Strawberry fields reimagined: How Organifarms is automating agriculture with the help of Siemens software

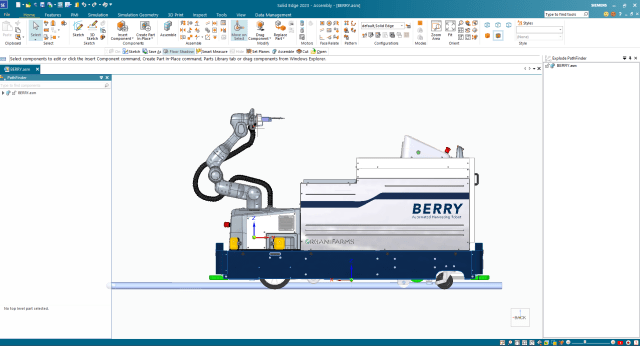

In the world of agriculture, the fusion of automation and sustainability is no longer a distant dream—it’s a reality being cultivated by innovative startups like Organifarms. This pioneering company is not just harvesting crops but also redefining how they grow, thrive, and reach consumers. At the heart of this transformation is BERRY, a state-of-the-art robot that is revolutionizing the way we approach greenhouse farming. Powered by Siemens’ software Solid Edge, Organifarms is taking agricultural automation to new heights, proving that the future of farming is not only efficient but also autonomous.

A vision born from a hackathon

Organifarms was born out of a shared passion for tackling some of the most pressing challenges in agriculture—climate change and labor shortages. Hannah Brown, one of the co-founders, found herself at a crossroads while working on her master’s thesis. The academic route felt too detached from the real-world impact she craved. A climate change hackathon in 2019 presented the perfect opportunity to channel her desire for hands-on innovation. It was here that the seeds of Organifarms were planted, and the mission to address the future’s agricultural challenges took root.

“During the hackathon, one of my co-founders pitched the idea, which was on sustainable agriculture and tackling the problems of the future, one of which is the labor shortage,” Brown recalls. “We started working on solutions and quickly realized that automation was key.”

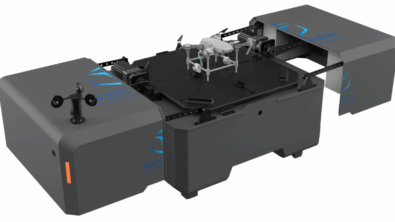

Meet BERRY: The Autonomous Harvesting Robot

BERRY is no ordinary robot—it’s a marvel of engineering designed to work tirelessly, 24/7, ensuring that greenhouse farming becomes more efficient, economical, and sustainable. The robot’s primary function is to harvest strawberries, but it does much more than just pick fruit. Equipped with advanced sensors, BERRY can assess the quality and ripeness of each strawberry, collect data on plant health, and determine how many ripe fruits remain.

The robot’s precision is unmatched. Using its robotic arm, BERRY delicately harvests each strawberry at the stem, ensuring that the fruit remains untouched and pristine. The harvested strawberries are then placed into storage containers, ready for transfer to cold storage once the harvest is complete. This level of automation not only addresses labor shortages but also reduces production costs, setting a new standard for sustainable farming.

Beyond Harvesting: A Data-Driven Approach to Agriculture

What sets Organifarms apart is its commitment to leveraging data to improve agricultural outcomes. BERRY is more than just a harvesting tool; it’s a data-gathering powerhouse. As it moves through the greenhouse, the robot collects valuable information on plant health, stress levels, and potential diseases. This data is then processed by Organifarms’ software, providing growers with predictive insights and forecasts that can significantly enhance crop management.

“We can analyze the data to help the grower with predictions and forecasting. We can also do disease detection. It’s a kind of stress detection on the plants, which helps users intervene quickly and be able to save more plants, should an issue arise,” says Brown.

Moreover, BERRY is equipped to perform UV-C treatments that can increase branching in some plant species. These treatments, performed at night after harvesting, help in disease prevention and reduce the need for chemical interventions like fungicides and pesticides.

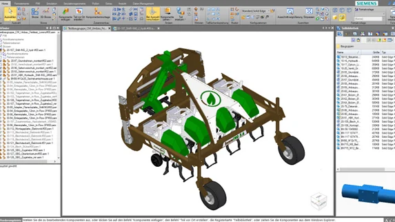

The Role of Siemens’ Solid Edge in BERRY’s Development

The success of BERRY is not just a testament to Organifarms’ ingenuity but also to the powerful tools provided by Siemens. Solid Edge has been instrumental in the development of BERRY’s critical components. From designing custom gripper housings to optimizing the robot’s storage system, Solid Edge has enabled Organifarms to build a robot that is both functional and adaptable.

“Using Solid Edge, we’ve been able to design and iterate on essential parts that we couldn’t buy off the shelf. Without these components, BERRY wouldn’t work,” Brown explains.

The software’s sheet metal capabilities have also played a crucial role in manufacturing the robot’s integrated storage for strawberries, ensuring that BERRY’s design is both efficient and practical.

A Digital Future for Agriculture

Looking ahead, Organifarms envisions even greater integration of digital tools in their operations. With the potential to develop a more sophisticated digital twin system, the company aims to enhance its simulations of BERRY’s movements and operations, leading to better training, optimization, and overall performance. Collaboration with Siemens could further expand their digital capabilities, potentially incorporating advanced solutions like Simcenter to offer a fully integrated digital journey for their customers.

Organifarms is not just a startup—it’s a beacon of innovation in the agricultural industry. By combining cutting-edge robotics with powerful software tools like Siemens’ Solid Edge, the company is paving the way for a future where farming is more sustainable, efficient, and data-driven. As BERRY continues to evolve and expand its capabilities, Organifarms is set to make a lasting impact on the world of agriculture, one autonomous harvest at a time.