Cracking the Egg Conveyor Code

Castra Machinebouw is developing agricultural tech for the egg industry with Designcenter Solid Edge finesse.

For decades, poultry farms have relied on conveyor systems originally designed more than 25 years ago. Back then, egg production volumes were far lower than today’s industrial-scale operations. Now, with massive poultry houses collecting millions of eggs annually, these legacy systems are being pushed far beyond their intended limits. Even a seemingly minor breakage rate of one or two percent can cost producers thousands of Euros each year.

Spotting inefficiency as an opportunity

Engineer Heiny Van De Kamp recognized the bottleneck: conveyors that were gentle on eggs, but no longer efficient enough for today’s scale. In 2022, he founded Castra Machinebouw to engineer a smarter, safer conveyor system—one capable of moving tens of thousands of eggs per hour with minimal loss. By combining industry insight with fresh design thinking, Van De Kamp and his startup are helping poultry operations modernize a system that has gone largely unchanged for decades.

A Conveyor Built for Scale

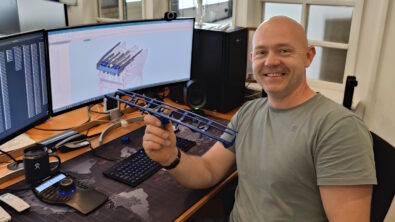

The breakthrough came from rethinking the very mechanism that holds the eggs. Traditional conveyors rely on rigid plastic or steel carriers. Castra’s new design uses injection-molded variable carriers that lift eggs gently from below. This small but crucial change dramatically reduces breakage.

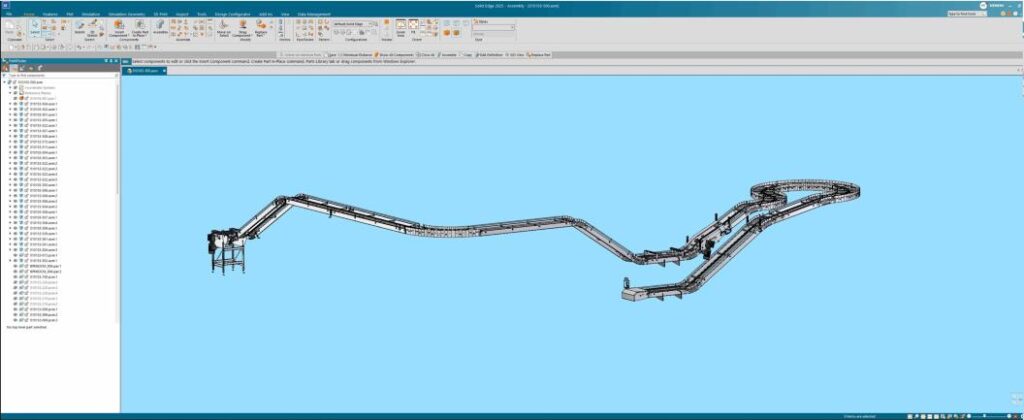

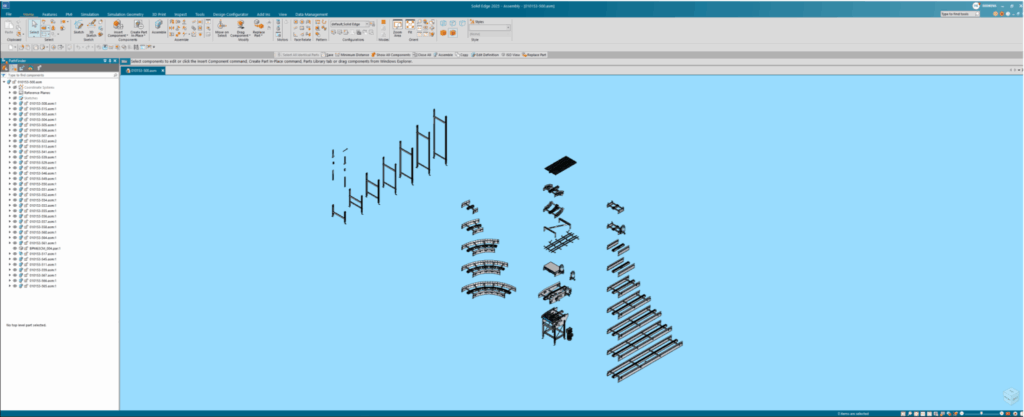

Prototype development wasn’t without setbacks. Early 3D-printed plastics caused friction and demanded oversized motors, which raised costs and reduced efficiency. By shifting to injection-molded materials, Castra improved smoothness and reliability while lowering operational demands. His design also makes the carrier depth variable so that transfers are as calm as possible, while still retaining the strength to manage high volumes. The system is already capable of transporting forty-five thousand eggs per hour, handling inclines and declines up to thirty-five degrees, and covering long distances in modular sections while remaining compact at just half a meter wide.

