Top 4 reasons why fleet maintenance will make OEMs successful

Should you, as a manufacturer of machines such as bulldozers, excavators, cranes, tractors, harvesters, and alike increase your focus on fleet maintenance and aftermarket services? Should that become a key pillar of your global business? That’s the million-dollar question. And if yes, how can you provide fleet maintenance most effectively for today’s innovative machines? (Spoiler alert: you need a connected service lifecycle management solution)

OEM or third party for fleet maintenance and aftermarket services?

Ask your customers and you’ll hear different opinions. There are pros and cons to either going with the original equipment manufacturer (OEM) or involving a third party for fleet maintenance.1 Even if the OEM seems like the most logical choice altogether, for many it turns out not to be the most popular one. The prime concerns? Nontransparent pricing, high operating and repair costs, lack of flexibility, and unresponsive sales reps, dealers, and technicians, according to a survey that was carried out by McKinsey.2

Besides, what do you, as an OEM, know about the exact conditions in which their machines are being used, and so what fleet maintenance schedules should be? If it breaks, your standard answer is ‘yes, but it was not designed to be used like that’ anyway. Not?

Digitalization as momentum for a changing view on fleet maintenance

That’s the older generation speaking. Times are changing. And so are products, business models, and customer preferences. In just a decade, we’ve entered a totally new era across industries. Digitalization is skyrocketing. Even traditionally slow technology adopters like farmers, who like to monitor their crops by walking their fields, and contractors, who used to track progress at construction sites with manual checklists, are now hooked on their apps, drones, and phones.2

Heavy equipment OEMs and their customers are now connected and can be continuously in touch. This changed their relationship and what they expect from one another. Farmers and contractors now trust OEMs to guide them through digitalization, including digitalization of their fleet maintenance and aftermarket services, while OEMs increasingly see themselves as solution providers rather than as product sellers. Thinking that way, fleet maintenance and aftermarket services become a value creation opportunity, rather than a cost.3,4

In one of its many articles on the topic, McKinsey takes it even a step further, saying there’s a gold mine waiting for OEMs in aftermarket services!5

So, have you started digging?

In this blog, we give you 4 reasons why you must urgently upscale your fleet maintenance activities and aftermarket services.

Reason 1: secure your margins in economic downtimes with aftermarket services

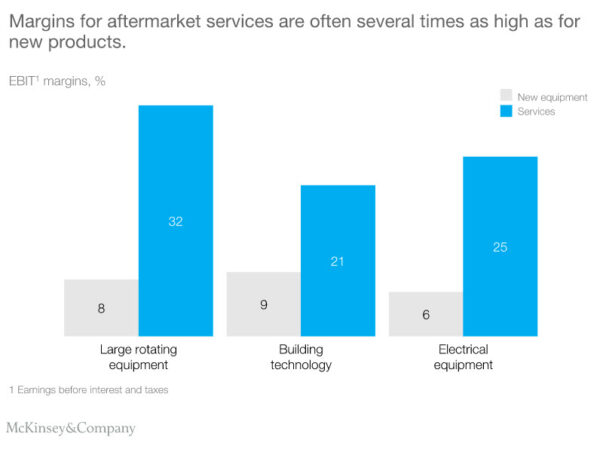

When you’re in heavy equipment, your margins on new product sales are tight. It’s the nature of your business, as you’re selling highly configurable, specialized machines that require significant engineering effort and that will come in low volumes. Margins for fleet maintenance and aftermarket services, on the other hand, are generally several times higher (see figure 1).

Besides, during economic downturns, many companies focus on preserving cash and reducing capital expenditures to make sure they can bridge any short- and medium-term business impacts. So, the demand for new equipment usually declines. That is in fact happening today, as we are in the wake of the COVID-19 pandemic and in the middle of a serious geopolitical crisis. Fleet maintenance and aftermarket services are typically less sensitive to such circumstances and can continue providing stable cash flows, even in times when economic activity is slow.4

That, combined with the advantageous margins, makes upscaling your activities in fleet maintenance and field services an utterly interesting business strategy in the current economic climate.

