relationship in the parent assembly that remembers the parent part and the child part

- All three file names maintained

- Parts cannot move relative to one another

Rebuilds take longer because all parts and assemblies have to be open at the same time and rebuilt together. Tell me with a straight face that this doesn’t sound like a completely awful idea. Ten years ago this was as good as it got, and we kind of reveled in the complexity. But today, our products are complex, so our tools shouldn’t be. Powerful, yes. Complex, no.

Let me first tell you how it is in Synchronous assemblies, then I’ll show you, then you can decide how far you want to throw those installation disks for whatever history-only software you’ve been saddled with.

With Synchronous Technology, working in assemblies, you can edit multiple parts at the same time, or use one part as reference without creating the kind of persistent relationships that bog you down in BrandX. Move the face of one part up to the face of another, edit two aligned pockets in two different parts at the same time, edit the depth of a hole and a pin at the same time by the same amount. If you set up design intent of this sort in BrandX, you wind up with longer rebuilds for your assembly, parts you can’t fully edit without the rest of the assembly, a tangled mess of relationships that other people may not be able to untangle, and parts that may change unexpectedly when you make certain types of edits. Without Synchronous Technology, this kind of change is unnecessarily complicated.

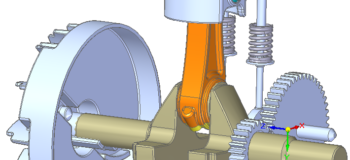

Let’s try one. Back to the motor sub-assembly from the pressure washer. In this video example, we’re going to edit 4 parts at one time. 3 of those part will change symmetrically. This is without any predefined setup.

Changes like this require no setup, no overhead, they are easy to understand, and simple to accomplish. There is no such thing as violating a CAD best practice with this type of change. You start with geometry, and end with geometry. Part of the beauty of synchronous is that you are just working with geometry, not with undecipherable relationships between parts, sketches, faces, features, assemblies and whatnot. This technique’s power comes in part from its simplicity.

Another type of edit would be to match the face of one part with another, or even multiple parts. Let’s have a look at another video demo.

Comments