Oil and gas: novel computational chemistry methods for a brighter future

Can computational chemistry methods help build a more sustainable future? Read how Petronas innovates using computational chemistry to transform the oil and gas industry.

What is computational chemistry?

Computational chemistry is a branch of chemistry that uses computer simulation to help solve chemical problems. Computational chemistry methods are based on theoretical chemistry incorporated into computer programs to calculate the structures and properties of molecules, groups of molecules, and solids.

Today, it is best known for its capacity to innovate the pharmaceutical sector. Just look at how it’s currently helping researchers design drugs and vaccines to combat the SARS-CoV-2 virus. And it’s not just about the root virus of the COVID-19 disease. Faster than ever, we can understand the mechanisms of thousands of viruses. And consequently, we develop targeted drugs to fight them.

Why is it easier today than yesterday? Firstly, engineers and researchers have put a massive effort into developing novel computational chemistry methodologies. And secondly, because of the tremendous increase in the processing power of modern computers.

Nowadays, many industries rely on computational chemistry, from personal care to petrochemical or electronics companies. Computational chemistry methods help the R&D teams develop and optimize new formulations and production processes.

Computational chemistry methods for the oil and gas industry

Simcenter Culgi is a complete software suite for computational chemistry. It plays a significant part in helping R&D engineers develop new processes, most notably in the fossil fuel sector.

Why does it matter?

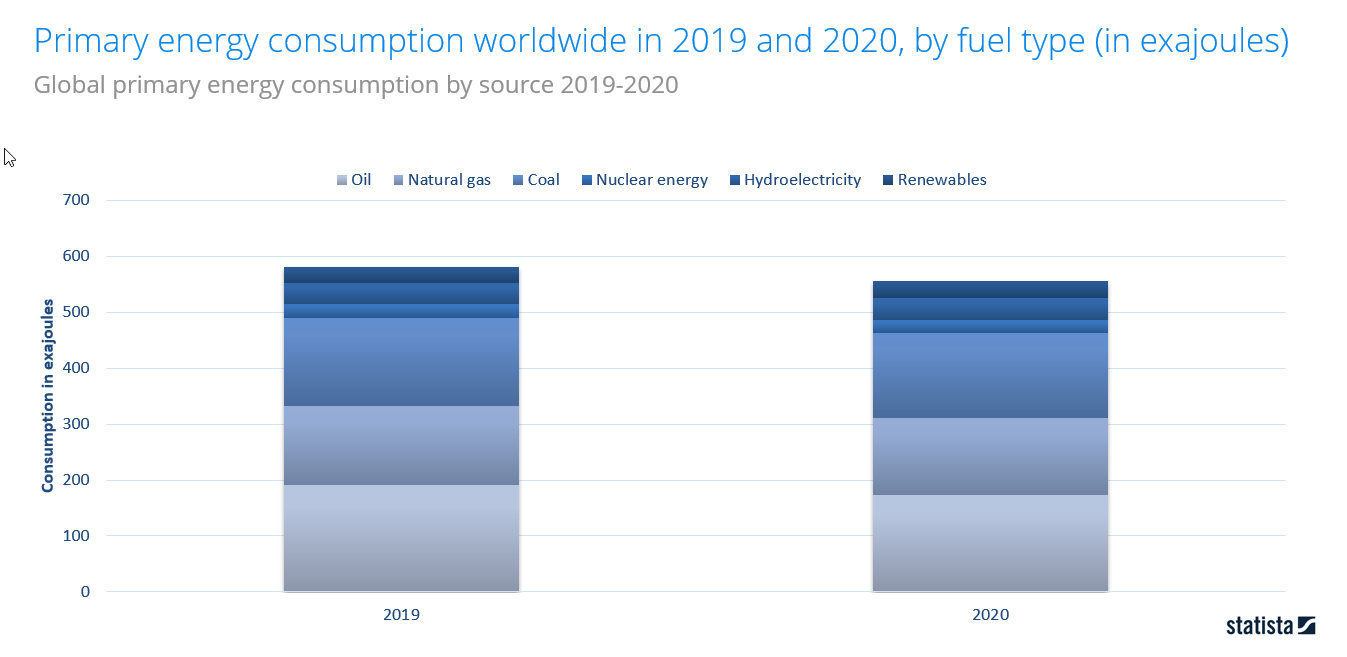

Fossil fuels now account for three-quarters of the world’s primary energy consumption in transport, industry, and housing. And, they are also essential to the production of electricity.

(Click to enlarge – Source: Statista)

If it wasn’t on the top of your mind already, the COP26 reminded each of us of the importance of greenhouse gas emission reduction. The annual IPPC reports are increasingly alarming. But there’s still hope: the reports show that we can limit our already considerable impact on the environment – if we do it NOW.

