Making the Transition to an Integrated CAD/CAE Environment

Today, thanks to the Internet, even the phrase “in the blink of an eye” has nearly become obsolete, as we are able to type something into a search engine and get results in three centiseconds. That’s three times faster than you can blink!

This speed has driven the demand for immediacy: We live in a culture of now. “People must be engaged in a culture of continuous improvement,” states Ed Roubal, design engineering and tooling director for Graham Packaging Company. So where does this leave product development engineers?

Both CIMData and Scientific Computing World have noted how pivotal to product development CAD/CAE integration is. But due to a longstanding history both within organizations and the PLM industry as a whole, a culture of separateness has endured.

Three factors contribute to the cultural issue of CAD and CAE integration: People, Process and Technology. We will delve into these further in future posts to come, but for now let’s look at where the problem originates and why integration matters.

Divergence between CAD and CAE stems from the way the technologies evolved. Design and analysis were completely separate processes performed by different departments. Only recently has the market has begun to shift toward incorporating analysis into the early design stages. Many companies, however, have yet to make the transition due to the cultural issues we will explore.

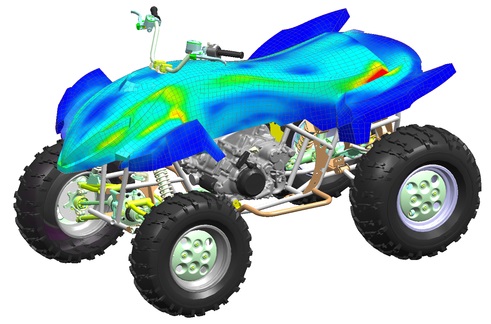

We’ve talked before about how simulation driven design solves problems early on in the product lifecycle. Paul Schrier refers to this process as CAE-centric design, but the meaning is the same: Engineers validate and change designs based on simulations conducted in early concepting. This speeds up the design process and improves the overall design because it guarantees your design will work as you intend.

Siemens PLM Software offers a comprehensive system that is fully integrated between NX CAD and NX CAE. This CAD/CAE integration enables engineers to collaborate and share information. This supports innovation, because there are more ideas readily available to implement and try. Someone may just come up with a solution you didn’t see.

Furthermore, NX Synchronous Technology makes implementing new tweaks to designs fast and simple, which ultimately improves workflow. It allows you to edit native or imported CAD geometry in the model without understanding how the geometry was created originally (the model history).

NX also maintains associativity between the CAD model and the CAE model. When a user edits CAD geometry, there’s no need for you to manually recreate the analysis model because the mesh and boundary conditions are associated to the base design and the definitions can be updated automatically to reflect the new, updated design. This all contributes to a faster, more efficient environment so you can focus on what’s important: designing a better product.

Look for the next article where I will discuss the cultural issue of CAD and CAE integration in relation to people.

-Amy