Industry Survey Validates Need for ECAD-MCAD Collaboration

A recent report based on a study by the journalistic experts at engineering.com entitled “Research Report: Integrating Electrical and Mechanical Design. Do product teams see value?” validates what we in the software industry have claimed for some time: “Product designers are losing time due to poor integration between their electrical and mechanical design processes.” It’s always nice to be able to see clear data that validates one’s message; however, what’s really important about the study is that it shows how valuable it is for teams to use integrated electrical and mechanical design, with the key word being integrated. A tightly integrated electromechanical solution enables true co-design across disciplines, as the impact of a change can be assessed in both domains during the complete product development process.

A recent report based on a study by the journalistic experts at engineering.com entitled “Research Report: Integrating Electrical and Mechanical Design. Do product teams see value?” validates what we in the software industry have claimed for some time: “Product designers are losing time due to poor integration between their electrical and mechanical design processes.” It’s always nice to be able to see clear data that validates one’s message; however, what’s really important about the study is that it shows how valuable it is for teams to use integrated electrical and mechanical design, with the key word being integrated. A tightly integrated electromechanical solution enables true co-design across disciplines, as the impact of a change can be assessed in both domains during the complete product development process.

Why is this important? Enabling effective collaboration is critical for increasing productivity and ensuring the design achieves first-pass success. Without a coordinated flow, integration has to wait on a physical prototype to be built, which typically doesn’t happen until late in the design cycle. No one wants to go back to the drawing board to fix a simple blown fuse after a prototype has been built.

