6 Common Mistakes in Additive Manufacturing

When implementing a new platform, it’s easy to make a costly error without realizing until it’s too late. Mistakes always cost money and can ruin your business if they’re big enough. It’s simpler, cheaper and far less painful to learn from other people’s bad business decisions.

Here are 6 common pitfalls when launching an additive manufacturing system and how you can avoid them.

1. Choosing the wrong AM system

This is the big one and it could bring an end to your own personal industrial revolution in additive production before it begins. Selecting an additive manufacturing system sounds simple, but this is complex, fast-moving technology. Even if you get the right system today, there’s a chance it could be the wrong one next month.

The only way to avoid the problem is to hire the right people before you commit to an AM set-up. Define your goals, account for other 3D printing tasks in the planning stages and make sure you have a solid system that serves all your needs.

Consider a modular design for your production line too, as both your company and the technology will evolve. A flexible floor-plan where individual units can be easily replaced is a basic requirement in the emerging science of additive manufacturing.

Until you’re truly familiar with additive printing and ready to invest serious money, it might be safer to order 3D printing online from an outside supplier using the 3D cloud. Metal 3D printing, in particular, is a challenge, and a smart move could be to entrust it to experienced professionals as you build your expertise.

2. Choosing the wrong software

The wrong 3D printing software package isn’t as difficult to fix as the wrong hardware, but it’s a mistake that could cost you money forever and you will never know. The inefficiencies and problems you come to accept, especially if you’re using several different packages, might never occur with the right manufacturing optimization software.

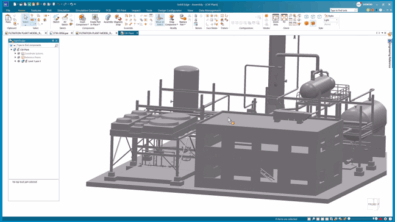

More and more companies are opting for end-to-end 3D printing software packages that deal with everything from the design stage through to the post-print validation. Packages like Solid Edge Additive Manufacturing software enable an end-to-end solution from design, through validation, to machine code generation. Miscommunication and other problems are eliminated by design.

Past performance is the best indicator for the future, so build a shortlist and talk to potential suppliers. Ask how this specific machine and software package has previously solved the problems you face.