Adaptive Machining in Solid Edge CAM Pro

A few years back, I wrote a 3-part blog post on “The Evolution of Tool Path Design”. If you haven’t read Part 1, Part 2, and Part 3, they are still valid today. Go ahead, I’ll wait.

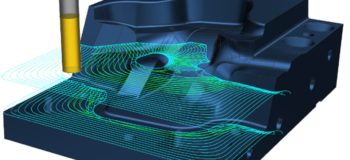

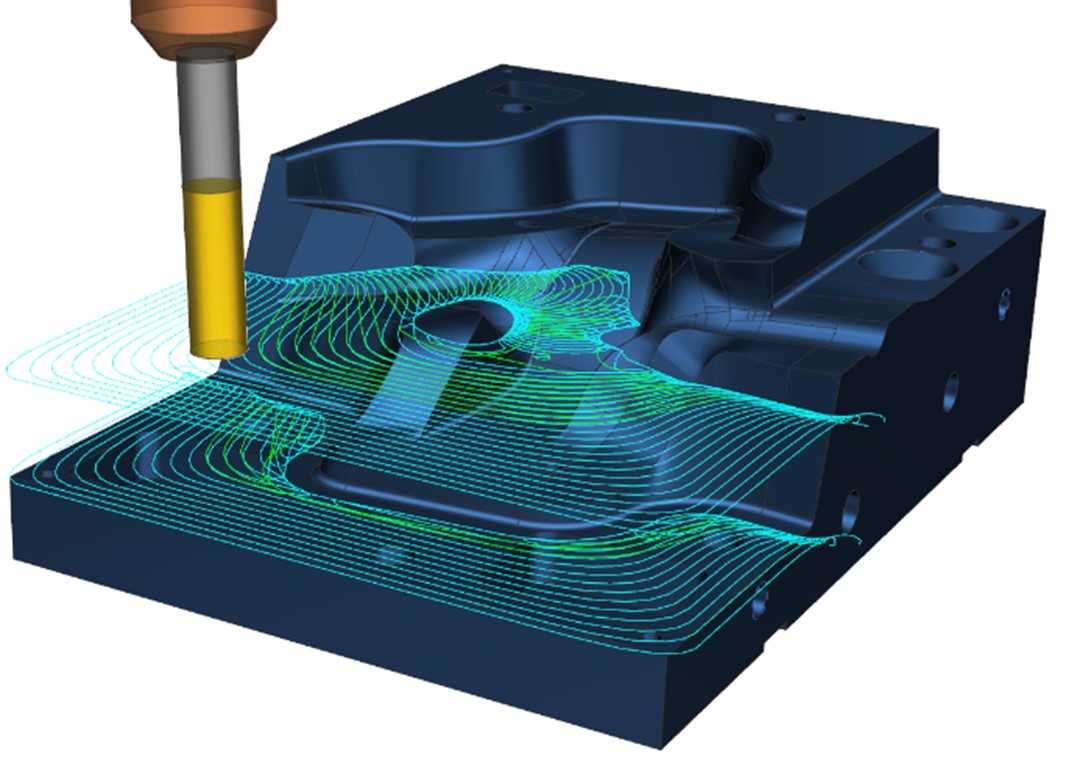

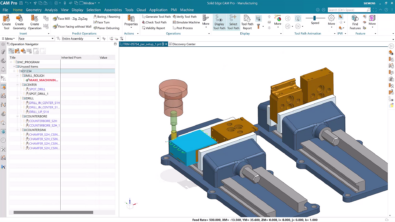

Great, you’re back! Now that you understand how tool path science has advanced over the years, you will be able to see the great benefit of Adaptive Clearance Tool Path now available in Solid Edge CAM Pro. You see, one of the problems we have in milling is that normal cut patterns vary the amount of material that is removed – therefore sometimes the feedrate is too high (stressing and/or breaking the tool), or the feedrate is too low (which takes more time than necessary). Adaptive Clearance solves that by maintaining a consistent chip thickness through varying the stepover and keeping the feedrate constant. If the feedrate is constant, you can run at maximum all the time. If you are machining hard materials, this benefit is very obvious, but it works in all machinable materials.

New in the latest release is “pillar cutting”. The really smart folks in development have figured out how to handle pesky pillars (leftover columns of material). It’s hard to explain, so just watch the video below. In the live-machining portion, when you hear the ‘tink’ of the column snapping off, you could also imagine that as the tool breaking.

Oh, and did I mention if you have a CAM package that includes 3-Axis milling, Adaptive Clearance Tool Path is included at no extra charge? World-class performance and a great value. The Adaptive Clearance Tool Path is a true win-win-win proposal:

- Win – material is removed faster

- Win – cutting tools last longer

- Win – included at no extra charge

If you’re attending IMTS 2018, why not stop by booth 134500, East Building and see us? You can get a live demo of both Solid Edge and Solid Edge CAM Pro. We will also be showing off some live machining.

Comments