Boost CNC efficiency with NX CAM: The power of digital twin and validation together

In today’s fast-paced manufacturing landscape, precision and efficiency are non-negotiable. That’s where NX CAM and the power of the digital twin come into play. In a recent webinar, we discussed how NX CAM accelerates processes for machine shops, and one critical advantage stood out: the ability to validate processes early using a digital twin. You can watch the on-demand version of the webinar here.

The Power of the Digital Twin

One significant advantage of the digital twin is that it offers a complete virtual representation of your machining setup and the part you’re working on. By validating processes digitally before hitting the shop floor, you can avoid costly issues that could arise in production—such as tool collisions, setup problems, or inspection errors. By identifying potential issues upfront, you save not only time but also money, eliminating unnecessary downtime for your machines and ensuring your production remains on schedule.

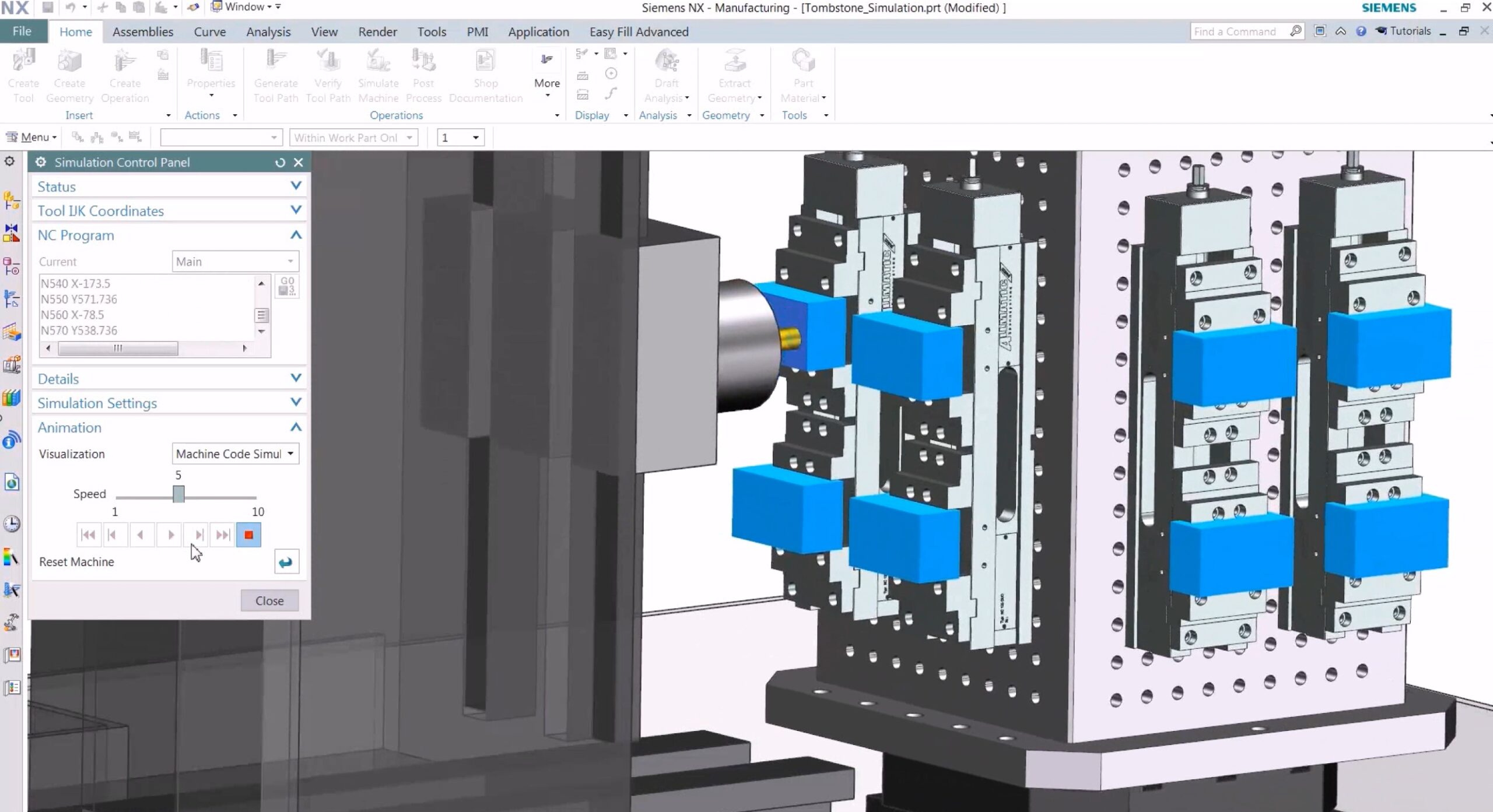

G-Code-Driven Simulation: A Game-Changer

G-code-driven simulation is a key feature in NX CAM that allows for seamless optimization of part manufacturing. Unlike many other machine shops that rely on standalone add-on simulation software, NX CAM offers a fully integrated environment where you can simulate machine tools within the same system where NC programming occurs.

Why does this matter? You can validate machining operations in real-time, making it easier to foresee exactly what the G-code will do, such as tool changes and movement. This leads to an accurate, error-free process simulation using the digital twin. The result? You avoid bottlenecks in production, streamline your workflow, and increase operational flexibility—all while minimizing the risk of costly errors.

Integrated Process from Design to Production

A key takeaway from the webinar is how critical it is to have an efficient process from design all the way through NC programming and quality inspection. Machine shops need to integrate CAD and CAM data seamlessly, and NX CAM makes that possible. With synchronous modeling, machine shops can quickly edit any 3D solid, regardless of how it was created. This allows shops to efficiently handle design data coming in from multiple sources, helping them respond quickly to customer needs.

For example, suppose you need to move a feature like a rib. In that case, the system will automatically account for associated elements like fillets and surfaces, making the editing process intuitive and fast. NX’s powerful design capabilities help machine shops tackle everything from part modeling to drafting, giving them an edge in production efficiency.

The Closed-Loop Inspection Process

Another standout feature discussed in the webinar is how NX integrates inspection into the manufacturing process. CMM (Coordinate Measuring Machine) programming enables you to create complete inspection programs with just the click of a button by leveraging PMI (Product Manufacturing Information) data attached to the part model. This seamless integration means machine shops can generate inspection programs and machine-specific code for their inspection equipment with minimal effort.

Moreover, the closed-loop inspection system in NX allows for shop floor measurements to be read back into the digital twin. By overlaying the as-built measurements on the digital model, machine shops can compare and analyze deviations between the design and the final product. This feedback loop provides crucial insights into process optimization, helping shops maintain high-quality standards while reducing rework and waste.

The Path to Smarter Manufacturing

NX CAM’s powerful simulation tools, integrated design environment, and closed-loop inspection capabilities make it a game-changer for machine shops looking to improve their efficiency and accuracy. By leveraging the digital twin, G-code-driven simulation, and synchronous modeling, manufacturers can validate their processes early, reduce downtime, and achieve error-free production. The ability to seamlessly move from design to NC programming to inspection—while ensuring everything stays integrated and efficient—is critical to staying competitive in today’s manufacturing world.