“With my new egg conveyor, I want to redefine the transport of eggs from poultry house to collecting room for the next 20 years,” Van De Kamp says.

From Concept to Chicken Coop with CAD

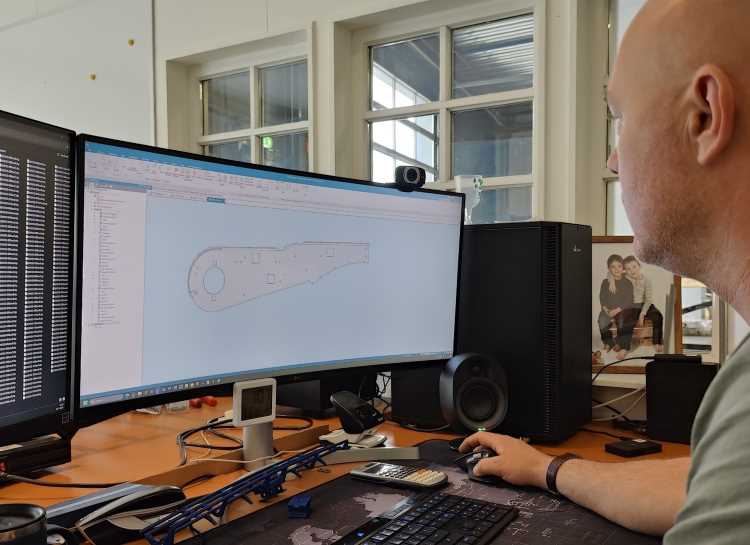

Central to Castra Machinebouw’s success is the usage of Designcenter Solid Edge, a 3D CAD tool provided to Van De Kamp through the Designcenter Solid Edge for Startups program by Siemens. Designcenter Solid Edge’s capabilities allowed him to move quickly from concept to working prototypes, particularly with its powerful sheet-metal features and Synchronous Technology.

“Solid Edge was always a little bit of the underdog,” he reflects. “But I grew up with it, and for me, it’s the best tool for sheet metal.”

Van De Kamp also credits Siemens partner Enginia for support in both accessing and mastering Designcenter Solid Edge—helping Castra turn early sketches into scalable, production-ready designs.

Beyond Eggs: A Versatile Engineering Partner

Castra’s innovation doesn’t stop with poultry. Using Designcenter Solid Edge, the company is also developing highly specialized engineering solutions such as an RF-based sausage-cooking system that reduces processing time and energy use, custom marine sheet-metal projects, and waste upcycling equipment for sustainable industry applications. Across this diverse portfolio, Designcenter Solid Edge helps Castra accelerate development, cut unnecessary steps, and bring designs to market more efficiently—time savings that directly impact the bottom line.

“Sheet metal is essential in my line of work, and Solid Edge is really strong on that point,” Van De Kamp says. The platform’s unified environment makes it possible for him to juggle these varied projects without sacrificing speed or quality.

Scaling Up for the Future

With industry testing already underway, Castra Machinebouw is preparing for the next phase: scaling up. Van De Kamp has built partnerships with sheet-metal and injection-molding specialists, ensuring production capacity is ready once demand accelerates. He envisions Castra evolving from a small startup into a vertically integrated manufacturer, complete with its own facilities and a larger workforce to meet industry needs.

“I have teamed up with a sheet metal worker who has the capacity for large runs, and I have teamed up with an injection mold company, who has the experience, the know-how and the people to scale up. So, everything is set to scale up,” he explains.

The company’s early results are promising, and full-scale testing with industry leaders could mark the turning point for widespread adoption. By addressing a long-overlooked inefficiency in egg handling, Castra Machinebouw is not only helping farms reduce losses but also setting new standards for the industry.

As Castra Machinebouw continues to grow, Designcenter Solid Edge will remain central to its success. The software supports immediate engineering needs while also providing a foundation for future expansion. For Van De Kamp, it has been both a design tool and a strategic advantage—helping him bring a bold vision for egg handling, and beyond, into reality.

👉 Visit Siemens to learn more about the Designcenter Solid Edge for Startups program.