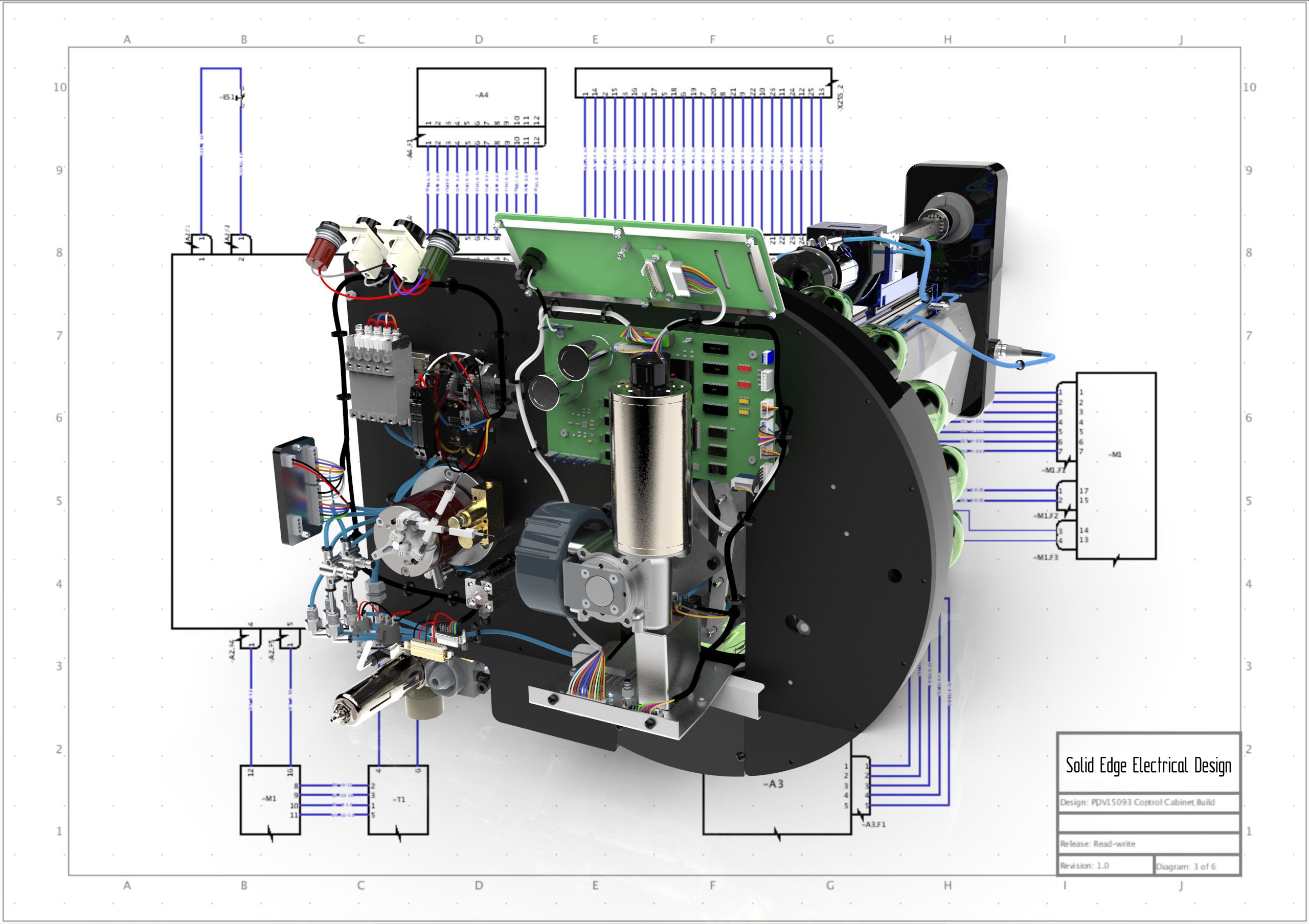

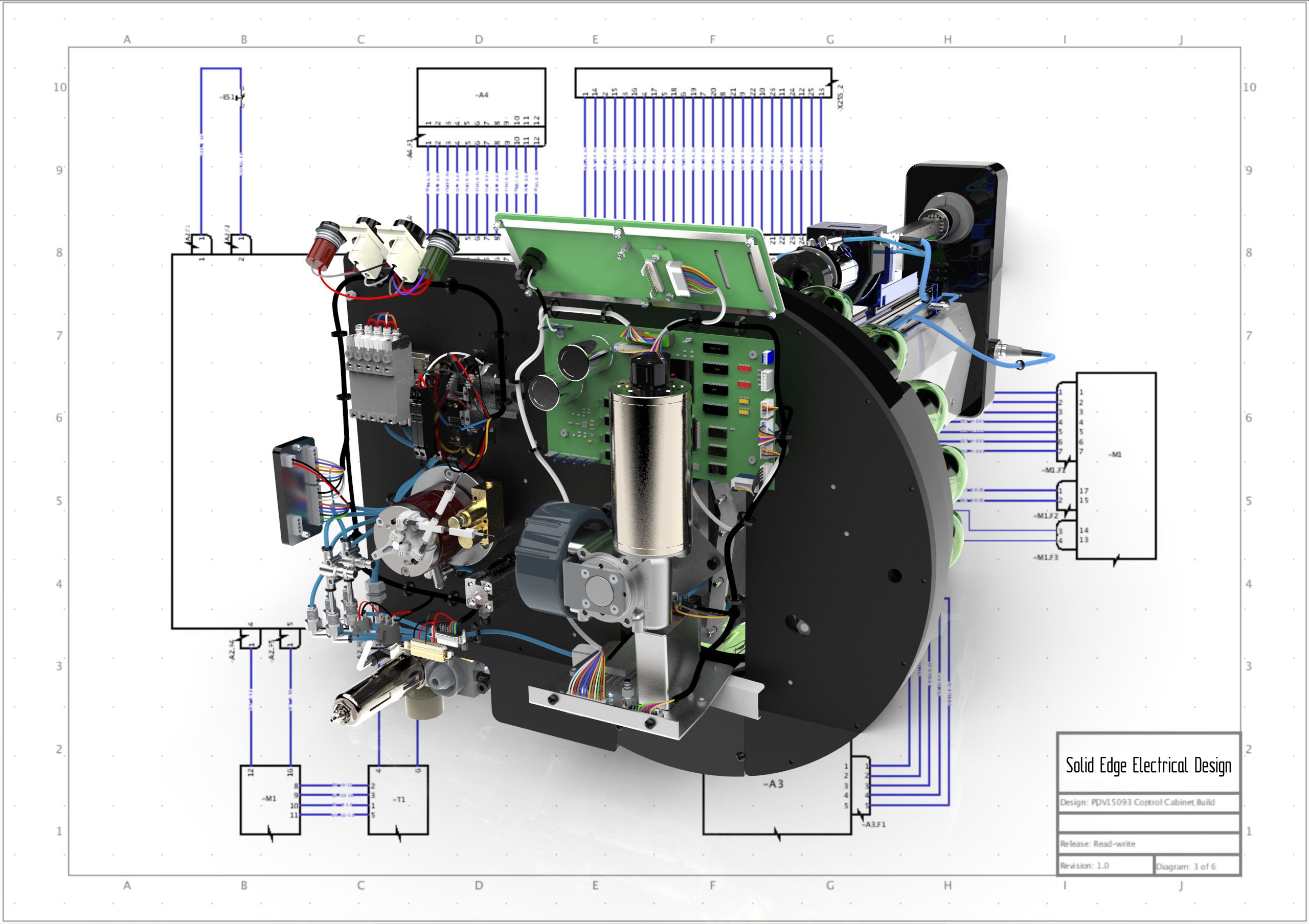

Fortunately modern design tools can deal with electromechanical complexity issues. Solid Edge makes true, integrated co-design easy. Make a change in one environment, and you see the change in the other environment… even if you are working with someone in a different office. No more waiting for design reviews; no more waiting for the weekly meeting to discuss changes that have been made, only to find out that you’ve been working on the wrong thing and have to go back to the drawing board. Sound like the nightmare scenario? Unfortunately this happens more times than people would like to admit.

The engineering.com survey, which is available for download, tells us most people meet at least once a week “to review electrical and mechanical designs.” When meetings and email are the only forms of communication between team members, something is bound to fail. As verified by the survey information, “when data flow is restricted, episodic or unreliable, the versions of systems in each discipline can be unsynchronized and different. An update that one electronic engineer makes may not be reflected in the assembly and in the worst case, the company could go into production without the most recent design.”

Uncoordinated flows are prone to human error. You’ve got the person responsible for the electrical aspect of the design providing diagrams, BOMs and drawings to the mechanical engineers, who must interpret all this information in order to figure out what wires need to be routed where. Now, the key word here is interpret. With engineers working in two different environments, it can be difficult to communicate about the most basic things, such as which wire has the problem? The electrical engineer is looking at a line on the diagram while the mechanical engineer is more than likely seeing it in a 3D CAD program. The traditional separation of electrical and mechanical engineers can undoubtedly inhibit design synchronization.

At this point, you may be thinking, yes, a coordinated, integrated design flow would be nice, but that’s a luxury reserved for large corporations, and I work on a really small team. I don’t have time to worry about all this integration stuff. I have enough to worry about already!I have a job to do and no time to learn all this new stuff.