Efforts to reduce the carbon footprint

Step by step, numerous countries attempt to reduce their carbon footprint. They invest in renewable energy sources, wind turbines, solar panels, or hydropower, thus decreasing their use of fossil fuels for energy production.

The fossil fuel providers, the oil and gas companies, are also trying to limit their carbon footprint by increasing the efficiency of their oil production and by investing in renewable energies. They want to ensure the perennity of their business as energy providers while taking their share of the environmental responsibility that our humankind holds.

But oil is not only fuel; it’s also a raw material

Indeed, fossil energy doesn’t solely power cars, propel planes or drive production plants. In fact, crude oil is omnipresent in our lives, much more than we realize. Oil is the raw material used to produce plastics, gums, and fertilizers. It is also in our detergents, our shoes, and even our contact lenses. When unearthing crude oil, we also found an abundant raw material source to produce an endless amount of products.

Let’s face it: our economy is now dependent on these oil-based products. Although the industry is exploring alternatives, it’ll take a few more decades before we produce oil-free goods exclusively.

What’s the option, then?

Can the industry develop more sustainable oil-based products? Would that help the planet?

Some researchers believe so and work relentlessly to develop the next generation of plastics and oil-based products.

A more sustainable plastic?

Could an efficient use of crude oil help reduce a product’s carbon footprint?

Some believe that using oil to produce consumer goods rather than energy could help minimize the environmental footprint of said products. And results in a much more efficient production process.

Today, only 8 to 12% of an oil barrel serves to produce consumer goods. But in reality, up to 50% could be refined into essential consumer goods. Some companies aim to increase this percentage up to 80%, consequently reducing an average barrel’s carbon footprint.

We are targeting 70% to 80% of each barrel of crude oil being converted to chemicals in a competitive manner.

Ammar A. Al Nahwi, R&DC manager, Aramco

This efficient use of crude oil helps reduce carbon dioxide emissions and improves economic stability. Beyond that, R&D teams work to develop innovative, more sustainable materials based on crude oil shortly.

How Petronas addresses future challenges with computational chemistry

Petronas doesn’t only invest in producing oil-based chemicals for consumer goods. The company goes a step further using innovative computational chemistry methods.

PETRONAS Chemicals Group Berhad (PCG) was established as part of the PETRONAS Group. The company manufactures, markets, and sells various chemical products, including olefins, polymers, fertilizers, methanol, and other basic chemicals and derivative products.

But developing chemical substances requires significant R&D efforts and consumes a lot of raw materials. This is why the PETRONAS Group chooses to investigate digital solutions through their research center, PETRONAS Research (PRSB), to innovate products better, faster, and in a more environmentally-friendly way.

The power of computational chemistry

Using Simcenter Culgi, the PRSB teams developed a digital laboratory to test new molecules en masse without any experimental testing. They could create a numerical model representing their various types of crude oil, limiting the empirical research efforts.

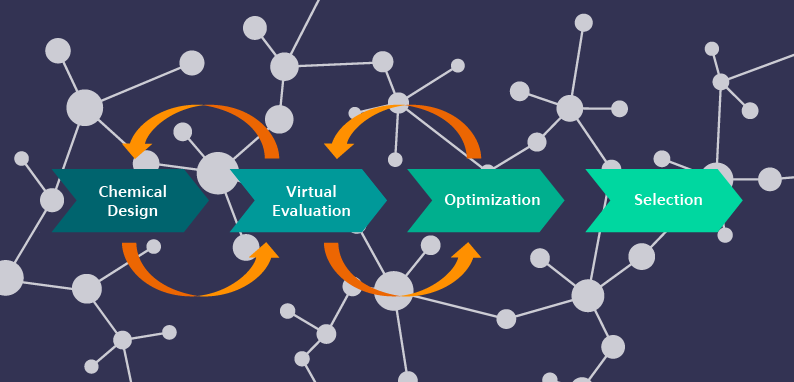

Using the power of computational chemistry, they set up a numerical protocol that allowed creating new molecules, testing and modifying them without ever going to the lab.

How did the Petronas team set up a virtual chemistry lab?

Together with Simcenter Culgi’s experts, they developed a digital crude oil model. This model relies on available experimental data. The scientists compared its numerical properties, such as its density, to the experimental measurements. They performed a series of virtual experiments on 14 different well-known surfactant mixtures typically used in Chemical Enhanced Oil Recovery based on the validated model. Their aim was to check whether the model properly predicted the best surfactant on the field.