Reason 2: Your brand is on the line

“It takes 20 years to build a reputation and five minutes to ruin it. If you think about that, you’ll do things differently,” once said Warren Buffett.

Imagine how a corn farmer would react to you, as their equipment supplier, if at the start of the harvest season, his or her combine breaks down. In construction, the average downtime cost for a dump truck is estimated at $448-$760 per day, per vehicle.6 But it can be worse. One of our customers, OneSubsea Processing, a Schlumberger company, makes machinery for subsea production and recovery of oil and gas. Even a short downtime could paralyze an entire oil and gas drilling field, causing the loss of millions of dollars. Read more about it in this analyst report by CIMdata.

As an OEM, you better follow up closely, because your brand image is directly tied to your machines’ performance. The impact of malfunction on your customers’ prime interests, such as their revenue, is immediately visible. So, they expect you to approach the ideal of zero harm, zero emissions, and zero unexpected downtime.

Reason 3: new-generation machinery requires OEM involvement in fleet maintenance

The massive innovations that are currently taking place add both fleet maintenance opportunities and challenges for OEMs. The industry is transitioning from making predominantly hydro-mechanical machines to producing systems-of-systems – software-driven, electrified, highly connected machines. As an OEM, you are the ones who have deep knowledge about those new, innovative products, as opposed to third parties. So, your involvement as an OEM is critical.

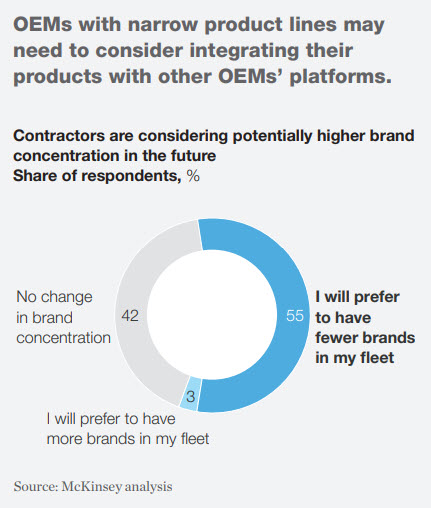

In addition, because of continuous software maintenance needs and upgrade requirements, your presence as an OEM who provides these services will become much more prevalent in the field. And there will be fewer of you around, as many of your customers foresee themselves shifting to a higher brand concentration in future as communications between individual pieces of equipment becomes more important (see figure 2).3

Gradually, this strong presence will automatically make you more of a solution partner to your customers rather than a product seller only. But this new status will come with a responsibility. Many of the new data-driven technologies, particularly those related to autonomous capabilities, will push a greater share of ownership and liability in your direction.7 To be able to provide proof points of good practice in case of litigation, you will need to track all individual pieces of equipment throughout their entire lifecycle and document all decisions and changes, including those related to maintenance.

Reason 4: The OEM is uniquely positioned to take fleet maintenance to the next level

The latter calls for extending the scope of the Digital Twin into fleet maintenance and aftermarket services. The Digital Twin is comprised of a comprehensive set of virtual models and data that represent an individual physical asset in its current environment and state. Throughout the entire product lifecycle, from concept to design, to delivery, and beyond, the Digital Twin stays in sync with its physical counterpart and can mimic its real behavior.

The Digital Twin is rapidly gaining ground across industries as a leading paradigm for several product engineering aspects, including design and manufacturing in the first place. It’s the only way to master the complexity of today’s products, which is due to the massive introduction of digital technologies, multidisciplinary, and mass customization. Making service engineering become a part of that approach, presents unique opportunities which only OEMs can fully capitalize on. Those can truly take fleet maintenance to the next level.

For example, the Digital Twin will help you close the loop between design and service engineering, which basically means that you can organize feedback in both directions. In this way, you can compare asset performance data from design with analytics results on real data, to anticipate service needs and prevent unplanned downtime (like in predictive maintenance). You can use service information to validate as-maintained configurations and ensure continued quality and compliance for equipment in the field. And, you can leverage service data to improve the design of the next generation of products for reliability, serviceable architecture, ergonomics, and more. These are just some of the many possible applications the Digital Twin can enable, and for which you as an OEM are uniquely positioned.

