Underfloor Thermal Insulation; Why? Part I

I’m building an extension to my house at the moment. Actually, let me qualify that; I’m doing some of the easier work, a builder is doing the difficult bits like the walls, roof, windows etc. Part of the building regs that detail the groundworks (everything up to the damp proof membrane, including the floor structure) demand that a thermal insulation layer is included in the floor ‘stack-up’. Not cheap compared to concrete which is by-the-by what with regs being “regulations”, it’s non-negotiable. So, what does this mean for the resulting thermal behaviour of the as yet un-built extension? Let’s simulate it to find out…

The underfloor section of the groundworks is built up of a number of layers, from the excavated earth surface itself up to the tiles/flooring that will be placed on the top of the stack. One of my sons and I had great fun recently in putting these layers in (well I had fun). From 16 tonnes of scalpings (loose hardcore with stones no bigger than ~50mm in lots of sand) which we shovelled manually then packed down with a whacker plate, to a 20 mm ‘blinding’ of sand on top of that, to the damp proof membrane (dpm) on to which the thermal insulation boards were placed then subsequently a 100mm concrete screed was poured on top of that. Here’s the first 4 layers progressing:

(note exhausted son on dpm)

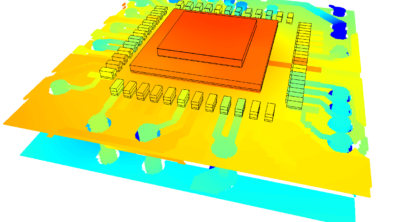

For the simulation (bread and butter application of FloVENT) I’ve modelled an end section of the extension from the earth upwards to the ceiling of the ground floor (that’s the first floor for most of the rest of the world). I decided to model the floor stack-up without the thermal insulation layer to begin with, assumed that 200mm of concrete screed was used instead. Here’s a picture with one of the side walls not shown and the ceiling shown as wireframe for clarity:

FloVENT is great for creating realistic representations with the use of texture mapping, the window and picture were simply digital photographs taken in the existing house! To simulate the resultant internal room temperatures I put a hot radiator in and appropriate thermal conductivity values of all the materials used.

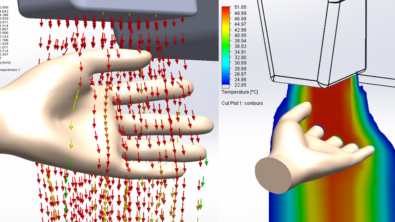

The results when compared to when a thermal insulation layer was included were interesting…. I’ll leave the details until the next blog entry on this subject. For now I’ll leave you with a nice picture of the internal air flow distribution and resulting surface temperatures inside the room.

28th September, Hampton Court