Experimenting – faster than ever

Usually, those experiments can take up to 2 months. But the simulations require only a few days. More, they can be stopped at any moment, for example, if the results don’t look promising in the first few hours. Faster is better, but are the simulations correct? Well, the virtual laboratory results show an accuracy of 85 %, which definitively validates the usefulness of the method.

Pushing the boundaries of virtual chemistry

The PRSB teams kept using the method to automatically design and test novel molecules, changing their compositions, getting insights into what works and what doesn’t – all of that without engaging any cost for laboratory tests!

The outcome? Astonishing!

As a result, the PRSB teams have reduced their development costs by 85%, minimized human intervention, and accelerated their innovation process by 96%.

The PRSB success story

Thanks to computational chemistry, the PRSB teams optimize the consumption of available crude oil used for manufacturing essential goods. Firstly, they achieve this result by limiting the number of experimental tests required to create a new molecule. Indeed, in a physical laboratory, synthesizing a single molecule requires a large amount of human intervention, including mixing toxic products. In the virtual laboratory, one mouseclick replaces 1 month of tests.

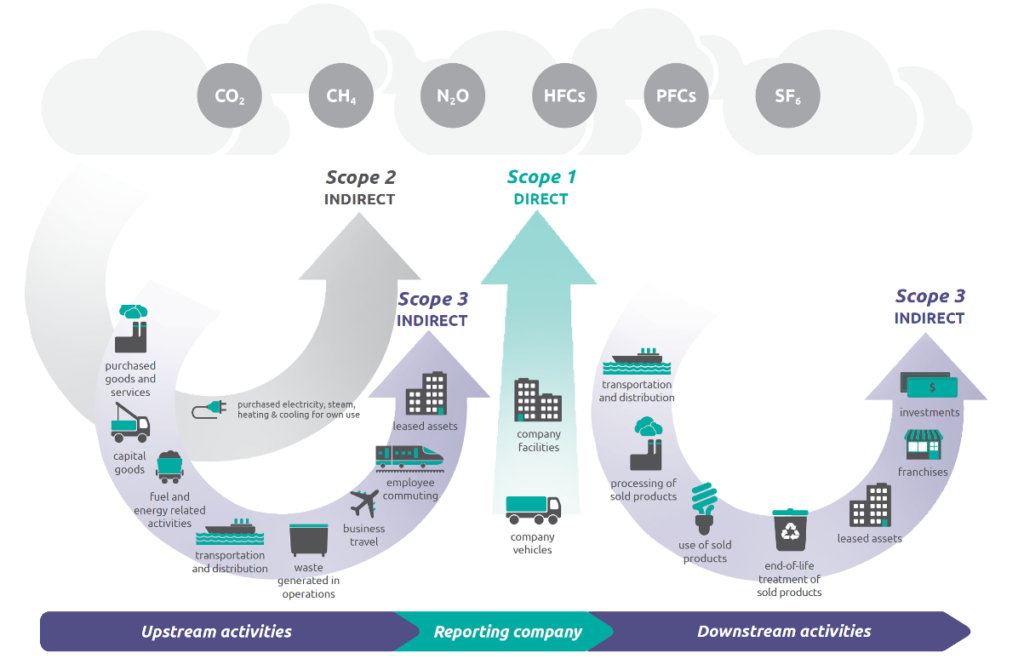

Secondly, since the PRSB teams precisely control the molecules, they can ensure that they do not contain nefarious components that produce Scope 3 emissions. Scope 3 emissions are all that we, consumers, generate by using manufactured products, from driving our car to drinking water from a plastic bottle. Designing environmentally-friendly compounds close the circle of greenhouse gas emissions origins.

With the PRSB virtual lab, the PETRONAS Group sets new standards for its environmental, social and governance (ESG) ambitions. It initiates a transition to more profitability and economic stability while using pioneering technologies to reduce its carbon footprint.

Are you ready to adopt computational chemistry methods?

In conclusion, while computational chemistry is still marginal in many industries, it brings tremendous benefits to the companies that adopt it. The development of virtual laboratories shows how effective the methodology is. It helps petroleum companies transition from delivering an energy source to transforming and using this energy more sustainably. Companies can actively reduce their carbon footprint while improving people’s lives. To help you set up your own virtual laboratory, Simcenter Culgi offers a versatile platform to simulate the most complex systems faster. It allows a better understanding of how a material’s composition influences its final properties, effectively resulting in better products with lower carbon impact.

Learn more about innovative computational chemistry on the Simcenter Culgi website.

Interested to learn more about the PRSB project? Don’t miss the live webinar on March 9, 2022. Stay tuned for more information.