The answer lies in intuitive tools that can easily help you achieve coordination, even if you are a one-person shop and are only coordinating the different aspects of your design.Instead of using trial-and-error, why not use a data-driven solution? Today’s modern tools use data for simulation and analysis, which are the cornerstones of a connected and integrated electromechanical design flow.

The Solid Edge Wiring and Harness Design software modules offer capabilities with significant advantages for collaboration between electrical and mechanical engineers. This software comes to the Solid Edge portfolio by way of the merger with Mentor Graphics, a giant in the electronic design automation industry. This proven electrical design software was developed to specifically meet the needs of midmarket customers, for whom considerations such as ease of implementation and low total cost of ownership are important.

The Solid Edge Wiring and Harness Design software modules offer capabilities with significant advantages for collaboration between electrical and mechanical engineers. This software comes to the Solid Edge portfolio by way of the merger with Mentor Graphics, a giant in the electronic design automation industry. This proven electrical design software was developed to specifically meet the needs of midmarket customers, for whom considerations such as ease of implementation and low total cost of ownership are important.

Solid Edge Wiring and Harness Design software brings sophisticated, high-end functionality into easy-to-use tools. So, why not join the “83% of respondents who said that their design team could save time if they had an integrated system of electrical and mechanical design?”

John Hayes, president at engineering.com stated it best when he said, “Teams that work in silos of mechanical and electrical design can run into costly delays or errors.” We at Siemens encourage you to break out of your silos. Embrace co-design practices, and see what the future holds for electromechanical design. You may find there was nothing to worry about after all.

For more information on Solid Edge Electrical Design software, please visitwww.siemens.com/plm/electricaldesign

For more information on electromechanical collaboration, please download our white paper, “Improving electromechanical design collaboration.”

Comments