“All models are wrong, but some are useful” Part I

The original business case that David Tatchell and Harvey Rosten put forward for the formation of (what was to become) Flomerics had the following quote on its front page:

“All models are wrong, but some are useful“

G. E. Box

This sentiment has underpinned the approach my colleagues and I have always taken in the packaging up of computational fluid dynamics technology for the thermal simulation of electronic systems. It still does so as we now continue to work as the ‘Mechanical Analysis’ division within Mentor Graphics. The quote is our pragmatic dogma. This and the following few blog entries will explore the issues associated with the usefulness, accuracy and cost of CFD based electronics cooling simulations.

Back in the day (and sometimes even now) the issue of the predictive accuracy of FloTHERM was front and center of each sale. “How accurate is FoTHERM?” was answered in a number of ways:

“Accurate enough to be useful”

“It depends on the accuracy of your input data”

“It depends on the accuracy of your experimental measurements”

And finally, when push came to shove:

“Usually ~10% on dT predictions”

With the following response: “O, really, err, ok then”. Such a response I put down to expectations that are more often than not laid down and set in academia. A wonderful environment, free and unfettered from the restrictions of time (=$$) and singularly minded in the pursuit of accuracy at all costs.

Should we ever be happy with 10%? Yes, and in addition we should be somewhat surprised with <5% and unbelieving of <1%.

Why? Why be accepting of something that could be smaller, could allow FloTHERM users to have an even greater confidence of the thermal compliance of their yet to be made electronics? There’s a long nasty line up of suspects, the ring leader of which is power dissipation.

Power, Q (Watts -> J/s ->Nm/s (speed, hmm, more on that some other time…))

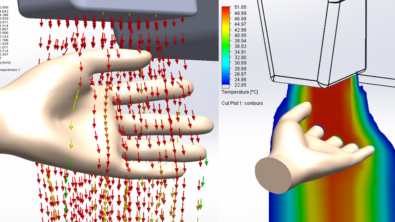

Power, it’s why you need tools like FloTHERM, that and the fact that solid materials tend to grumble by getting hot when you first dissipate heat in, then force heat to pass through, them.

Electronics cooling is getting the cold in to quench where the power is being dissipated as quickly/easily as possible. Conversely it is trying to get the heat out as quickly/easily as possible to stop the temperature building up at the power source. Either way, power’s a main culprit.

So what form do power dissipation errors take?…

Usually, in an electronics cooling simulation, you’ll be assuming a steady state of your system, meaning in this case that the power dissipation in the die is unchanging in time and therefore an time averaged value should be sought and used. Alternatively if you are performing a transient simulation you might be assuming that the time averaged value changes from one value to another. For many packages and operating behaviours such assumptions themselves will contribute to the overall simulation error.

There was a study once (whose reference alludes me) of taking two ‘identical’ packages from a production line, powering them up and measuring their actual consumption. The consumption that should have been identical varied by ~10% between the two.

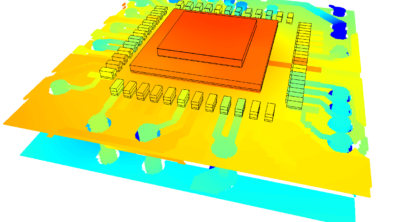

If you are using a detailed model of a package in your simulation, where the important internal 3D geometric structures are explicitly represented (e.g. lead frame, tie bars, heat slug etc.) likely you’ll be assuming that the die is a single piece of Si with the power dissipation uniformly spread over it. This assumption can also carry an error. (Note that in the V8.1 of FloTHERM you can use the Die SmartPart to specify a non-uniform collection of discrete areas with differing power dissipation over the die, this goes a long way to shed the inaccurate assumption of overall die power dissipation uniformity).

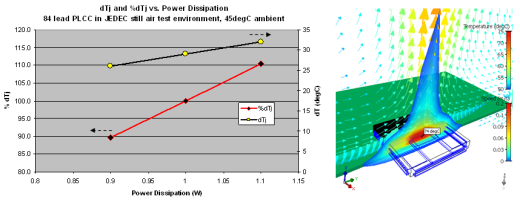

So what is the relationship between power inaccuracy and resulting thermal predictive accuracy? Hey, good question. I did a little study in FloTHERM, took a detailed model of an 84 lead PLCC, stuck it on a 2S2P test board in the standard JEDEC still air test environment, set the ambient temperature to 45degC and solved at 1W, 0.9W and 1.1W (~10 minutes start to finish, man, I love FloTHERM!). Looking at the resulting Tj values I found that if power dissipation is known to within +/- 10% then the resulting dTj (Tj rise above ambient) is also +/-10% accurate. (Hey, thermal experts, under what situations would it not be a proportional relationship when Q+/-10%?).

The point about this power inaccuracy issue is that there will be inaccuracies that you will have to carry and suffer not because you are a poor modeler, but because of assumptions you have to make due to the utter lack of good quality thermal data. Getting even the average power dissipation for the package as a whole is difficult enough, let alone knowing how to account for manufacturing variations in the package construction! Experience has shown that in a design world of unknowns and unknowables a +/- 10% accuracy of an electronics thermal simulation is to be expected, not feared. If you believe your design requires predictions of even tighter margins then I’d be more worried about your design itself rather than its simulation.

There are suspects in the line up of modeling errors that you as a modeler will have control over. Whereas power dissipation inaccuracy is something you have to suffer, there are others that you could be responsible for….. more on that in Part II

Robin Bornoff

Hampton Court

May 12 2009