Smarter Glue Systems, Faster Sales: How Robatech Leverages RuleDesigner and Designcenter Solid Edge to transform adhesive applications

How a niche-industry powerhouse leverages Designcenter Solid Edge simulation and in-house automation to deliver more efficiently for customers.

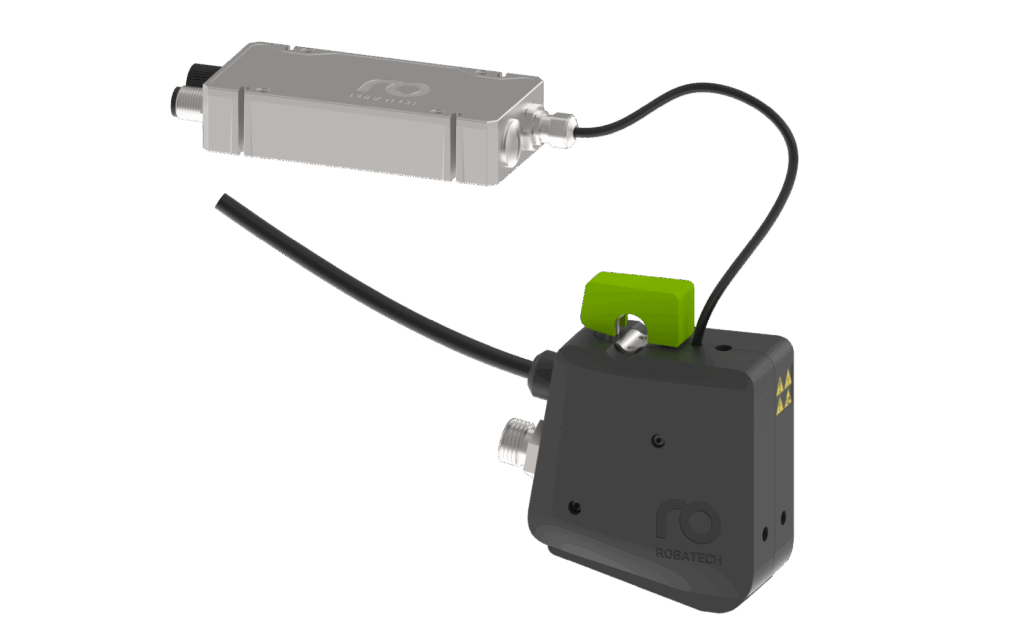

When you think of industrial innovation, glue might not be the first thing that comes to mind. Yet in industries as varied as packaging, automotive, textiles, woodworking, and bookbinding, precise adhesive application is essential. Swiss-based Robatech has made this their specialty. With more than 670 employees serving customers in over 80 countries, the company designs and manufactures advanced systems for hot melt and cold glue application — everything from adhesive melters and heated hoses to spray heads, hand applicators, and software-driven monitoring tools.

What sets Robatech apart is not only the breadth of its product portfolio but also the way it combines simulation, automation, and digital transformation to deliver reliable, energy-efficient solutions for its customers.

Tackling the Heat and Speed of Adhesive Application

Adhesive application may sound niche, but it is anything but simple. Machines in this industry often operate at extreme temperatures — up to 200°C — and apply glue at staggering speeds of 800 dots per second. Achieving uniform bead placement, maintaining insulation, and ensuring repeatable performance requires exact engineering. Even the smallest miscalculation in heat flow or nozzle alignment can mean wasted material, downtime, or customer dissatisfaction.

To address these challenges, Robatech relies on Siemens Designcenter Solid Edge. “We use Solid Edge for everything from sheet metal modeling to full assembly builds,” says Thomas Hilfiker, head of PLM & CAx at Robatech. “We design and validate our entire product range, from precision components to our largest assemblies with 1,500 parts, all using Solid Edge.”

One of the most important capabilities is computational fluid dynamics (CFD), especially the FLOEFD add-on for thermal simulations. Adhesives are non-Newtonian fluids, meaning their behavior changes with heat and flow conditions. FLOEFD allows Robatech engineers to predict how adhesives will move inside a device and how temperatures shift over time. The result is optimized product performance with minimized energy consumption — before a physical prototype is ever built.

