Experiment vs. Simulation, Part 1: Them and Us.

Before you sell it, or commission it, you want to be sure that it works. Monies have been spent on getting things this far, some of it on you via your overhead and your expansive salary (yeh, ok, I hear you). Expectation is that your organisation will make more money back. Last thing you want is to have your product fail, have to be tweaked, fixed, respun, redesigned or canned. What you’d like is for the first prototype to just work, meet its design constraints, pass all the QA checks and be shipped. Once out there in the market you certainly don’t want to start seeing field returns. Today we see simulation and experimental measurement used in conjunction to keep the product design wheels of the technology industry moving. It wasn’t always the case.

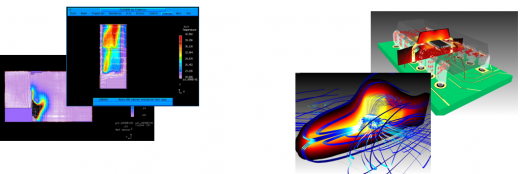

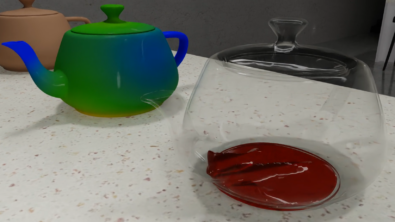

Flomerics started back in 1988 as a CFD company, split out from CHAM, that quickly established itself as leader in vertical application CFD products. FloTHERM was actually the first CFD tool with a fully integrated GUI containing all pre- and post-processing capabilities in a single tool. Targeted at the simulation of electronics cooling systems it experienced rapid success and still enjoys a market leading position in the industry. I personally started as an AE (application engineer) in 1996, working with sales to demonstrate the value of the technology to prospects. All very missionary as at the time we were pitching ourselves as an alternative to ‘build and test’ prototyping approaches. It was a clear argument to propose. Using simulation one could perform more ‘what if’ studies to more quickly evolve your design concept into one that would be thermally viable. This compared with using large cardboard boxes to mimic your chassis or enclosure, cutting holes in them, using a powered PCB with the same amount of power as what will be in the final product, playing around with vent configuration, changing fans, measuring dP etc. That was common, I kid you not.

The CFD had to be robust and well packaged to be easily used by the engineers that we were targeting. ”You don’t have to be a CFD scientist as well to continue being a thermal design engineer”, you get the picture.

You can tend to suffer from hubris being the newest tool in the toolbox. We had to pitch ourselves as a better alternative to experimental methods but at the same time not go so far as to say simulation with FloTHERM would be a full replacement. With a bit of design method option shoulder barging we settled down into the position that FloTHERM would help you minimize the risk of your first physical prototype failing. Simulation is useful but I wouldn’t go straight to market without physically verifying my product first.

FloTHERM’s come a long way since the late 80s, as have experimental methods. Flomerics acquired MiCreD, provider of thermal measurement and characterisation products, in 2005. Today, with both forming part of the Mechanical Analysis Division of Mentor Graphics, we are in a unique position to provide more complete synergistic solutions to aid in the thermal design of today’s electronic products (and products that contain electronics, which are many!).

I’ve always had a problem with such glib marketing phrases as ‘complete synergistic solutions’ so my apologies for letting that one dribble out. Better to focus on some real technical demonstrations. From structure functions to JESD51-14, from integrating spheres to optically adjusted DCTMs of LEDs, over the next few parts of this blog series I’ll cover the various ways in which simulation and experiments can become better bedfellows, parenting the creation of world leading products [the key thing about similes is knowing when to stop them].

18th January 2013, Ross-on-Wye.