The need for a connected service lifecycle management solution

It’s clear that you cannot get such applications properly orchestrated without having a thorough service-oriented strategy in place, supported by an infrastructure that facilitates the associated bi-directional data streams between disciplines. Connected service lifecycle management (SLM) is exactly about establishing this link between asset configuration management and service requirements and all available design, engineering, and manufacturing data.

Some of the examples above, where you achieve synergies through bi-directional collaboration between disciplines, may seem complicated as they assume that various departments within your organization are tightly integrated during their daily operations. Maybe for your organization, that is still a work in progress. Still, even solely considering the downstream part of it, OEMs who have a proper SLM process in place, can differentiate themselves when providing service.

For example, you as an OEM are the only one who has knowledge about the original design and the full configuration of each machine out in the field. If you can capture that knowledge in an SLM environment as part of a Digital Twin, you can leverage a Digital Thread to streamline maintenance activities by anticipating and delivering the right resources, tools, and necessary parts to the service location before the machine technician arrives. This can save a massive amount of time and cost. And it is something that is becoming increasingly important as configuration complexity for heavy equipment keeps growing.

Teamcenter Service Lifecycle Management by Siemens

At Siemens, we provide such a connected SLM approach through Teamcenter™ software, the PLM solution of Xcelerator™, our comprehensive and integrated portfolio of software and services. Teamcenter is the digital backbone that connects people and processes, across functional silos, and thereby establishes a Digital Thread that spans all lifecycle phases to enable innovation. Teamcenter Service Lifecycle Management will strengthen your competitive position for the delivery of fleet maintenance and aftermarket services.

The solution allows you to truly adopt service as part of your product engineering strategy, by:

- Providing a service view for the Bills of Materials (BOM) to clearly capture all serviceability requirements

- Creating service documentation linked and aligned to the existing design definition

- Developing service requirements and instructions tied to engineering change processes

- Creating and managing physical structures to accurately capture and manage fielded asset configurations and maintenance requirements

- Improving collaboration between service planning and execution

All of this will help you minimize downtime, improve quality, and reduce inventory costs through accurate service instructions and spare part information. It will allow you to introduce new value-driven business models to your customers that provide greater convenience and higher transparency.

Finally, as we realize that either you or your customers may have other partners in their ecosystem, Teamcenter is an open platform that welcomes data from any third party or homegrown solution to participate in service engineering through SLM. In this way, you can deploy Teamcenter Service Lifecycle Management on a scale that fits the needs of your organization.

Conclusion

Especially during these difficult economic times, as an OEM, you must upscale your presence in fleet maintenance activities and aftermarket services. We gave you 4 good reasons:

- additional revenue

- your brand is on the line

- the increasing complexity of the next-generation machinery

- you can deliver unique benefits

To be effective and successful as an OEM with fleet maintenance, you need connected SLM.

Within Teamcenter, we have the perfect SLM solution for any OEM organization.

Stay tuned for my next blog on how connected service life cycle management can help you drive better performance and increase revenues.

Learn More

Try Teamcenter Service Lifecycle Management for free, start your 30-day software trial

For a complete list of Service Lifecycle Management virtual seminars and dates, go here

Read more blogs about Service Lifecycle Management

Learn how Siemens can help address complexity in the Heavy Equipment industry.

References

- OEM Maintenance vs. Third-Party Maintenance: Pros and Cons of Both

- “For OEMs in the United States, the aftermarket is fertile ground,” McKinsey&Company, 2018.

- “How OEMs can seize the high-tech future in agriculture and construction,” McKinsey&Company, 2018.

- “Aftermarket services: transforming manufacturing in the wake of the COVID-19 pandemic,” Deloitte Insights, 2020.

- “Aftermarket Services: The near-term growth opportunity in targeting the right customers,” McKinsey&Company, 2019.

- Cost of construction downtime: what causes it & how do you avoid it?

- Autonomous construction equipment IP and liability issues