From Engineering Bottleneck to Automated Sales

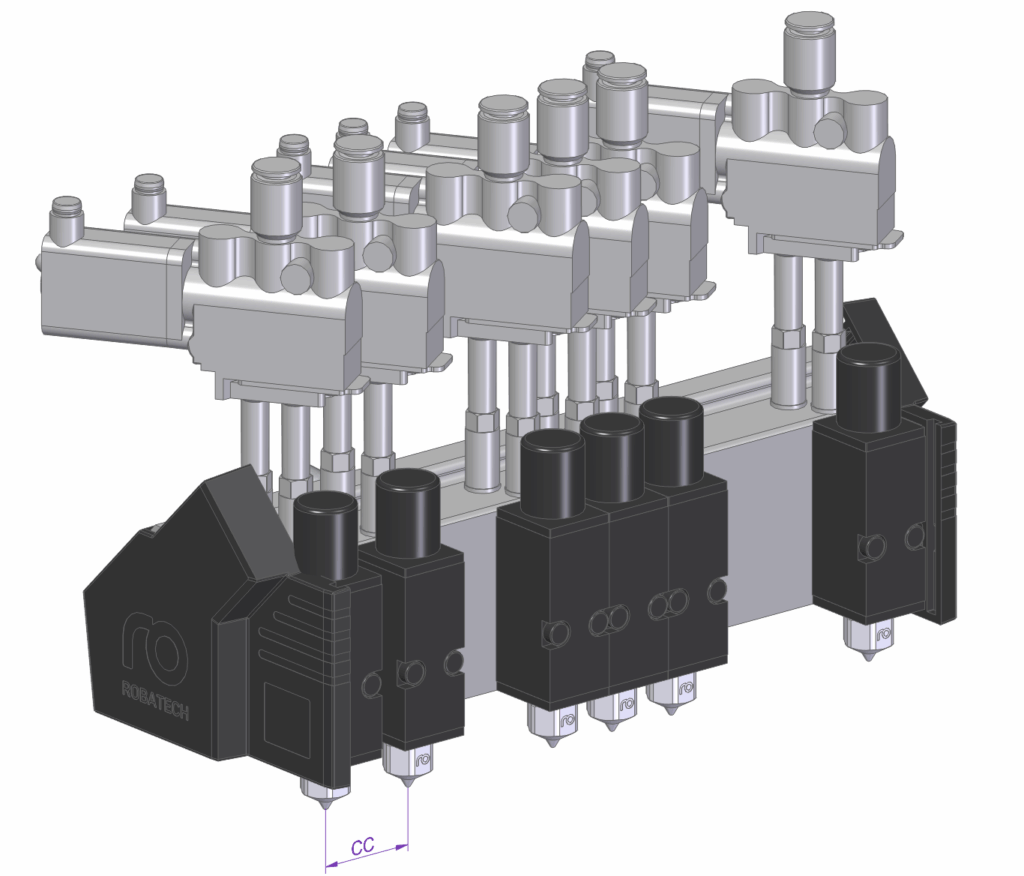

While simulation drives product innovation, automation is transforming how Robatech engages with customers. In the past, sales inquiries for customized application heads created a bottleneck: engineers in Switzerland had to manually create CAD models, assign part numbers, and prepare quote documentation. This slowed response times and consumed valuable engineering hours.

Robatech addressed this challenge by investing in a product configuration system built on RuleDesigner. Developed in collaboration with Siemens Solution Partner Var Industries, the system automates repetitive tasks that once weighed down the engineering team. The result is the Applicator Head Configurator — a web-based tool that empowers sales teams to configure products on their own.

With just a few inputs, such as valve type or number of spray components, the configurator generates a complete Designcenter Solid Edge 3D model, STEP files, dimension drawings, and pricing information — instantly. All native Designcenter Solid Edge data is stored in Robatech’s PLM system, ensuring a seamless handoff to engineering once an order is confirmed.

Hilfiker sums up the impact clearly: “The major point is that the technology team is no longer tied up in quote creation. They can focus on engineering, while sales gets what they need in minutes.”

RuleDesigner as a Cornerstone of Digital Transformation

RuleDesigner plays a crucial role in connecting engineering, sales, and business systems. With its powerful libraries, API, and integration with CAD, PLM, and ERP, RuleDesigner allows Robatech to automate not just product configuration but also documentation, pricing, and quoting workflows.

For Robatech, this means:

- Eliminating repetitive modeling tasks for engineers.

- Ensuring consistent data across departments.

- Reducing errors in quoting and design handoffs.

- Accelerating customer response times dramatically.

Although the configurator is currently for internal use, Robatech plans to eventually make it available to customers directly. This would enable end-users to generate their own models and quotes, further streamlining the path from inquiry to implementation.

Building a Digital-First Future

Robatech’s digital journey goes beyond simulation and automation. Customers today can scan a QR code on a Robatech product to instantly access manuals, spare parts lists, and relevant technical data through the company’s Customer Portal. This reflects Robatech’s goal of being “as digital as possible all across our whole system,” as Hilfiker explains.

Designcenter Solid Edge is the foundation of this digital ecosystem. It supports design, simulation, visualization, and documentation, while RuleDesigner extends those capabilities into automation and sales enablement. Together, they form the backbone of Robatech’s transformation strategy.

The results are measurable: configuring a new application head now takes just two hours instead of days, freeing engineers to focus on innovation and allowing sales to close deals faster.

A Sticky Success Story

Robatech’s journey shows how simulation and automation, powered by Siemens Designcenter Solid Edge and RuleDesigner, can drive efficiency in even the most specialized industries. By combining thermal simulation for better products with digital configurators for faster customer interactions, the company has built a system that improves productivity and creates value across the entire customer lifecycle.

As adhesives quietly hold products and industries together, Robatech demonstrates how digital transformation — with Designcenter Solid Edge and RuleDesigner at its core — is gluing the future together.